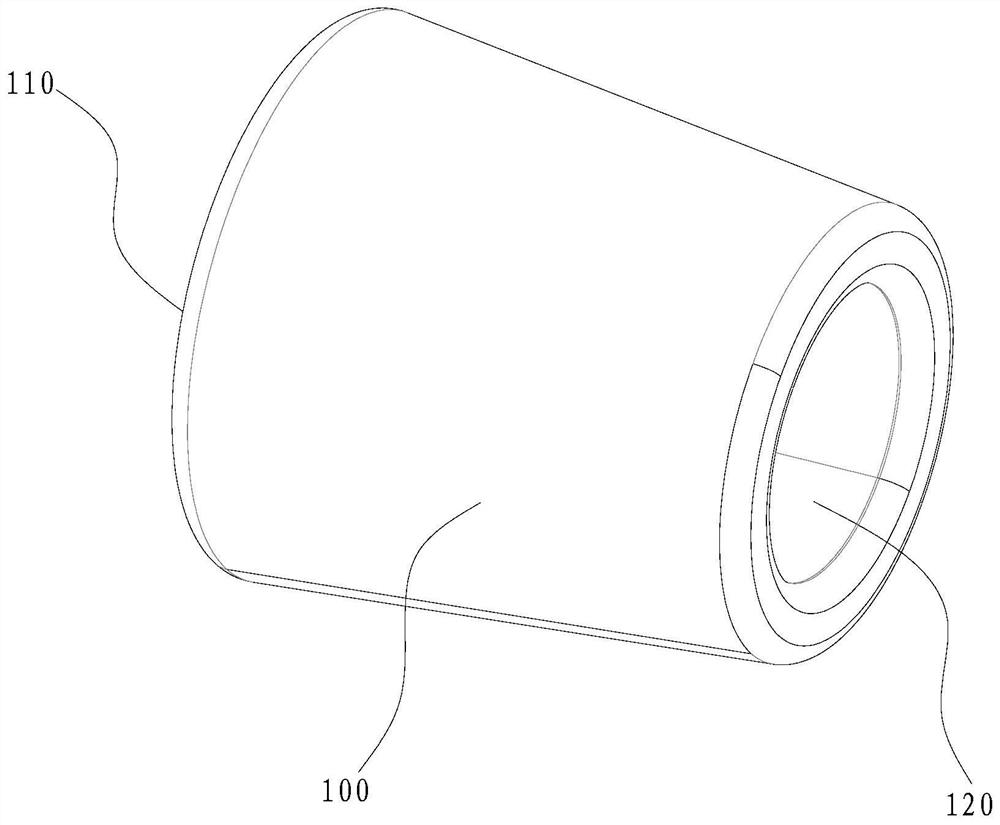

Tool and equipment for disassembling and assembling tuyere medium sleeve of iron-making blast furnace

A tuyere-in-sleeve, iron-making blast furnace technology, applied in tuyere, lifting devices, manufacturing tools, etc., can solve problems such as the structural strength, service life and stability of the installation machine head itself, the tuyere mid-sleeve falling off, and potential safety hazards. , to achieve the effect of improving the clamping and fixing effect, improving the supporting effect and reducing the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

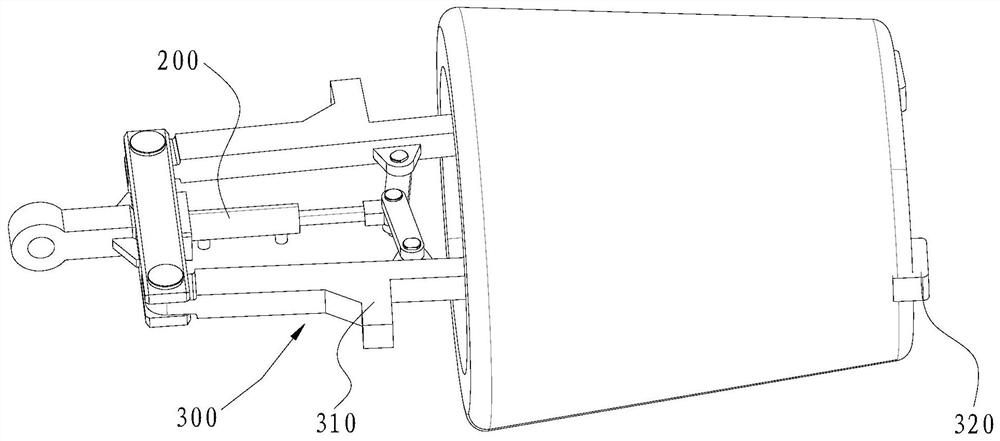

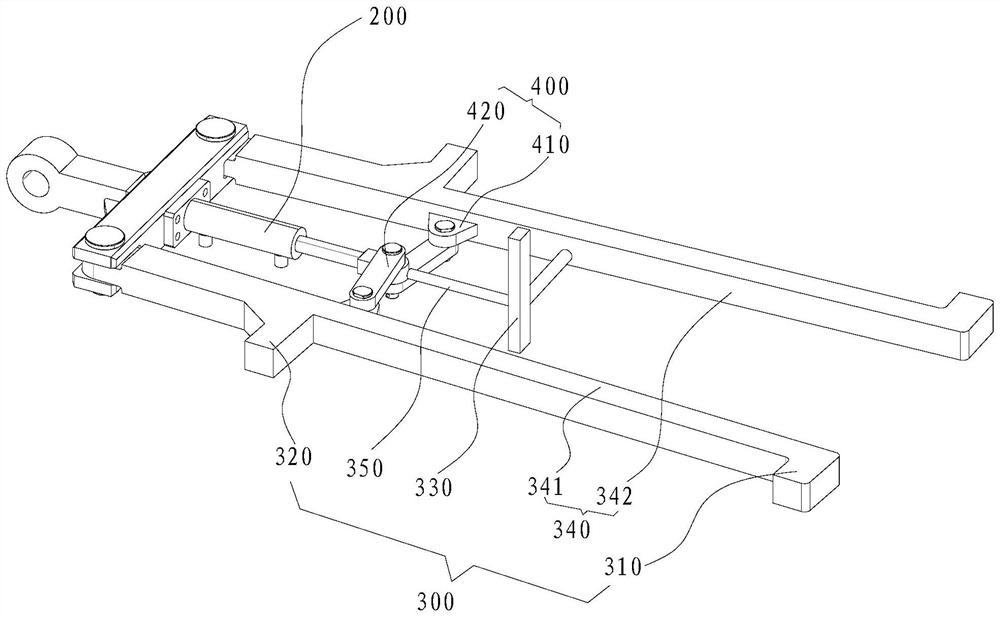

[0050] refer to image 3 As shown, the grabbing device 300 in this example may include a clamping arm 340, the support member 330 is rotatably disposed on the clamping arm 340, and the support member 330 has an inner wall against the inner sleeve 100 of the tuyere. The support state is connected and the release state is separated from the inner wall of the sleeve 100 in the tuyere.

[0051] The supporting member 330 is rotatably disposed on the clamping arm 340 so that the supporting member 330 can rotate relative to the clamping arm 340 so that the supporting member 330 has a supporting state and a releasing state. In the supported state, the support member 330 can support the tuyere middle cover 100, and avoid the possibility of the tuyere middle cover 100 shaking to the greatest extent; Separated and rotated to a suitable position to provide convenience for subsequent disassembly and assembly actions, it can also make the material space occupied by the grabbing device 300 ...

example 2

[0057] refer to Figure 4 As shown, the difference between the second example and the first example above is that the clamping arm 340 is provided with an elastic member 343 and a slider 344, wherein the slider 344 is connected with the elastic member 343 and the connecting rod in the grabbing device 300 respectively. 350 are connected, and the connecting rod 350 can make the sliding block 344 slide back and forth along the clamping arm 340 under the driving action of the driving device 200 .

[0058] When the grabbing device 300 is in the locked position, the slider 344 abuts against the bottom of the support 330, so that the support 330 stands up to be in a supporting state; when the grabbing device 300 is in the unlocked position, the slider 344 is in contact with the support The supporting part 330 is separated, and the supporting part 330 returns to the horizontal under the elastic force of the elastic part 343 so that it is in a released state.

[0059] It should be not...

Embodiment approach

[0062] As a preferred embodiment of the present invention, the car body 500 may also include a gantry frame 520, the gantry frame 520 is provided with a transverse guide rail 521 and a vertical guide rail 522, and the rotating seat 510 and the vertical guide rail 522 for sliding fit, so that the tooling moves up and down along the gantry 520;

[0063] The equipment provided by this application for disassembling and assembling the tuyeres of ironmaking blast furnaces enables the tooling to have a variety of different motion states relative to the car body 500 , so that the tooling can be lifted to disassemble and assemble the tuyeres 100 in different positions or postures , so that the equipment has a wider environmental adaptability, and provides convenience for the actual work process of workers.

[0064] The places not mentioned in the present invention can be realized by adopting or referring to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com