Insulation structure of wrench

An insulating structure and wrench technology, which is applied in the field of hand tools, can solve the problems that do not meet the needs of actual use, the trouble of repairing the internal components of the casing 11, and the time delaying the disassembly of the fasteners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

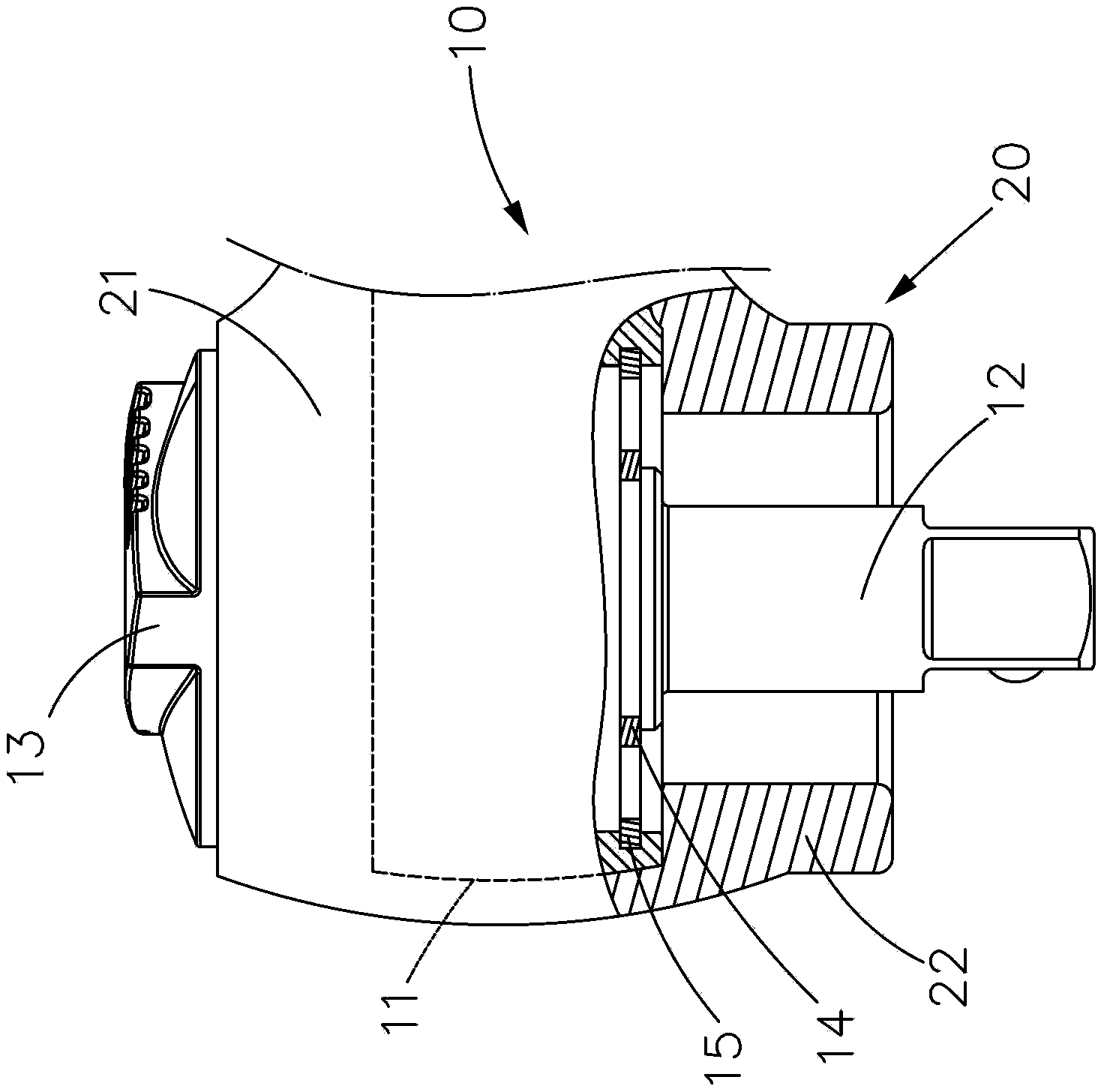

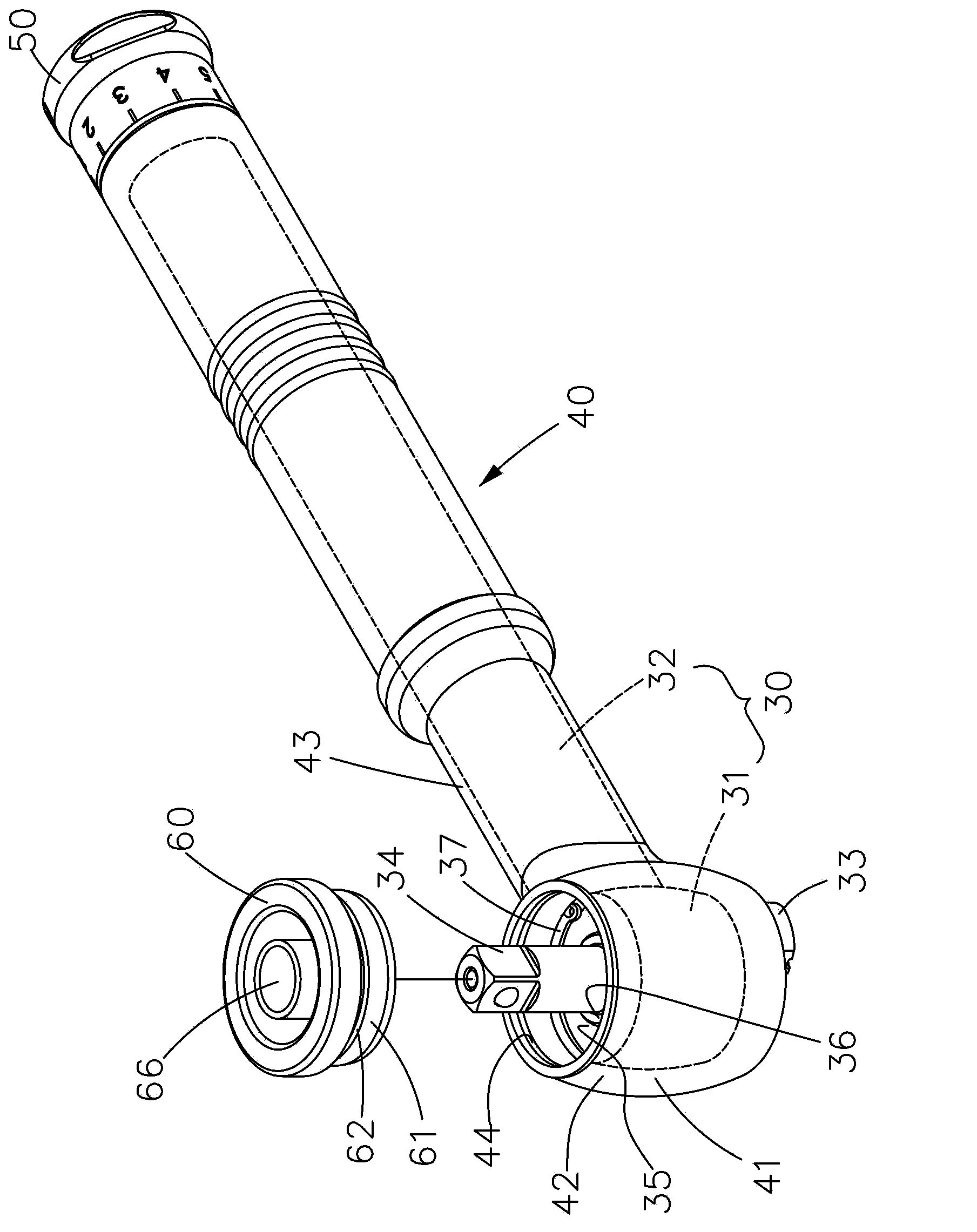

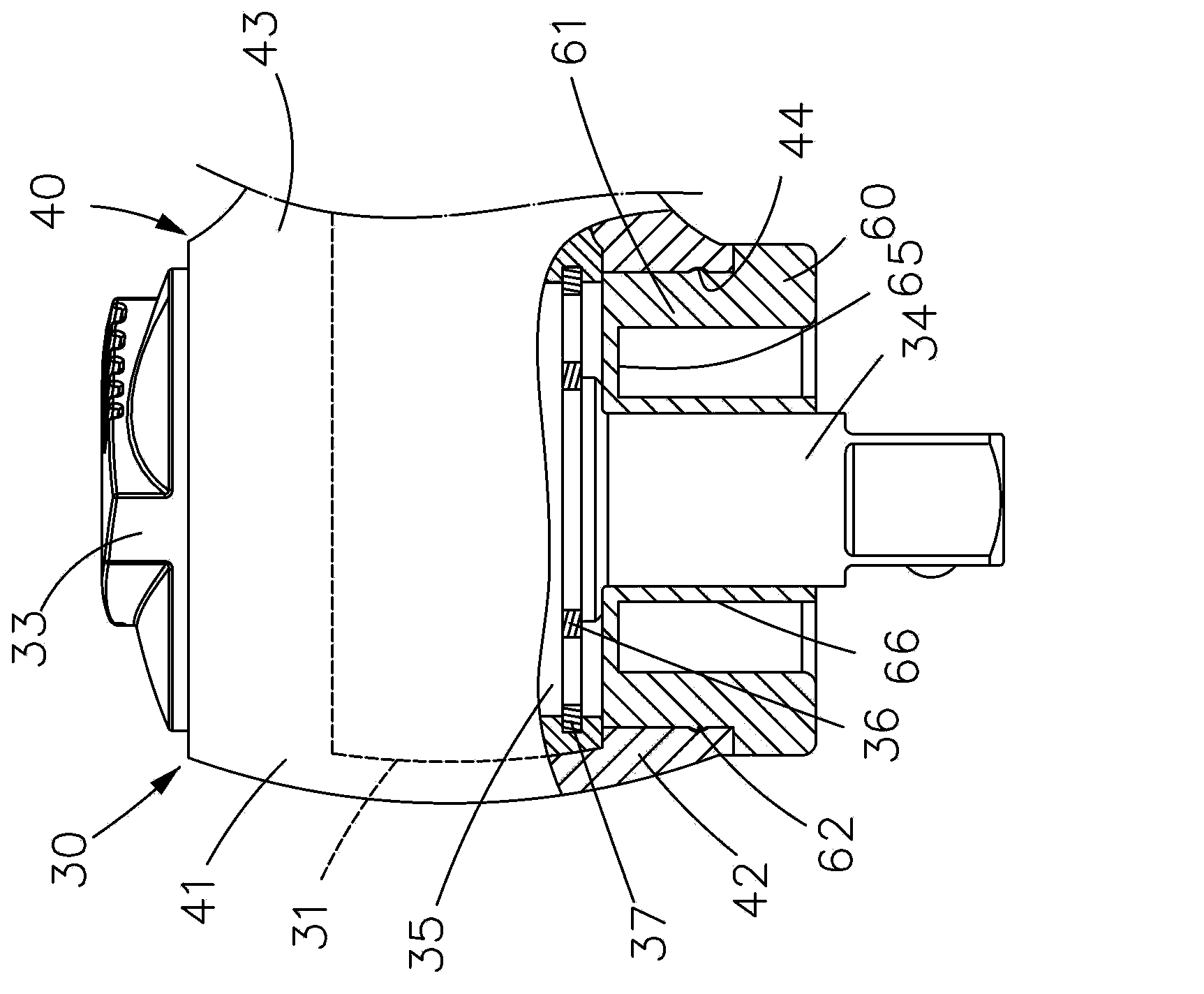

[0023] The present invention is a wrench insulating structure. In the accompanying drawings illustrating specific embodiments of the present invention and its components, all references to front and rear, left and right, top and bottom, upper and lower, and horizontal and vertical are only It is used for convenience of description and does not limit the invention, nor its components, to any position or orientation in space. The dimensions specified in the drawings and description can be changed according to the design and requirements of the specific embodiments of the present invention without departing from the patent scope of the present invention.

[0024] Wrench insulating structure of the present invention, as figure 2 , image 3 As shown, the wrench has a wrench head 30 with a drive assembly inside and a handle 32 integrally connected, wherein the handle 32 is locked into the end by an adjustment button 50, so that the handle 32 can be turned and applied force and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com