Internal structure of maglev vacuum pipeline

A vacuum pipeline and internal structure technology, applied in the direction of roads, tracks, tunnel systems, etc., can solve the problems of small pipeline diameter and insufficient research on single-pipe and double-line pipelines, so as to reduce the blocking ratio, improve the evacuation and maintenance function, and reduce the lateral The effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

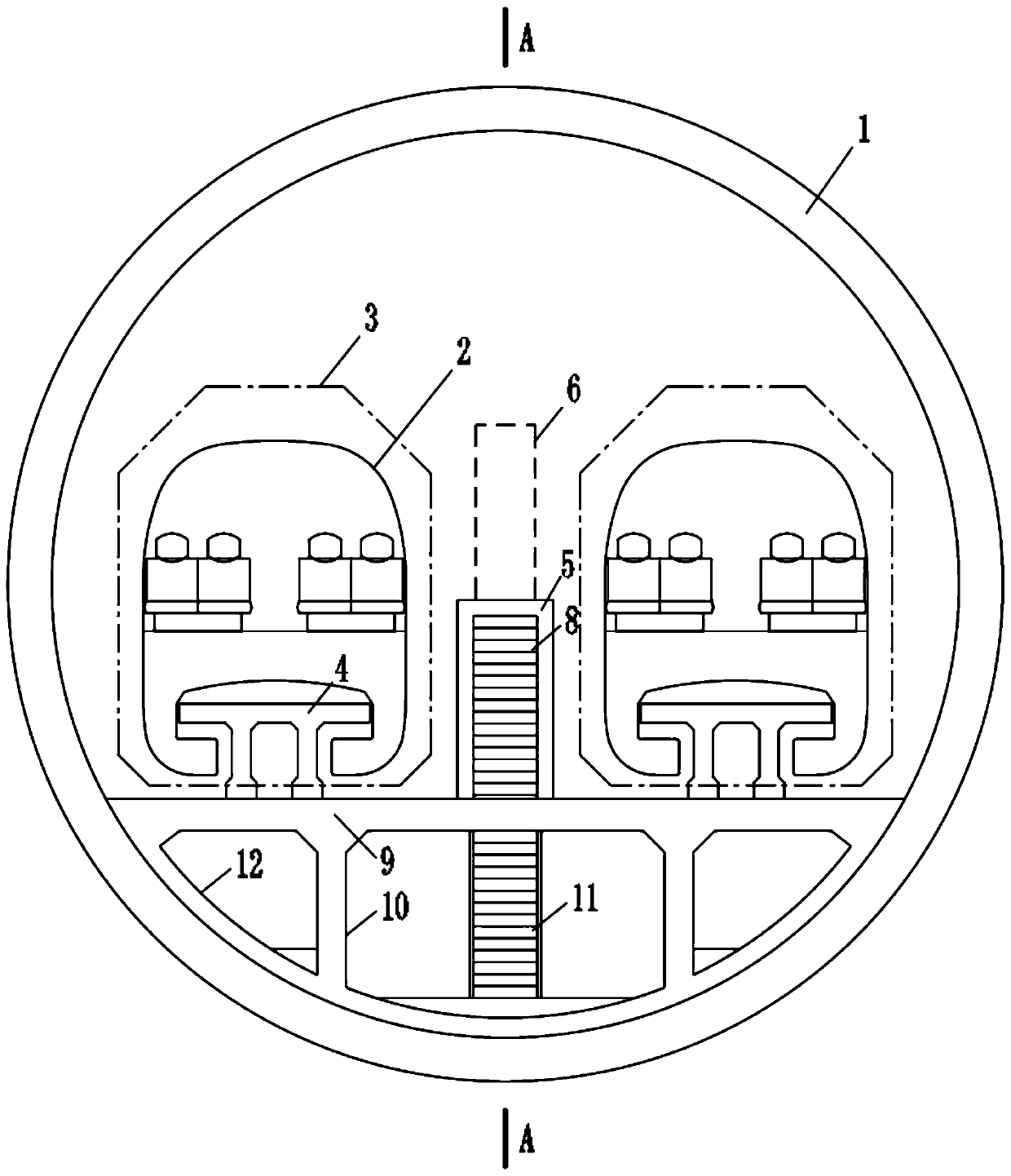

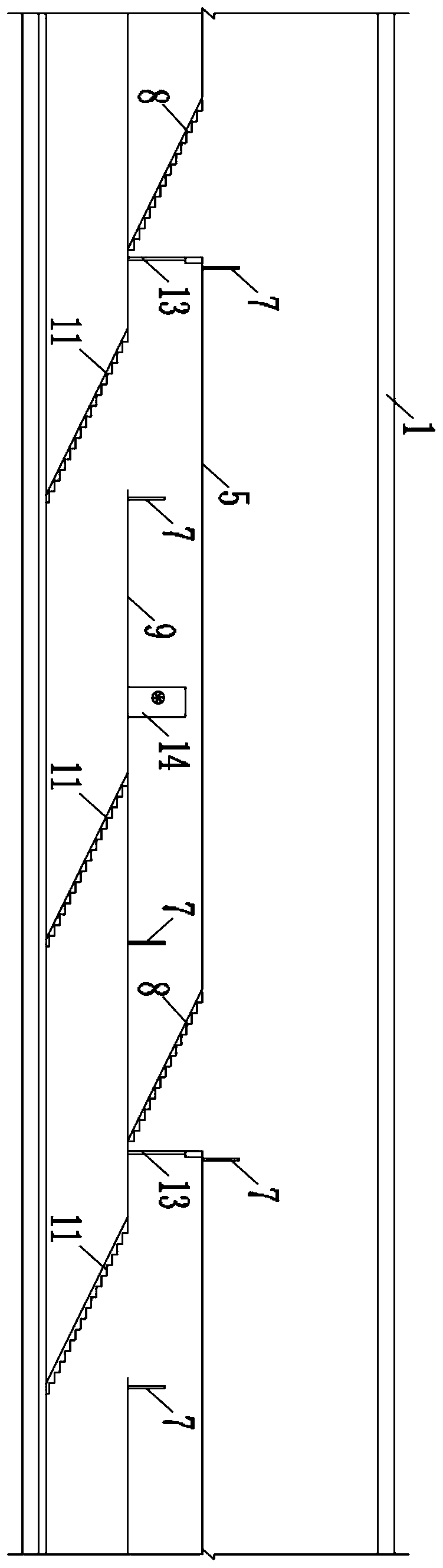

[0031] Embodiment one, such as Figure 1-2 Shown:

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings. The internal structure of the maglev vacuum pipeline includes a main pipeline structure 1. The main structure 1 of the maglev vacuum pipeline bears the external load, and the inner bottom of the main pipeline structure 1 is set through along its length direction. The under-rail structure 9, the top of the under-rail structure 9 is provided with an inter-rail channel 5, and maglev tracks 4 located on both sides of the inter-rail channel 5, the ultra-high-speed maglev train 2 can run bidirectionally on the maglev track 4, and the two columns of maglev tracks 4 are respectively Located on both sides of the inter-rail channel 5, the setting of the inter-rail channel 5 can not only reduce the lateral force effect when the two vehicles meet, ensure the safety of vehicle operation, but also facilitate the evacuation of perso...

Embodiment 2

[0036] The inter-rail channel 5 is a closed structure connected with the under-rail structure 9, which is convenient for staff to overhaul the operating equipment in the under-rail structure 9.

Embodiment 3

[0038] The inter-rail passage 5 is an evacuation structure with a partially open roof. The top plate of the inter-rail passage 5 is provided with openings every 50-100m. Open the inter-rail passage door 13 to enter the space from the inter-rail passage 5 to the top plate of the under-rail structure 9, which not only meets the operation requirements of the vacuum pipeline ultra-high-speed maglev train, but also forms a stable and convenient evacuation or maintenance passage in a vacuum environment. To facilitate the evacuation of personnel in the platform safety space 6 and enter the space between the inter-rail passage 5 and the top plate of the under-rail structure 9; the side walls of the inter-rail passage 5 are respectively provided with inter-rail passage side wall doors 14 for personnel to enter from the under-rail structure. 9 The top surface is directly evacuated or overhauled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com