Novel two-ferrule tube fitting

A double ferrule type and pipe joint technology, which is applied in the connection, design and manufacture, and sealing fields of pressure-resistant and circular pipes, can solve the problems of large installation torque and affect popularization and application, and achieve strong pressure resistance and connection The effect of strong strength, reducing harsh requirements and technical requirements for installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

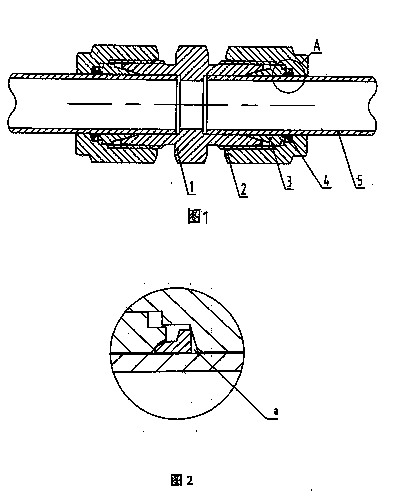

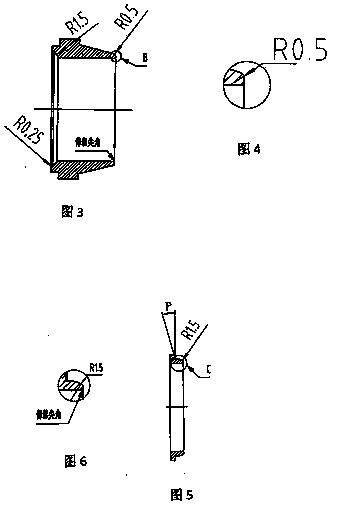

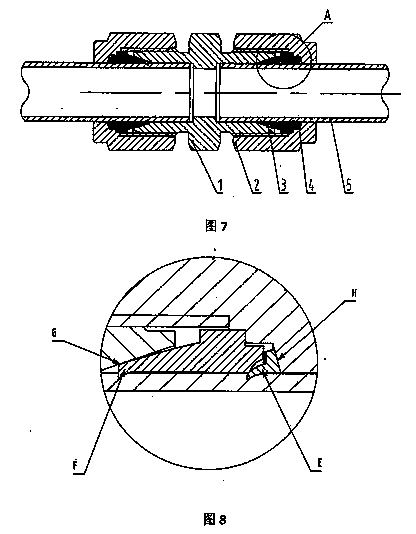

[0023] 1. A new double ferrule type pipe joint, which is composed of a joint body (1), a nut (2), a front ferrule (3), and a rear ferrule (4). It is characterized in that: the front ferrule (3) The front end (B) is matched with the bell mouth of the joint body, the front end (C) of the rear ferrule (4) is in contact with the inner arc surface of the rear end of the front ferrule (3), and the nut (2) is screwed into the joint body (1) so that The bottom slope of the nut (2) coincides with the rear end of the rear ferrule (4) and leaves an included angle (a); insert the pipe (5) to be connected from the tail of the nut (2) and withstand the joint body (1 ) inner step, when the nut (2) is rotated and tightened, the nut (2) moves forward and pushes the rear ferrule (4) to drive the front ferrule (3) forward, the front end (G) of the front ferrule (3) Under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com