Novel chromium-free self-lubricating coloring aluminum coating for aviation as well as preparation method and application thereof

An aluminum coating and self-lubricating technology, applied in anti-corrosion coatings, coatings, devices for coating liquids on surfaces, etc. , process instability and other problems, to achieve the effect of improving maintainability, reducing friction coefficient, and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]

[0042]

[0043] The preparation method of the present embodiment is as follows:

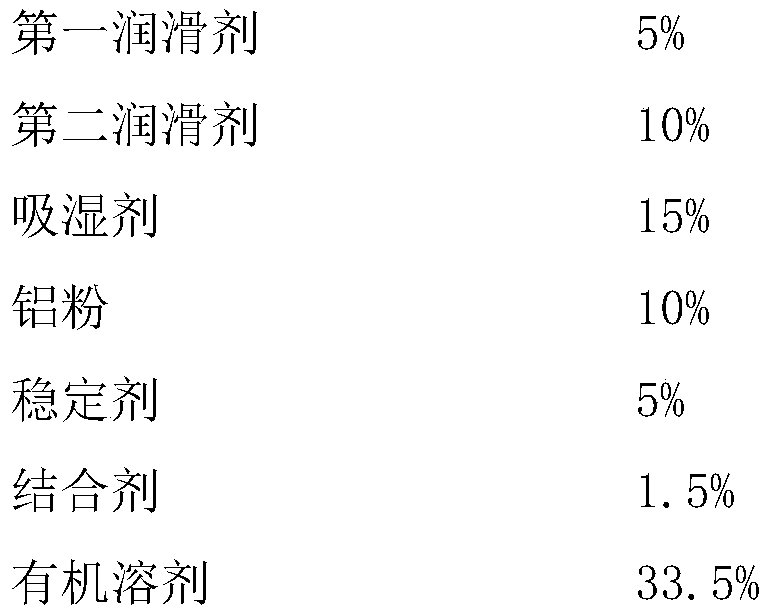

[0044] A. Mix 10% aluminum powder with 20% modified phenolic resin, 33.5% organic solvent butanone, and 1.5% binder butyraldehyde, and stir for 20- 30min;

[0045] B. Add 5% of the first lubricant molybdenum disulfide, 10% of the second amount of lubricant polytetrafluoroethylene, 15% of hygroscopic agent acetic acid, and 5% of stabilizer dibasic lead phosphite into A, Stir with a pneumatic stirring gun for 10 minutes at a speed of 1000-2000r / min;

[0046] C. Add B into the grinder, grind for 55 minutes at a speed of 4500-5000r / min, and obtain the finished coating after filtering. The appearance of the paint color is silver, which is close to the color number 26380 in the FED-STD-595 "U.S. Federal Color Card".

[0047] The aluminum coating prepared in this embodiment, during application, refer to the following steps:

[0048] a. After degreasing the parts, use 120-220 mesh coru...

Embodiment 2

[0061]

[0062] The preparation method of the present embodiment is as follows:

[0063] A. Mix 8% aluminum powder with 30% modified phenolic resin, 30.7% organic solvent butanone, and 1.3% binder butyraldehyde, and stir for 20 minutes at a speed of 1000-1500 r / min with a pneumatic stirring gun;

[0064] B, the first lubricant molybdenum disulfide of 3.5%, the second lubricant polytetrafluoroethylene of 8%, the hygroscopic agent acetic acid of 15%, the stabilizer dibasic lead phosphite of 3.5% join in A, use Pneumatic stirring gun stirred at a speed of 1000-2000r / min for 8 minutes;

[0065] C. Add B into the grinder, grind for 50 minutes at a speed of 4500-5000r / min, and obtain the finished coating after filtering. The appearance of the paint color is silver, which is close to the color number 26380 in the FED-STD-595 "U.S. Federal Color Card".

[0066] During the application of the aluminum paint of the present embodiment, its steps are:

[0067] a. After degreasing the...

Embodiment 3

[0080]

[0081] The preparation method of the present embodiment is as follows:

[0082] A. Mix 5% aluminum powder with 40% modified phenolic resin, 35% organic solvent butanone, and 1% binder butyraldehyde, and stir for 20- 30min;

[0083] B, 2% of the first lubricant molybdenum disulfide, 5% of the second lubricant polytetrafluoroethylene, 10% of hygroscopic agent acetic acid, 2% of stabilizer dibasic lead phosphite are added to A, with Pneumatic stirring gun stirs for 12min at the speed of 1000-2000r / min;

[0084]C. Add B into the grinder, grind for 58min at a speed of 4500-5000r / min, and obtain the finished coating after filtering. The appearance of the paint color is silver, which is close to the color number 26380 in the FED-STD-595 "U.S. Federal Color Card".

[0085] During the application of the novel chrome-free self-lubricating colored aluminum paint of the present embodiment, its steps are:

[0086] a. After degreasing the parts, use 120-220 mesh corundum san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com