Hydraulic pipeline pipe end forming connector

A technology of pipe end forming and hydraulic pipeline, applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, passing through components, etc., can solve the problems of large installation torque, many parts and components, affecting popularization and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

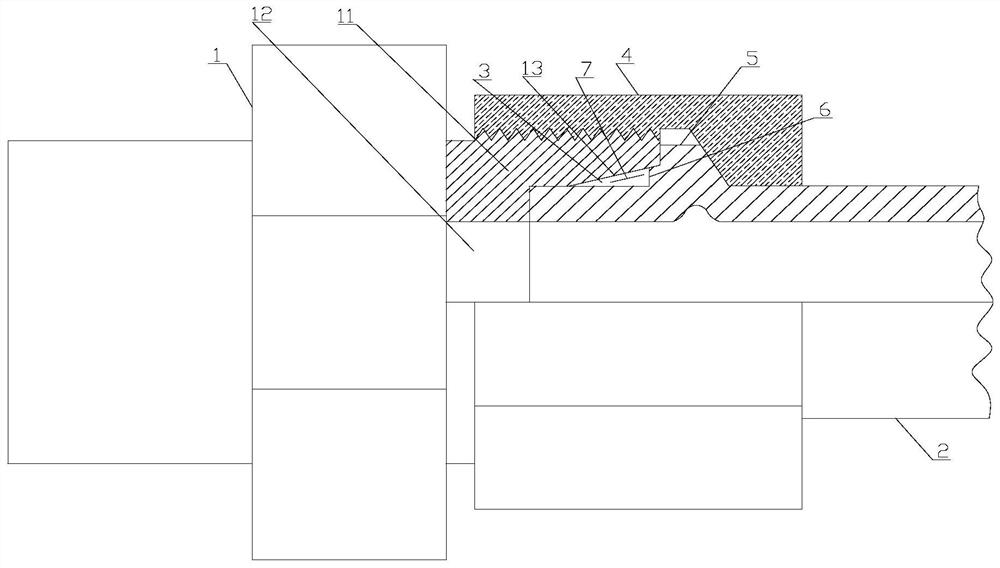

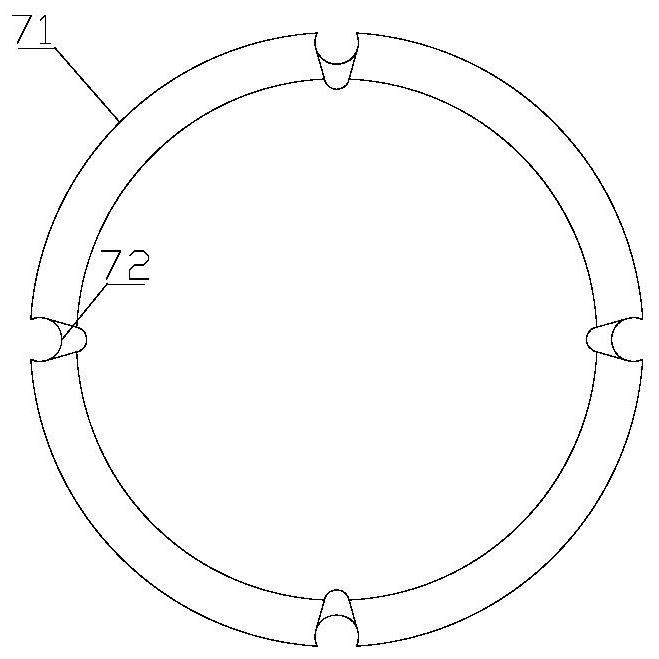

[0017] refer to figure 1 , 2 , a hydraulic pipeline pipe end forming connector according to the present invention, comprising a joint body 1, a pipe body 2, a sealing ring 3 and a nut 4, the joint body 1 includes a connecting part 11 provided with an external thread, and the connecting part 11 There is a stepped hole 12 with a small front and a large rear, the rear end of the stepped hole 12 is a tapered hole 13, and the pipe end of the pipe body 2 is formed with a ring-shaped anti-off protrusion 5 through a cold forming process. The pipe body 2 in front of the ring-shaped anti-off protrusion 5 is provided with a sealing ring 3 that matches the tapered hole 13, and the pipe body 2 behind the ring-shaped anti-off protrusion 5 is provided with a screw thread with the connecting portion 11. Connected nut 4, the front end of the annular anti-off protrusion 5 is provided with a tapered sealing portion 6 that is in close contact with the tapered hole 13, the sealing ring 3 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com