Internal circulation type locomotive LED lamp head structure

A technology of LED lamp head and internal circulation, which is applied in the direction of motor vehicles, road vehicles, lighting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

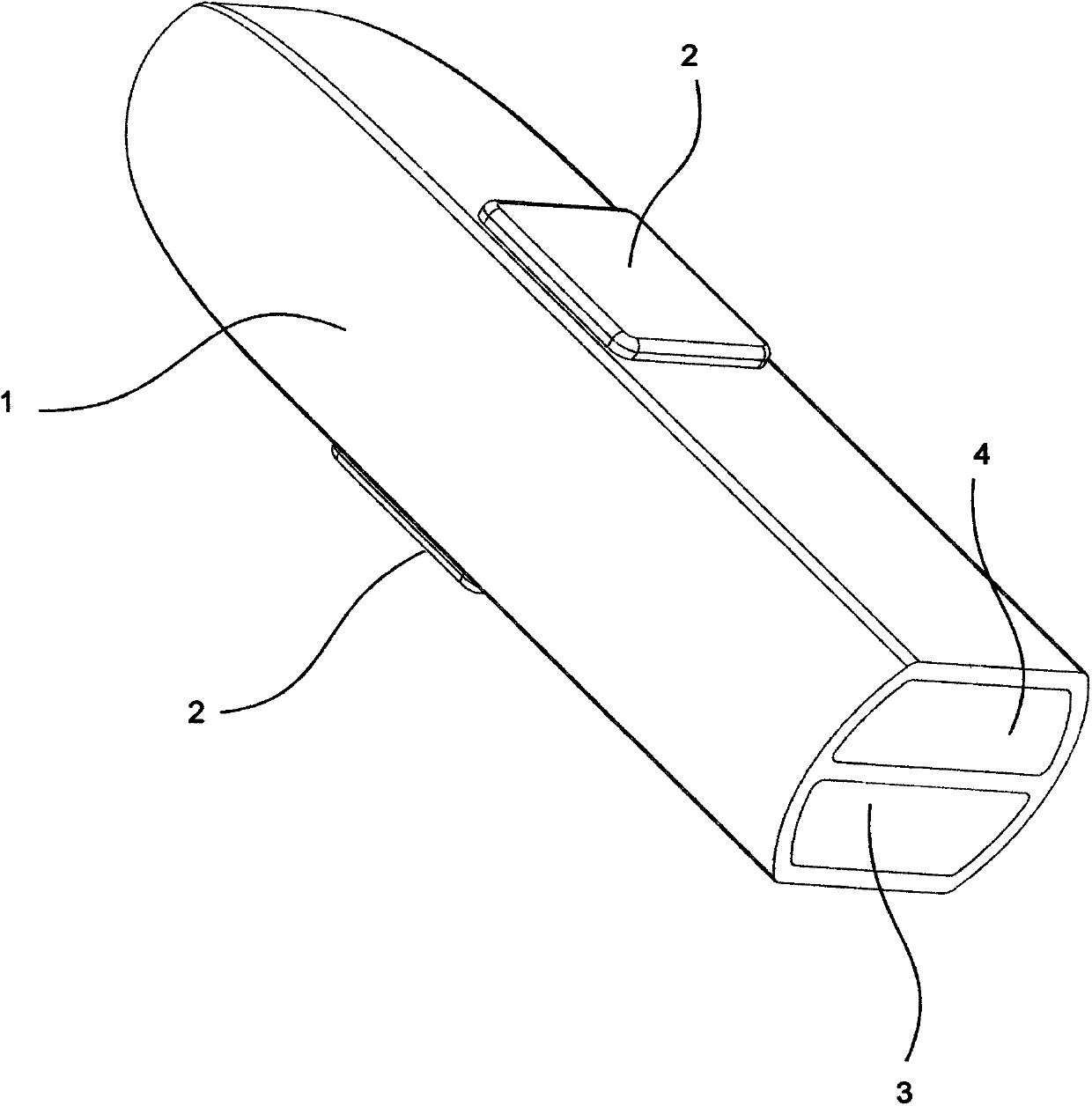

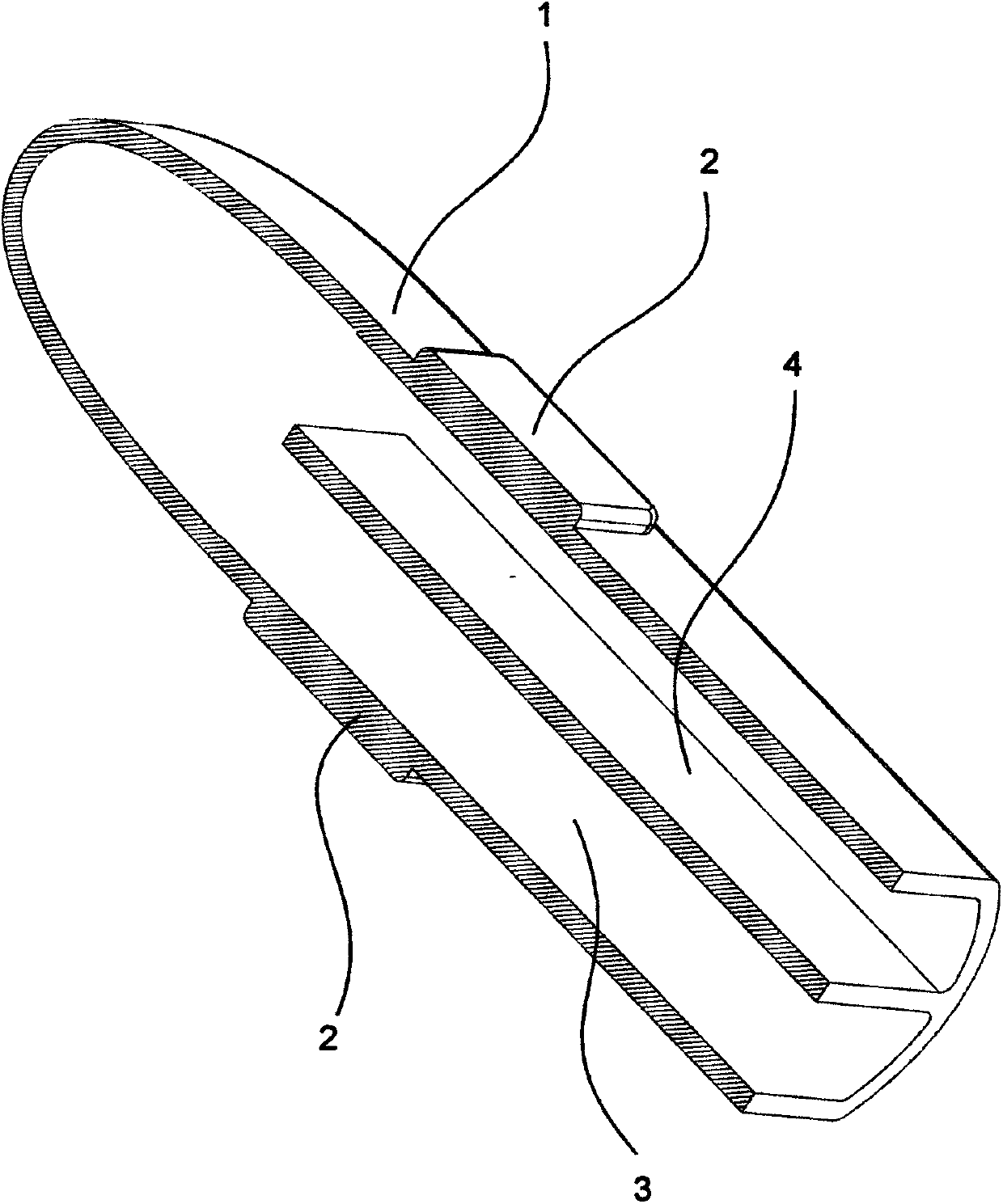

[0011] The schematic diagram of the appearance of the structure of the LED lamp head of the inner circulation type locomotive of the present invention is as follows: figure 1 As shown: It is composed of LED lamp holder 1, LED light source 2, inlet channel 3, outlet channel 4 and other main components.

[0012] The mechanical relationship is as follows: the LED light source 2 is fixedly connected to the outside of the LED lamp cap 1, and the interior of the LED lamp cap 1 is isolated into the inlet channel 3 and the outlet channel 4, and the ends of the inlet channel 3 and the outlet channel 4 are connected. Schematic such as figure 2 shown.

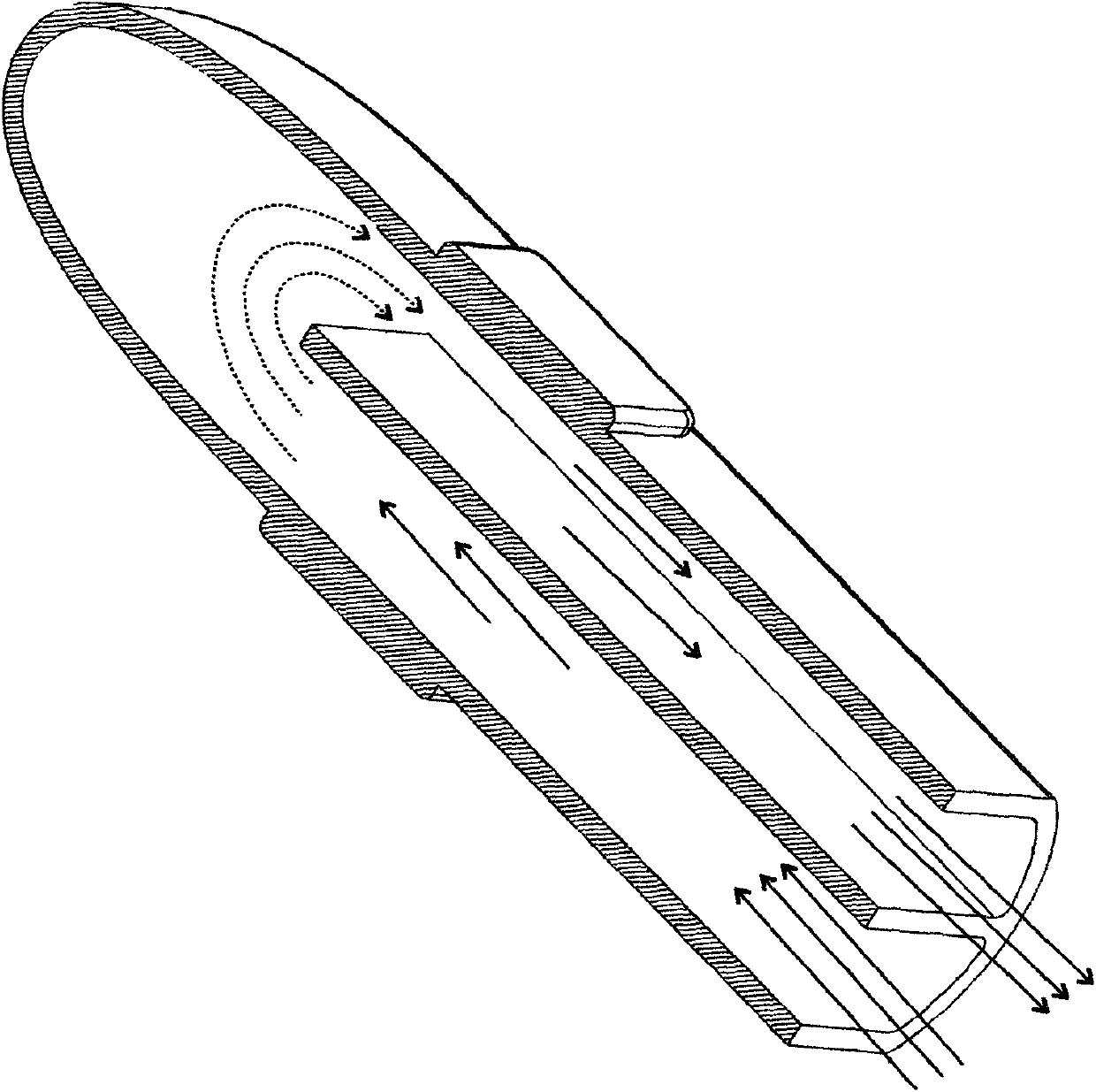

[0013] working principle:

[0014] When the motorcycle LED light of the present invention is working, the LED light source 2 emits light and generates a large amount of heat. The end of the flow channel 3 flows back into the outlet channel 4, and flows through the entire LED lamp head 1 again, and then flows out of the LED lamp head 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com