Marine high-speed pump water spraying force model for blade load fine control and design method thereof

A fine-control, high-speed pump technology, which is applied in the field of high-speed pump injection and design, and pump injection propulsion, can solve the problems of unretrieved related patents and inability to finely control blade load distribution, so as to promote popularization and application and improve anti-cavitation performance, the effect of increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

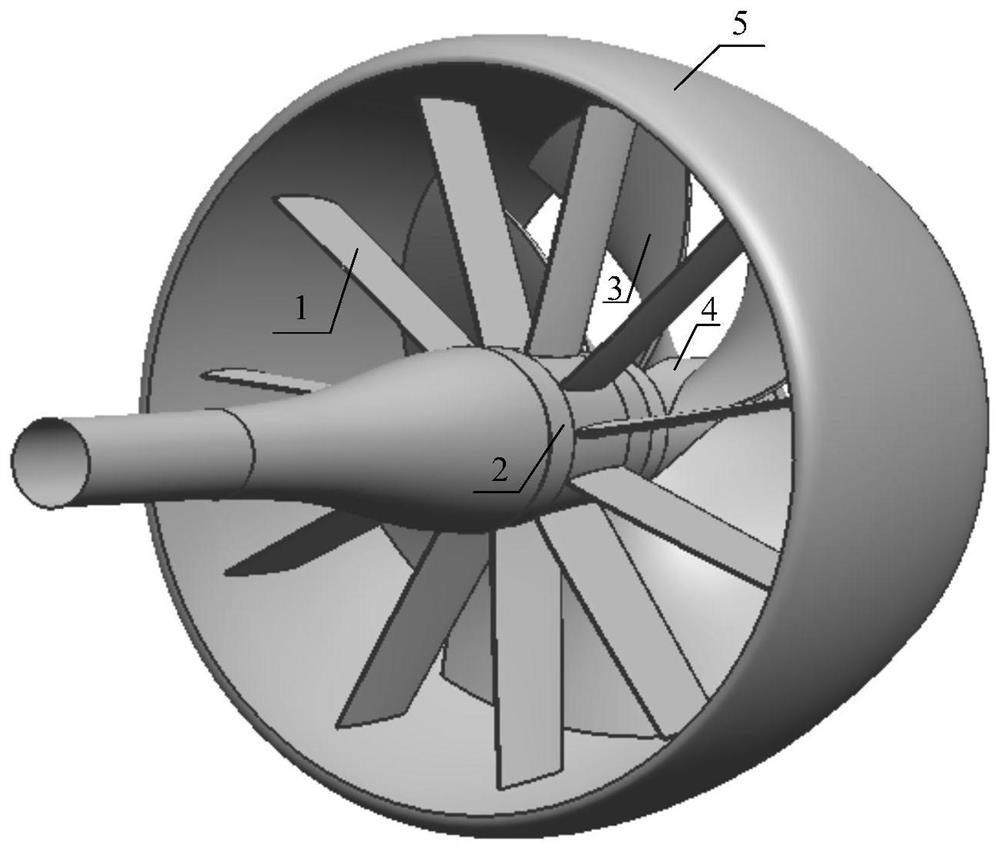

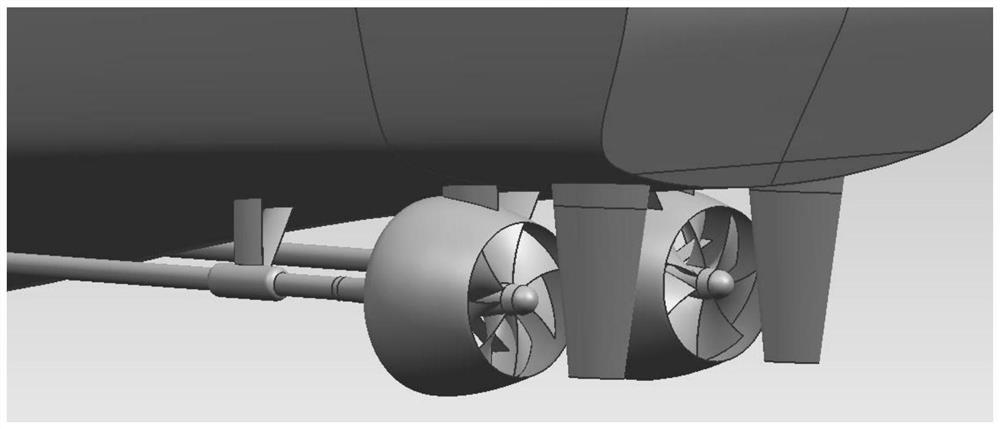

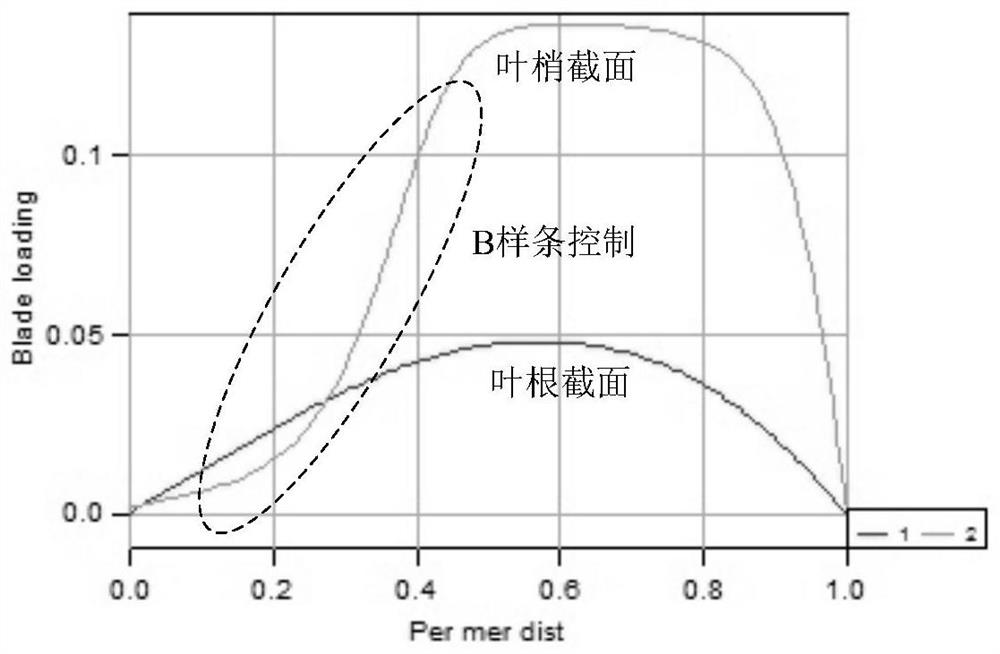

[0037] pass below Figure 1 to Figure 6 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

[0038] The flow chart of the marine high-speed pump jet hydraulic model design method of the fine control of blade load designed by the present invention is as follows Figure 6 as shown,

[0039] Step S1, according to the design requirements, carry out the type selection design of the hydraulic parameters of the pump fluid channel, and determine the five parameters of the pump spray cascade channel's head, flow rate, outlet area, specific speed and suction port specific speed parameters.

[0040] Step S2, determine the two-dimensional axial plane projection geometry of the pump spray front stator, rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com