Solar thermal storage system

A heat storage system and solar energy technology, applied in the field of solar heat storage systems, can solve problems such as temperature imbalance of heat storage units and low heat storage efficiency of heat storage systems, and achieve low production costs, high heat storage efficiency, and increased heat exchange area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

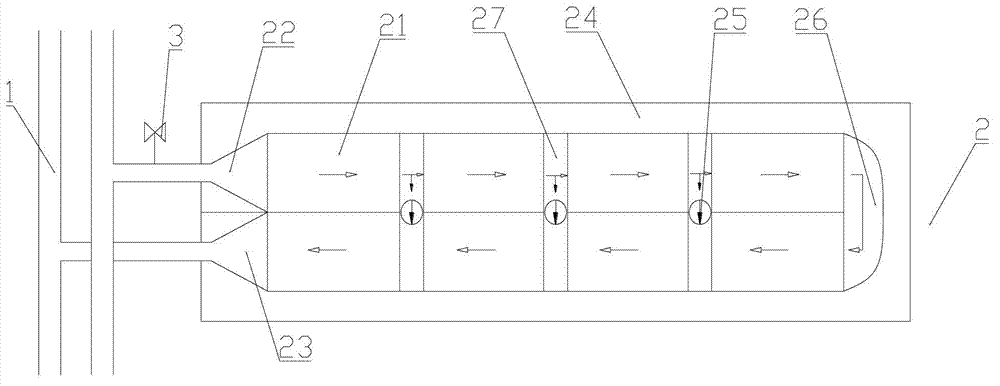

[0049] figure 1 The solar heat storage system of the present invention includes a heat storage pile 2; the heat storage pile 2 is connected to the main pipeline 1 through an inlet 22 and an outlet 23; the heat storage pile 2 includes a thermally insulated heat storage chamber 24 and The heat storage unit 21 arranged inside the heat storage chamber 24. In this embodiment, two rows of the heat storage units 21 are arranged in the heat storage chamber 24 corresponding to the positions of the inlet 22 and the outlet 23, far away from the heat storage chamber 24. A main channel gap 26 is provided between the end of the heat storage unit 21 of the inlet 22 and the outlet 23 and the inner wall of the rear end of the heat storage chamber 24; a gap 26 is provided between adjacent heat storage units 21 in each row There is an auxiliary channel gap 27; the thermal working medium flows into a row of heat storage units 21 connected to the inlet 22 through the inlet 22, and after passing th...

Embodiment 2

[0054] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the heat storage unit 21 is composed of a plurality of heat storage pipes 215 arranged in a staggered manner and interconnected with each other, and scattered storage pipes 215 arranged between the heat storage pipes 215. Heat medium composition. Between the main passage gap 26 and the auxiliary passage gap 27, a number of stacked ventilation bricks 29 are arranged, and the ventilation bricks 29 are blocks with through holes in four directions.

Embodiment 3

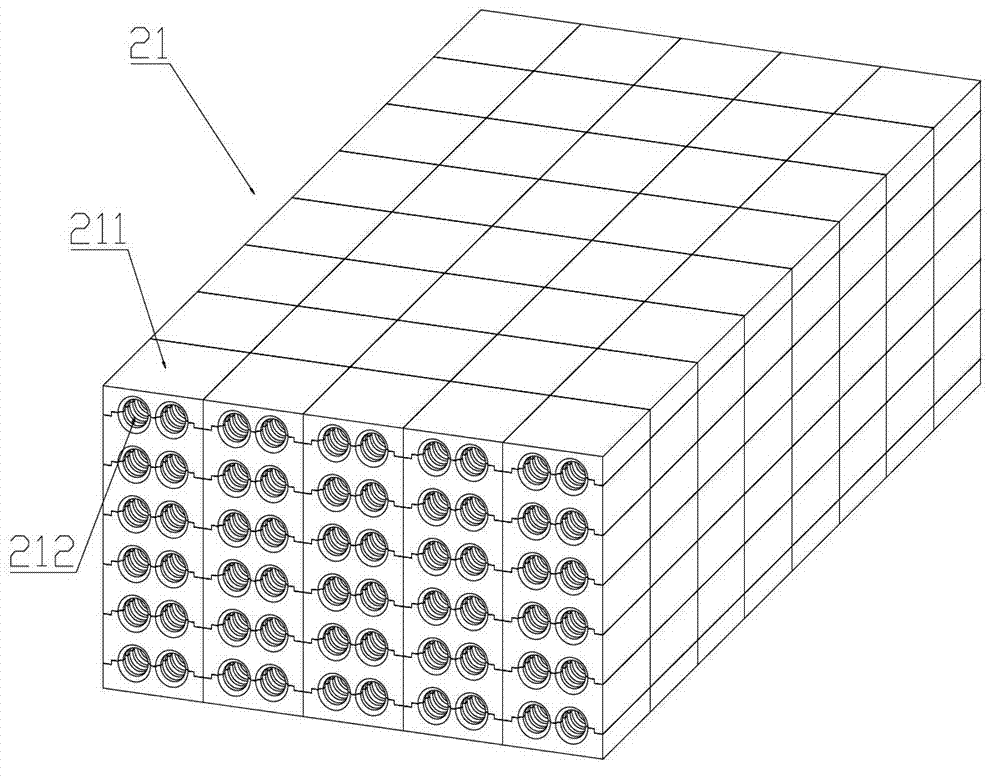

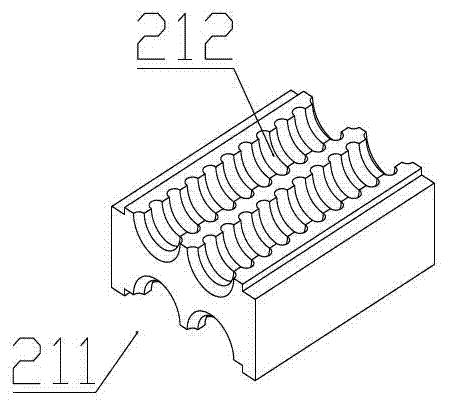

[0056] The structure of this embodiment is basically the same as that of Example 1, the difference is that: the heat storage unit 21 includes a row of heat storage modules 211 and loose heat storage media arranged on both sides of the heat storage modules 211, the heat storage The heat storage medium is sandstone. The surface or inside of the heat storage module 211 is formed with the thermal medium channels 212 communicating with each other horizontally and vertically. Between the main passage gap 26 and the auxiliary passage gap 27, a number of stacked ventilation bricks 29 are arranged, and the ventilation bricks 29 are blocks with through holes in four directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com