Alternating current voltage withstand test device for rubber and plastic cable

A technology of AC withstand voltage and test equipment, applied in the direction of testing dielectric strength, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

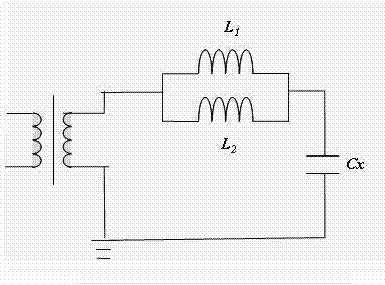

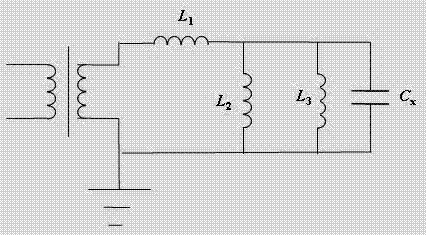

[0013] like figure 2 As shown, the rubber and plastic cable AC withstand voltage test device is composed of 1# reactor L1, 2# reactor L2, 3# reactor L3 and excitation transformer, 1# reactor L1, 2# reactor L2 and 3# reactor The inductance of the reactor L3 is the same, the 2# reactor L2 and the 3# reactor L3 are connected in parallel and connected in series with the 1# reactor L1, and the 2# reactor L2 and the 3# reactor L3 are connected in parallel and connected in series with the 1# reactor L1 The reactor group is connected in parallel at both ends of the output coil of the excitation transformer, one end of the output coil of the excitation transformer is grounded, and the tested cable Cx is connected in parallel at both ends of 2# reactor L2 and 3# reactor L3.

[0014] The inductance of 1# reactor L1, 2# reactor L2 and 3# reactor L3 is 135H, the rated voltage is 130kV, and the rated current is 5A; the rated capacity of the excitation transformer is 75kVA, and the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com