Hydraulic system for construction machinery

A technology for construction machinery and hydraulic systems, applied in the field of hydraulic systems, can solve the problems of deviation of construction machinery from the line, pressure loss, and hydraulic fluid cannot be supplied equally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Matters such as detailed construction and elements defined in the description are merely specific details provided to help those of ordinary skill in the art fully understand the present invention, and the present invention is not limited to the embodiments disclosed hereinafter.

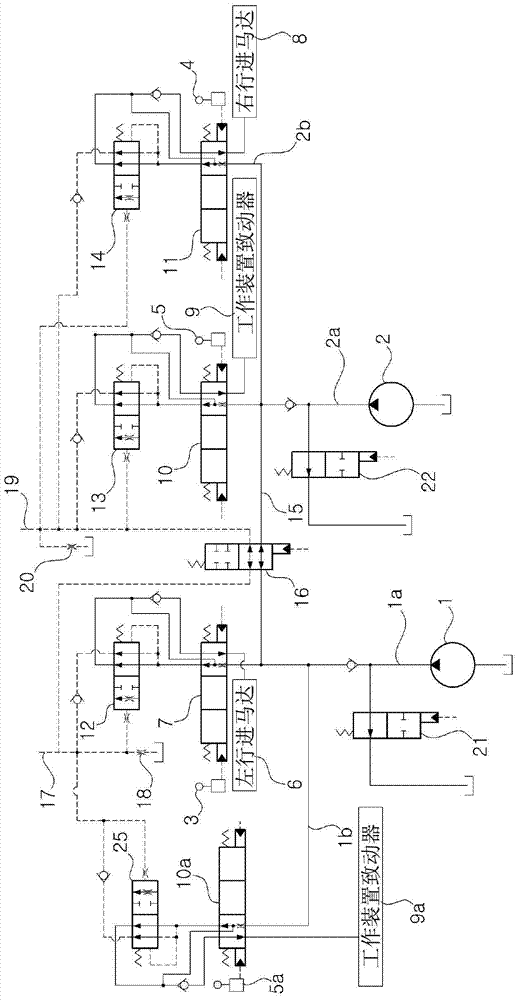

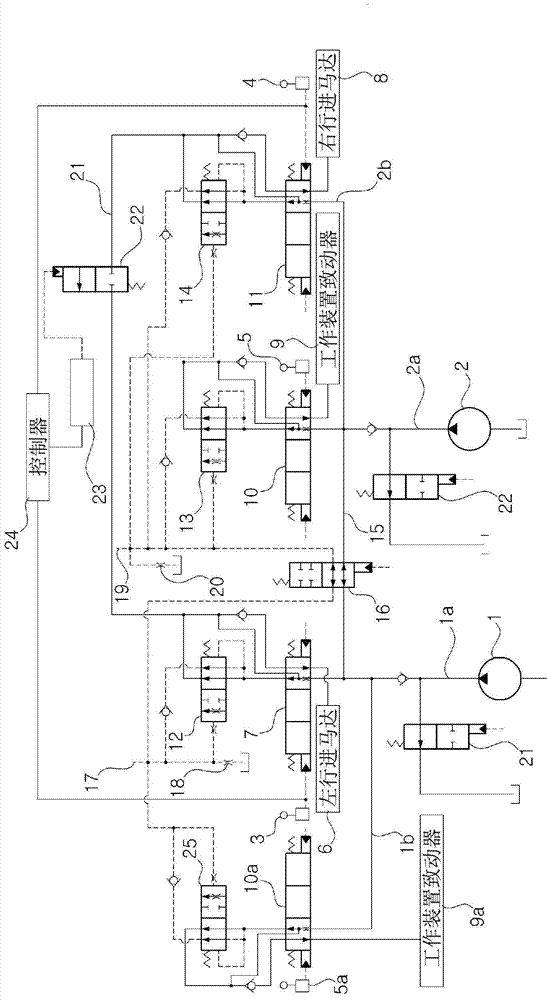

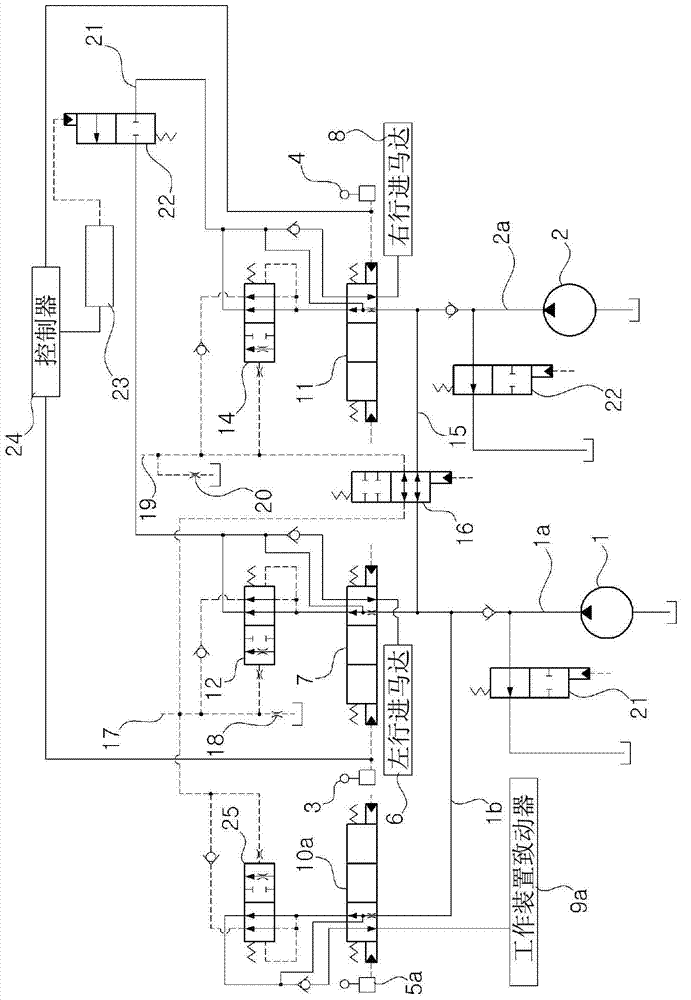

[0056] Such as figure 2 As shown in , the hydraulic system for construction machinery according to the first embodiment of the present invention includes: a first hydraulic pump 1 and a second hydraulic pump 2, connected to an engine (not shown); a left travel operating lever 3, a right The traveling operation lever 4 and the actuator operating lever 5a for the first working device and the actuator operating rod 5 for the second working device output an operation signal proportional to the operator's operation amount; the left traveling motor 6 , is connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap