Bicycle front tripod assembly mold

A tripod and bicycle technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing production efficiency, affecting product quality, welding errors, etc., and achieve convenient rotation and spot welding positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

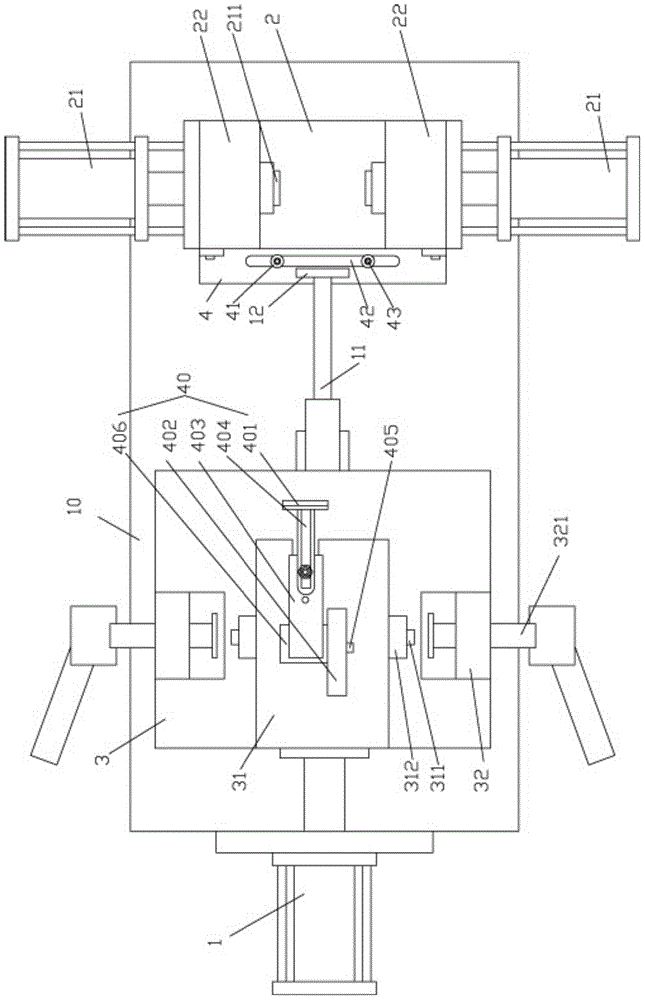

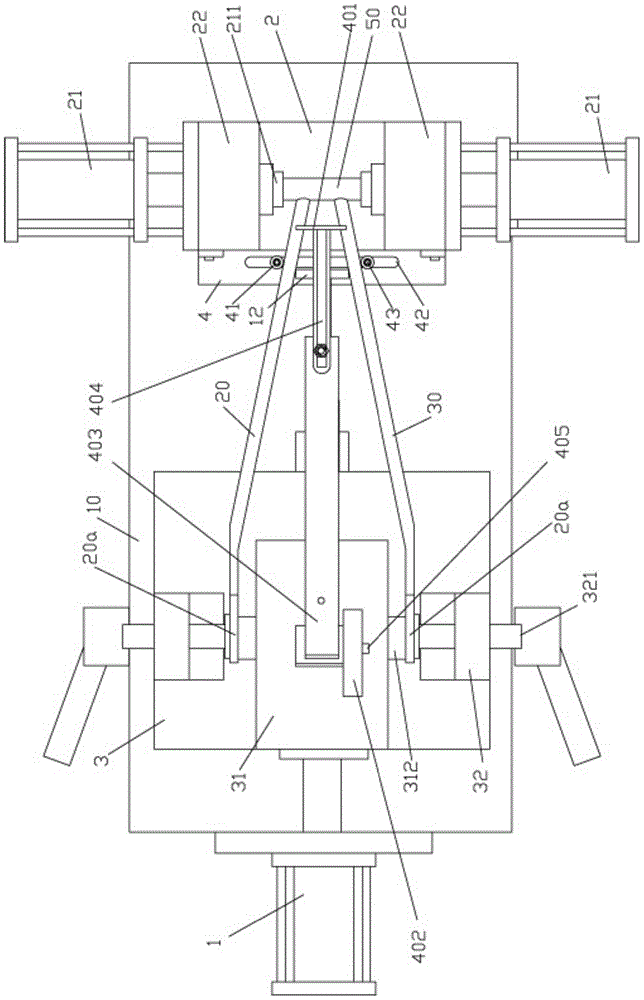

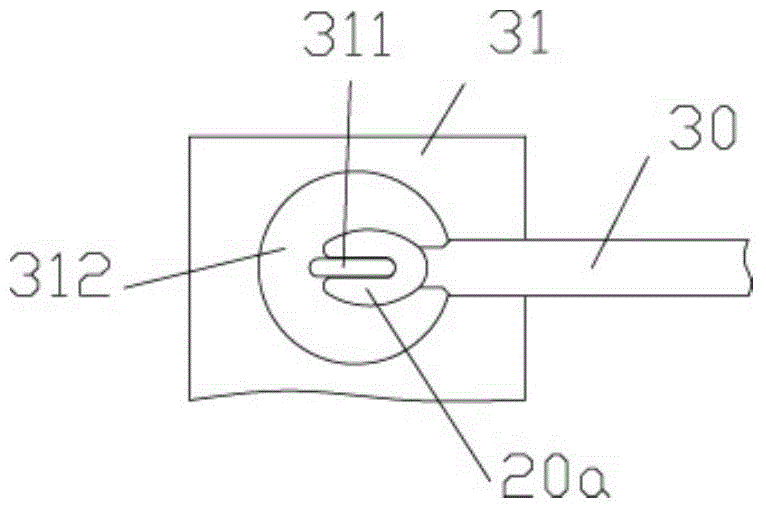

[0027] Example: see Figures 1 to 8 As shown, a bicycle front tripod assembly mold includes a workbench 10 on which a push cylinder 1, a positioning base 2 and a clamp base 3 are fixed, and the push rod 11 of the push cylinder 1 passes through and extends out of the clamp The base 3, the top of the push rod 11 is fixed with an intermediate support rod 12 perpendicular to the push rod 11, the middle part of the clamp base 3 is fixed with a fixed block 31, the left and right sides of the clamp base 3 are fixed with a support block 32, and the left and right sides of the fixed block 31 Protrusions 311 are formed on both sides, and a push rod 321 is inserted into the through hole of the support block 32. The end of the push rod 321 faces the protrusion 311, and the left and right two protrusions 311 are inserted into the front tripod of the bicycle to be assembled. In the front claw 20a of the tail end of the left support rod 20 and the front claw 20a of the tail end of the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com