Four-ring-hole spinneret mold for co-spun yarns

A four-ring hole and spinning technology, which is applied in the direction of ceramic extrusion dies, etc., can solve the problems of weak interlayer bonding, complicated process, and sudden film boundary transition, and achieve strong interlayer bonding, long service life, Simple operation effect

Active Publication Date: 2014-02-26

SHANDONG UNIV OF TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The problem with this structure is that the process of layer-by-layer impregnation and sintering is complex, energy-consuming and time-consuming; Weak binding force, easy to produce

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

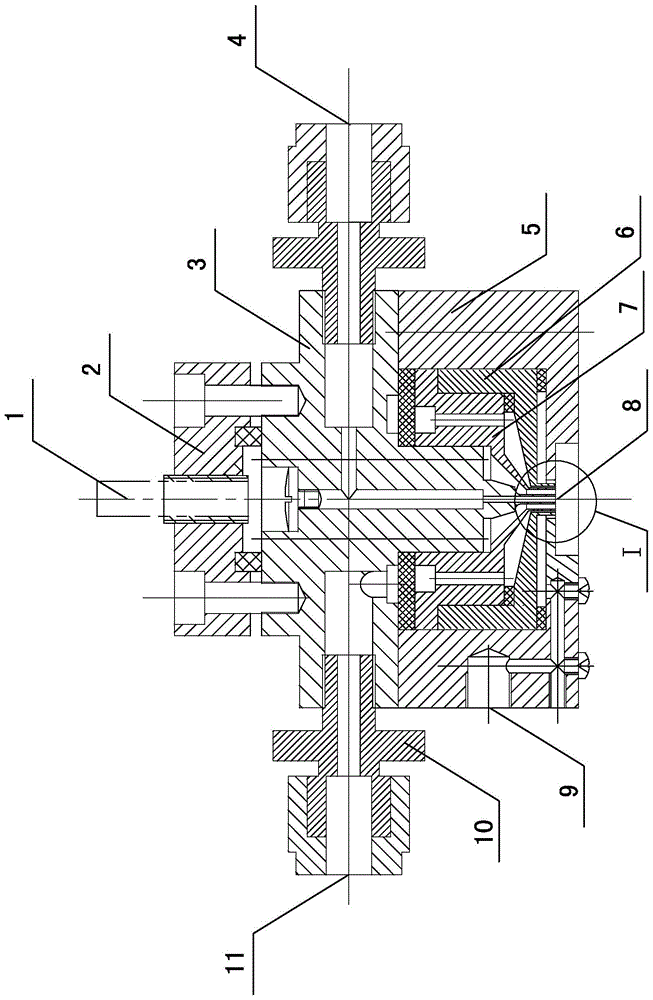

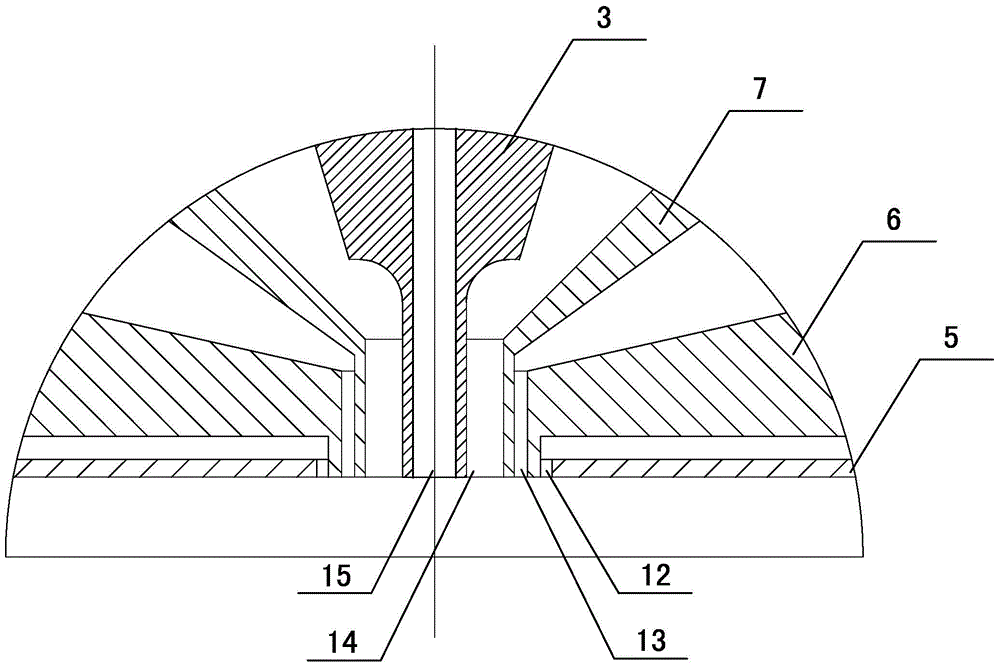

The invention relates to a mold, in particular to a four-ring-hole spinneret mold for co-spun yarns. The four-ring-hole spinneret mold for the co-spun yarns comprises a bottom sleeve, an upper spacer bush, a middle spacer bush and a lower spacer bush, wherein an outlet is formed in the bottom of the bottom sleeve; the lower spacer bush, the middle spacer bush and the upper spacer bush are sequentially arranged in the bottom sleeve; a spacer bush cover is arranged on the upper portion of the upper spacer bush; an inner-layer hole which is connected with the upper spacer bush is formed in the spacer bush cover; a middle-layer hole and an inner gel bath hole are respectively formed in two side walls of the upper spacer bush; an outer-layer hole is formed in the bottom sleeve; the inner-layer hole, the middle-layer hole and the outer-layer hole are not connected with the inner gel bath hole; and the spacer bushes and the bottom sleeve form four channels above the outlet. Compared with the prior art, the four-ring-hole spinneret mold for the co-spun yarns has the advantages that a three-layered composite ceramic micro-pipe can be prepared at one step, the operation is simple, the cost is low, the boundary transition of membrane layers of the prepared three-layered composite ceramic micro-pipe is natural, and the three-layered composite ceramic micro-pipe is high in interlayer binding force, reasonable in structure, not easy to peel and long in service life.

Description

technical field [0001] The invention relates to a die, in particular to a four-ring hole spinning die for co-spinning. Background technique [0002] At present, there are still challenges in the research of multilayer film interface compatibility and current collection for microtubular solid oxide fuel cells, which hinders the development of its industrial application. The first is the multilayer film interface compatibility issue. At present, MT-SOFC (microtubular solid oxidation fuel cell) is mainly prepared by layer-by-layer method. For example, the anode microtube is prepared first, and then the anode functional layer, dense electrolyte membrane, and deposited cathode layer are sequentially prepared on the outside by dipping and sintering method. In order to obtain high battery output performance, the current SOFC technology must contain 5 or more ceramic membrane layers. This requires high ceramic processing technology, especially in the fine microtube structure, whic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B28B3/26

CPCB28B3/2636

Inventor 杨乃涛孟秀霞李永军谭小耀孟波刘少敏

Owner SHANDONG UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com