Optimization control device for chemical phosphorus removal process

A technology for process optimization and chemical phosphorus removal, applied in various fluid ratio control, chemical instruments and methods, water/sewage multi-stage treatment, etc. Difficulty in operation and maintenance, etc., to reduce the risk of exceeding the standard, improve the treatment effect, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

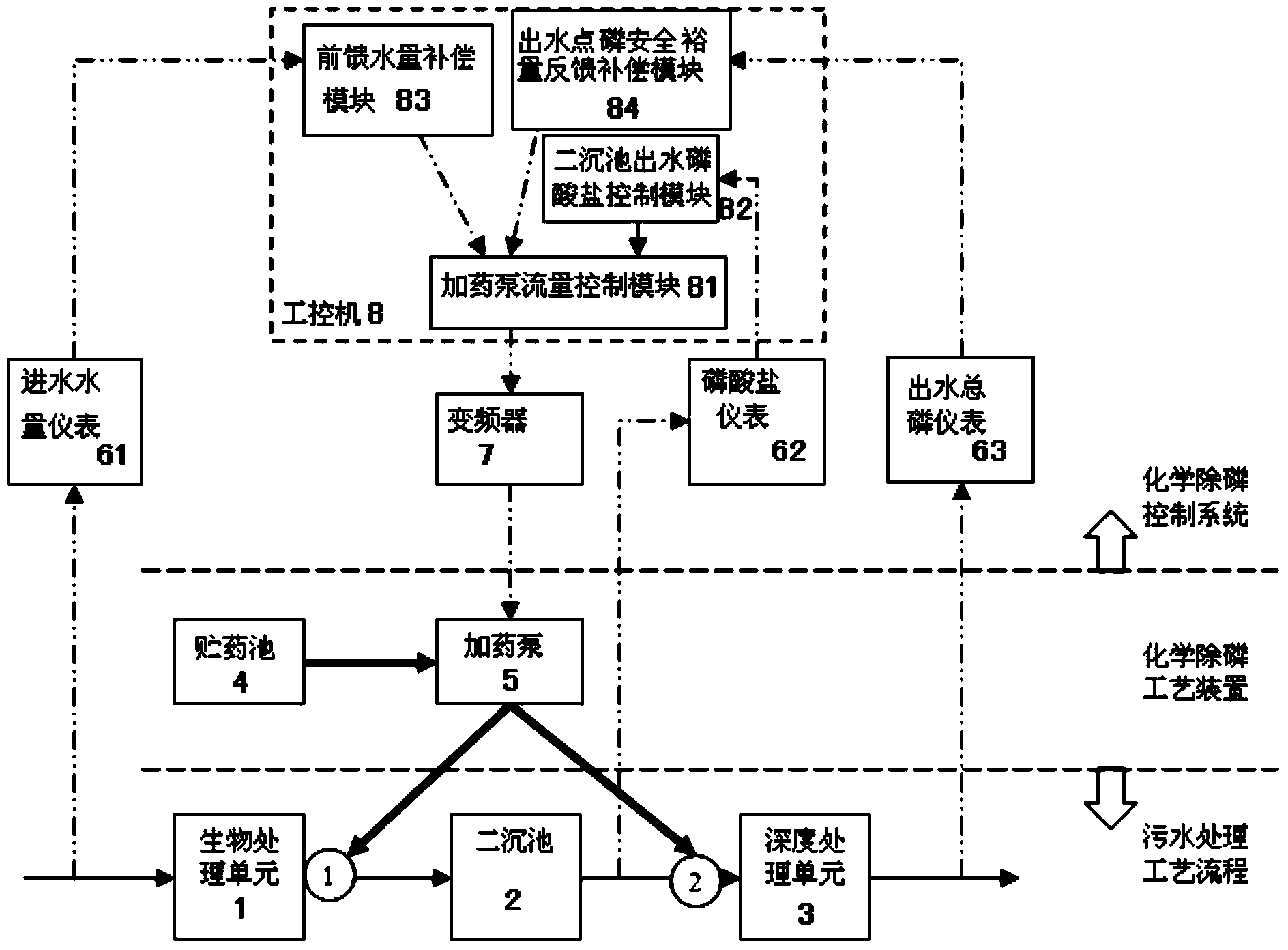

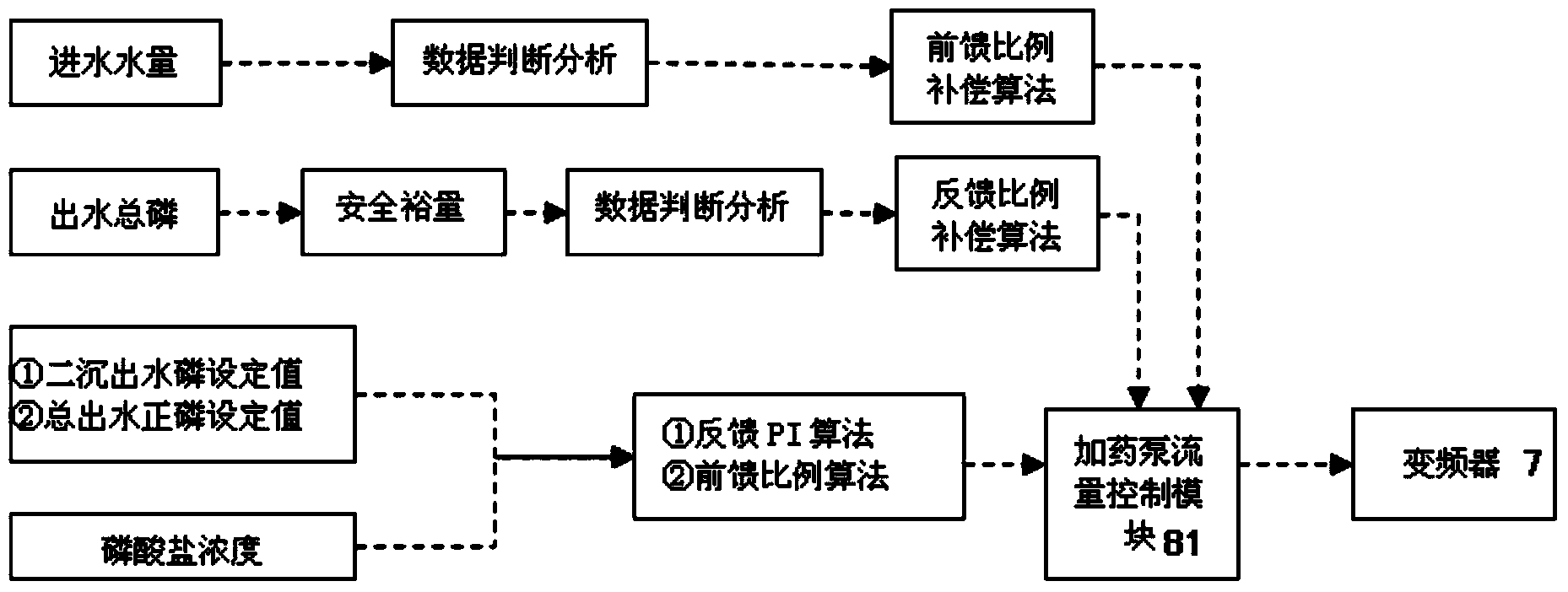

[0063] Process operation status: AA0 process of an urban sewage treatment plant with a scale of 100,000 tons / day, divided into two series, adopting synchronous chemical phosphorus removal process, setting up three phosphorus removal agent dosing pumps 5, and setting the dosing point in the biochemical treatment Outlet of unit 1 ( figure 1 ① as shown), the effluent total phosphorus discharge standard is 0.5mg / L. An electromagnetic flowmeter 61 is set at the water inlet of the biological treatment unit 1 , an online phosphate meter 62 is set at the water outlet of the secondary sedimentation tank 2 , and an effluent total phosphorus meter 63 is set at the water outlet of the advanced treatment unit 3 . Add a chemical phosphorus removal control cabinet near the dosing pump for phosphorus removal agents, and configure industrial computers, PLCs, frequency converters for dosing pumps, etc. Instrument signals such as phosphate effluent, effluent total phosphorus, and influent flow ...

Embodiment 2

[0067] On the basis of Example 1, this example adopts the post-position phosphorus removal process, and changes the dosing point to figure 1 As shown in ② position, instrument configuration and other device settings remain unchanged. The phosphate control of the effluent of the secondary sedimentation tank adopts the feed-forward proportional algorithm, and the dosing flow ΔQ is calculated according to formulas (3) and (5) 1 , the parameter K in formula (5) 3 and K 4 The initial values are 2 and 0.5, which are further determined to be 5 and 0.6 through on-site debugging experiments. Feedforward water compensation control dosing amount ΔQ 2 and effluent total phosphorus safety margin feedback compensation dosing amount ΔQ 3 The calculation process is the same as the first embodiment.

[0068] Through trial operation, the total phosphorus in the effluent reaches the standard stably, and compared with constant dosing, the dosage is reduced by more than 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com