An automatic leveling mechanism of an arch bridge inspection vehicle

An automatic leveling and arch bridge technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems such as unfavorable detection, threat to the life safety of inspectors, and large demand for arch bridge inspection, so as to achieve the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

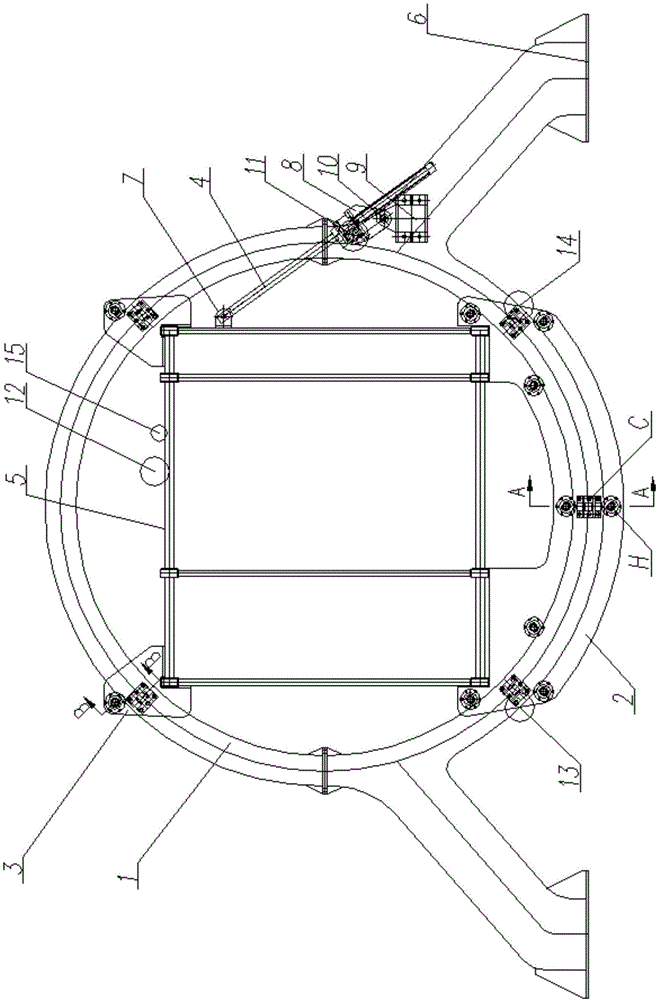

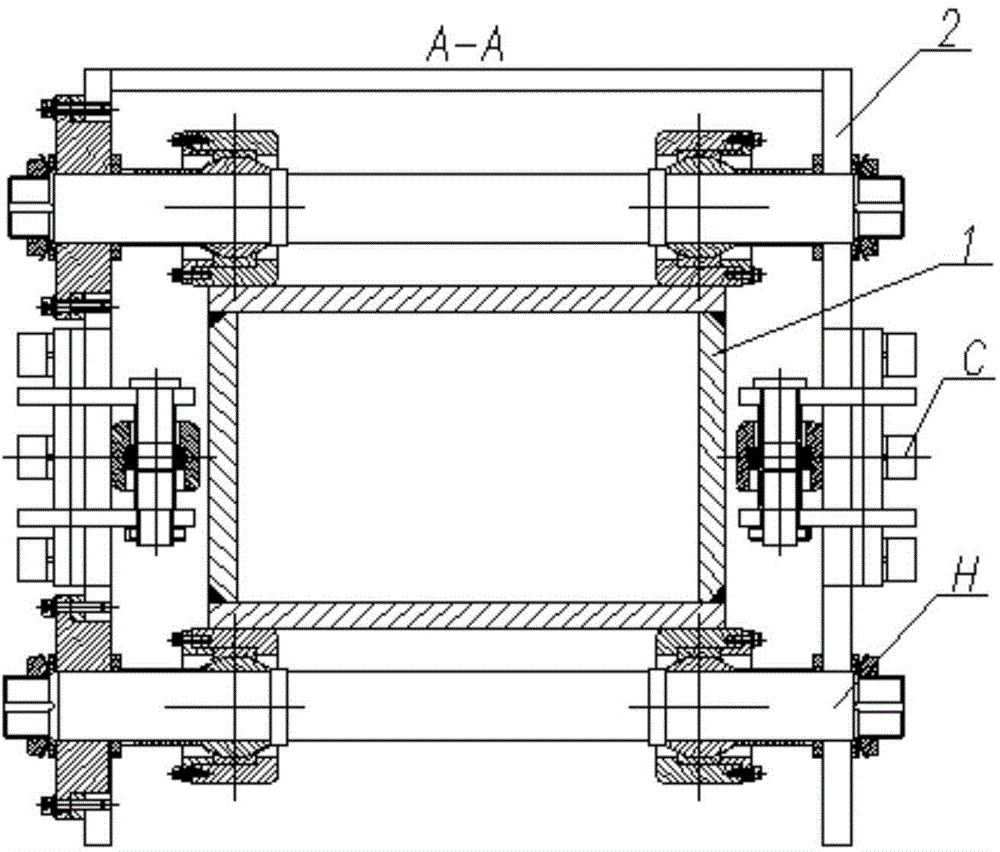

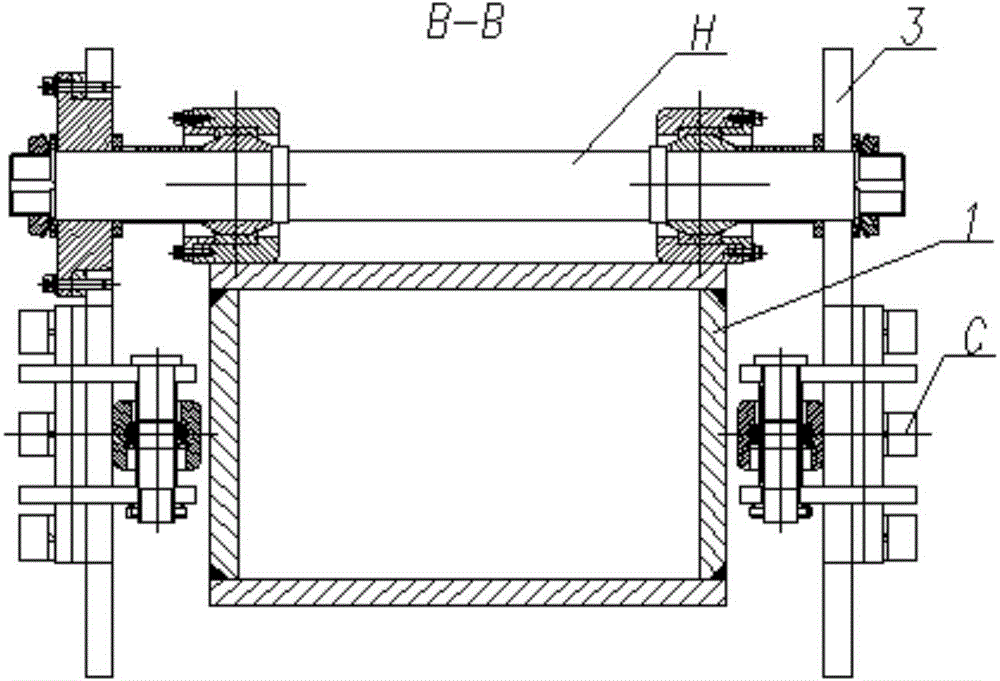

[0016] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

[0017] The automatic leveling mechanism of the bridge inspection vehicle of the present invention includes an inspection vehicle frame, a worm gear lifting mechanism, a leveling connecting frame and a control system. The leveling connecting frame is composed of a ring main frame, a lower connecting frame, an upper connecting frame and a guide wheel. Composed in groups, the guide wheel assembly group is composed of the ring main frame 1 torus guide wheel assembly H and the side guide wheel assembly C, the lower connecting frame 2 symmetrical ring main frame 1 center line is set on the ring main frame 1 The lower connecting frame 2 is respectively connected with the inner and outer ring surfaces and both sides of the lower part of the ring main frame 1 through the guide wheel assembly set at the bottom of the ring main frame 1 at corresponding intervals, and the rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com