Deformation monitoring equipment, deformation monitoring method and granary deformation monitoring system

A technology for monitoring equipment and deformation, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of high cost and low degree of automation of deformation monitoring, and achieve the effects of low cost, avoiding fire safety hazards, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

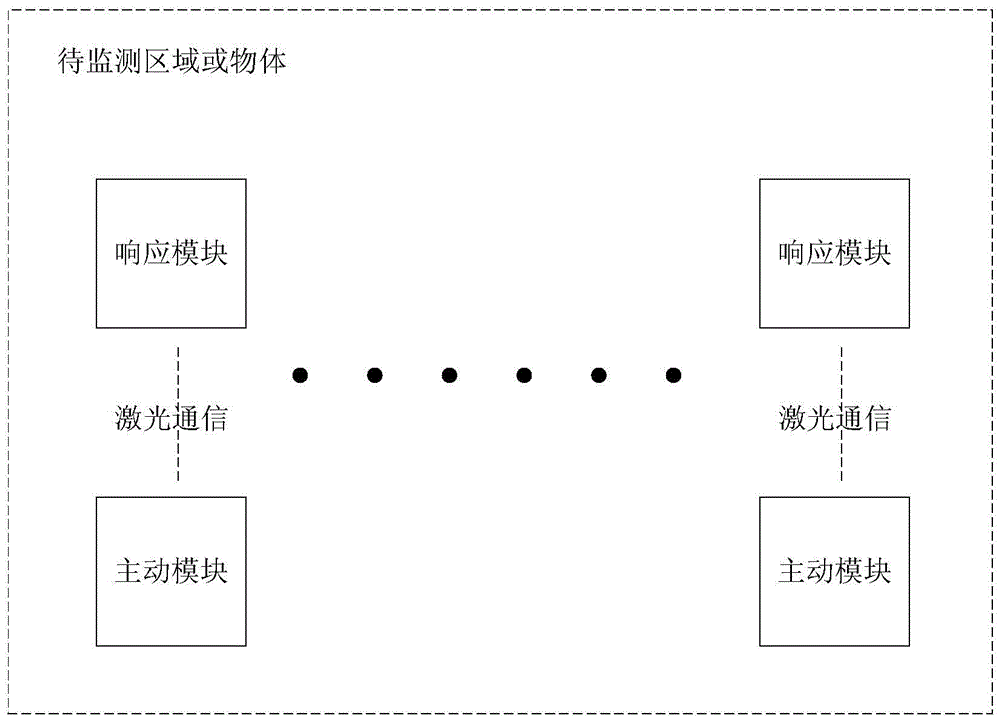

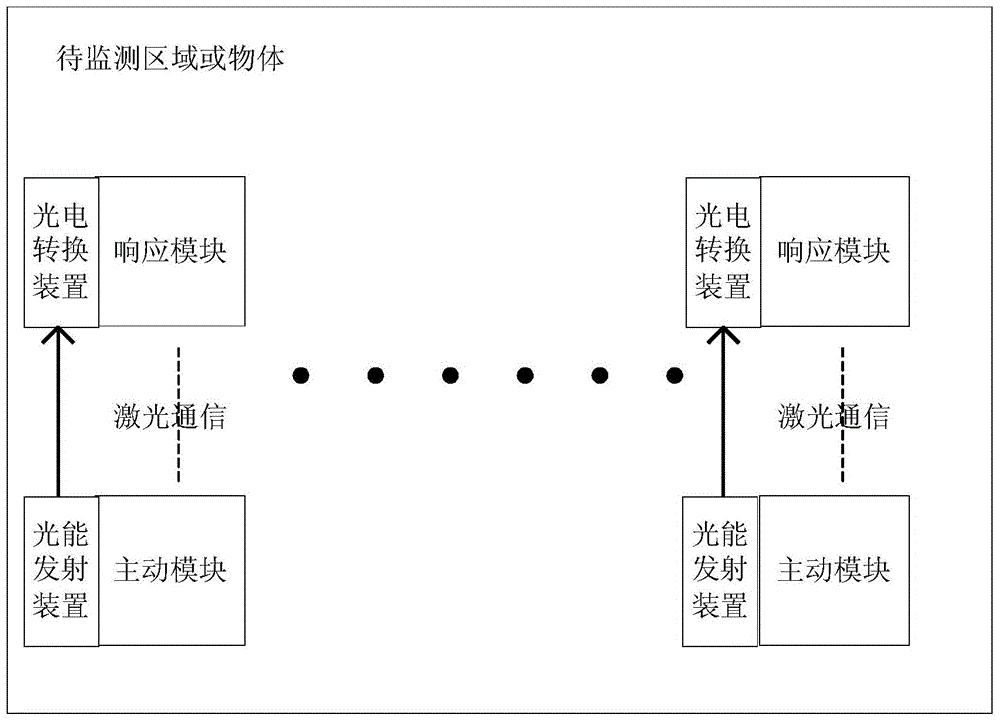

[0031] Such as figure 1 A deformation monitoring system is shown, and its equipment is arranged on the area or object to be monitored. The equipment mainly includes at least one set of laser communication devices. Each set of laser communication devices is composed of an active module and a corresponding response module. The active module Both the response module and the laser are provided with a laser for emitting laser signals and a photoelectric converter for receiving laser signals.

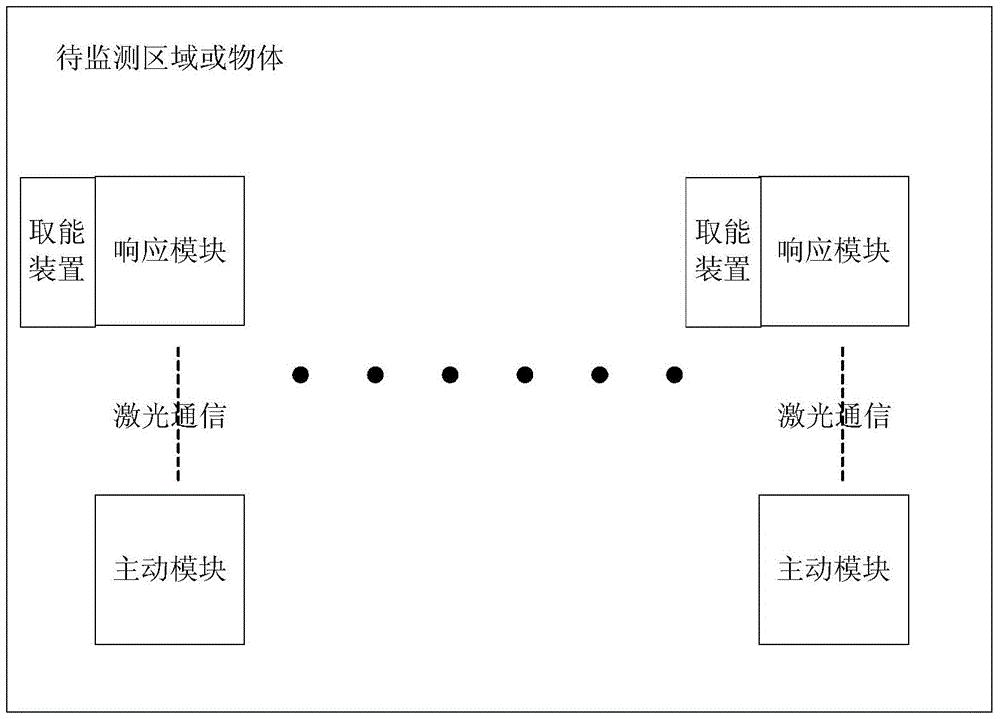

[0032] In order to minimize the laying of cable lines, both the active module and the response module can be powered by non-power supply lines, such as taking power from the environment, such as solar energy, vibration energy, etc. For cost considerations, the active module can be powered by a power supply line and placed in a location where wiring is easy, while the respon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com