Seal structure of vanadium battery

A sealed structure, vanadium battery technology, applied in the field of vanadium batteries, can solve the problems of discharge, positive and negative liquid mixing, spring 4 deformation, etc., to avoid mutual leakage and improve the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing.

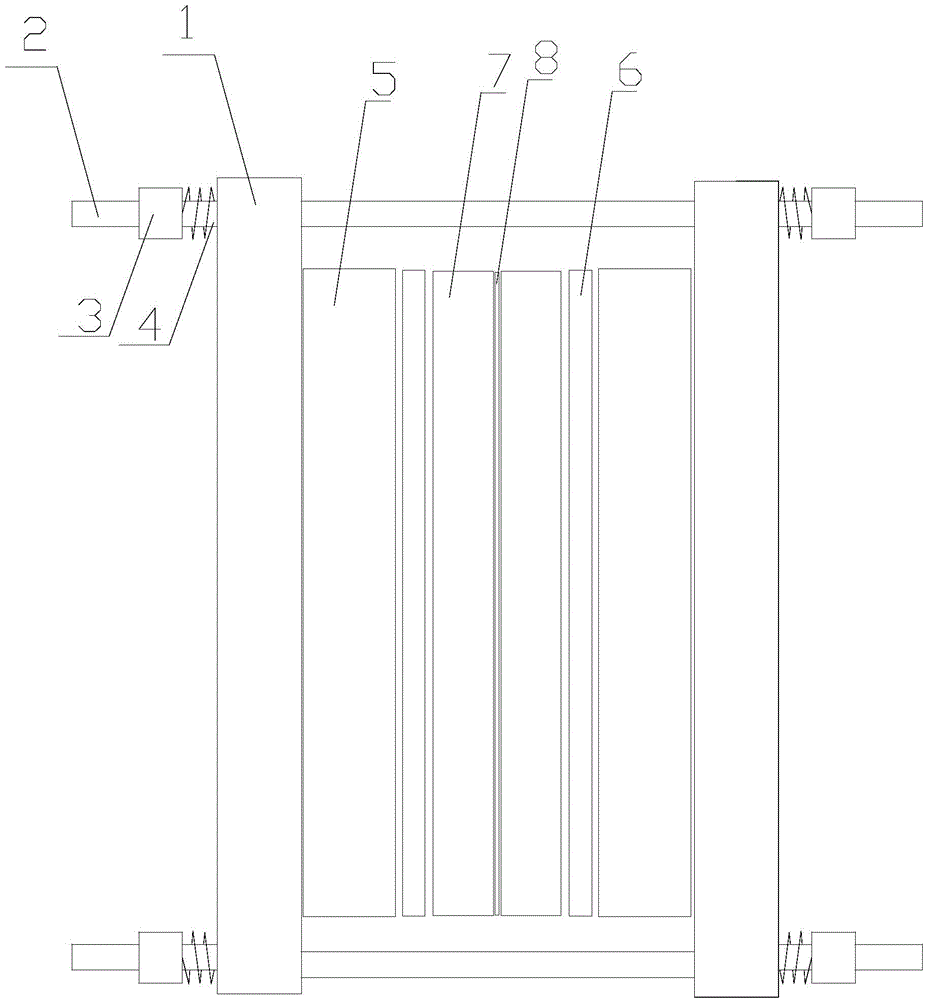

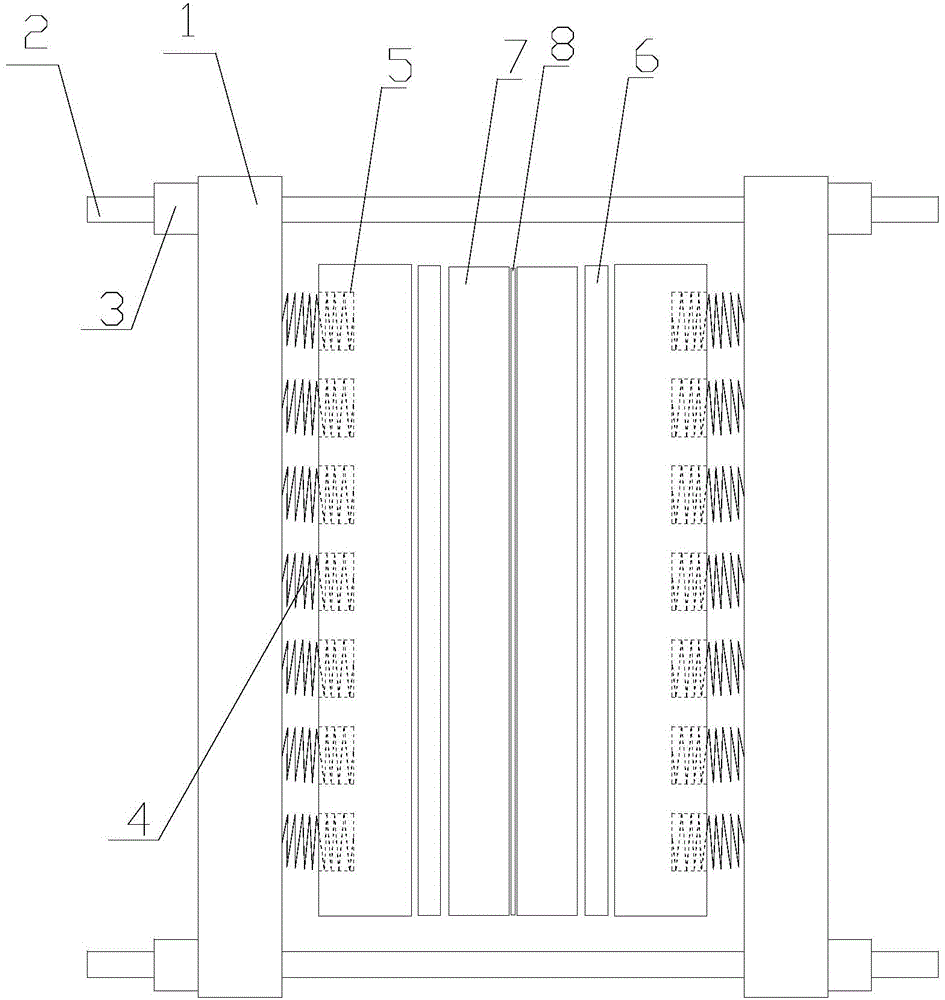

[0020] see figure 2 with image 3 , the invention includes a steel structure splint, a screw rod, a nut, a runner side plate and a spring. One side of the runner side plate 5 is provided with a spring fixing structure, one end of the spring 4 is installed in the spring fixing structure, the other end of the spring 4 is in contact with one side of the steel structure splint 1, and the nut 3 is sleeved on the screw rod 2, The nut 3 is in contact with the other side of the steel structure splint 1 .

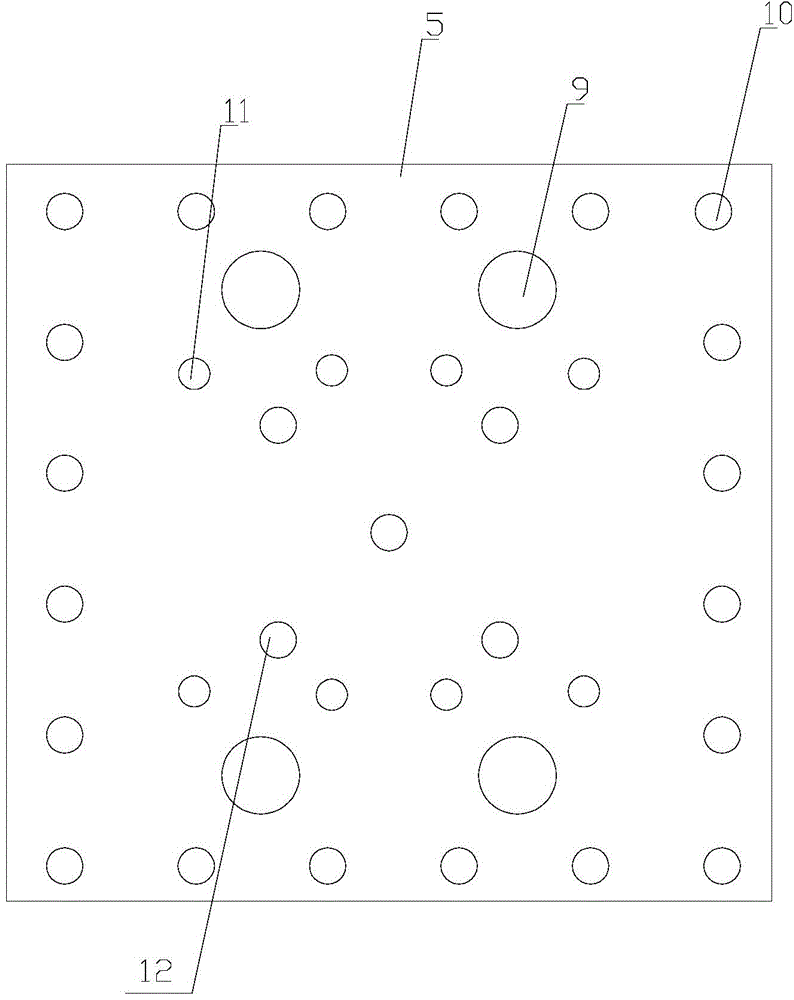

[0021] In the present invention, the spring fixing structure includes an outer ring spring fixing structure 10 , an inner ring spring fixing structure 11 and a central spring fixing structure 12 .

[0022] The outer ring spring fixing structures 10 are respectively arranged on the outer ring frame of the flow channel side plate 5, and the distance between every two outer ring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com