Equipment for producing fiber products by laying down melt-spun fibers

A technology of fiber products and equipment, which is applied in the field of equipment for producing fiber products, can solve the problems that individual displacement/adjustment of suction chambers and holes can not be realized, and achieve the effect of expanding flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

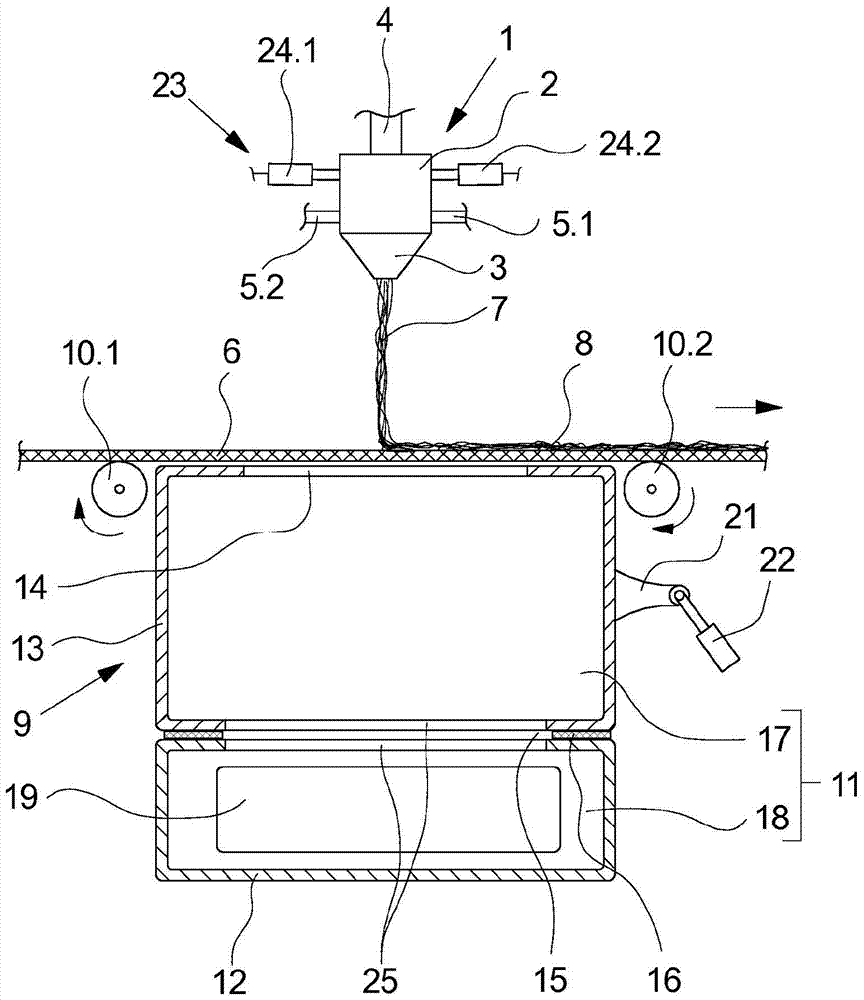

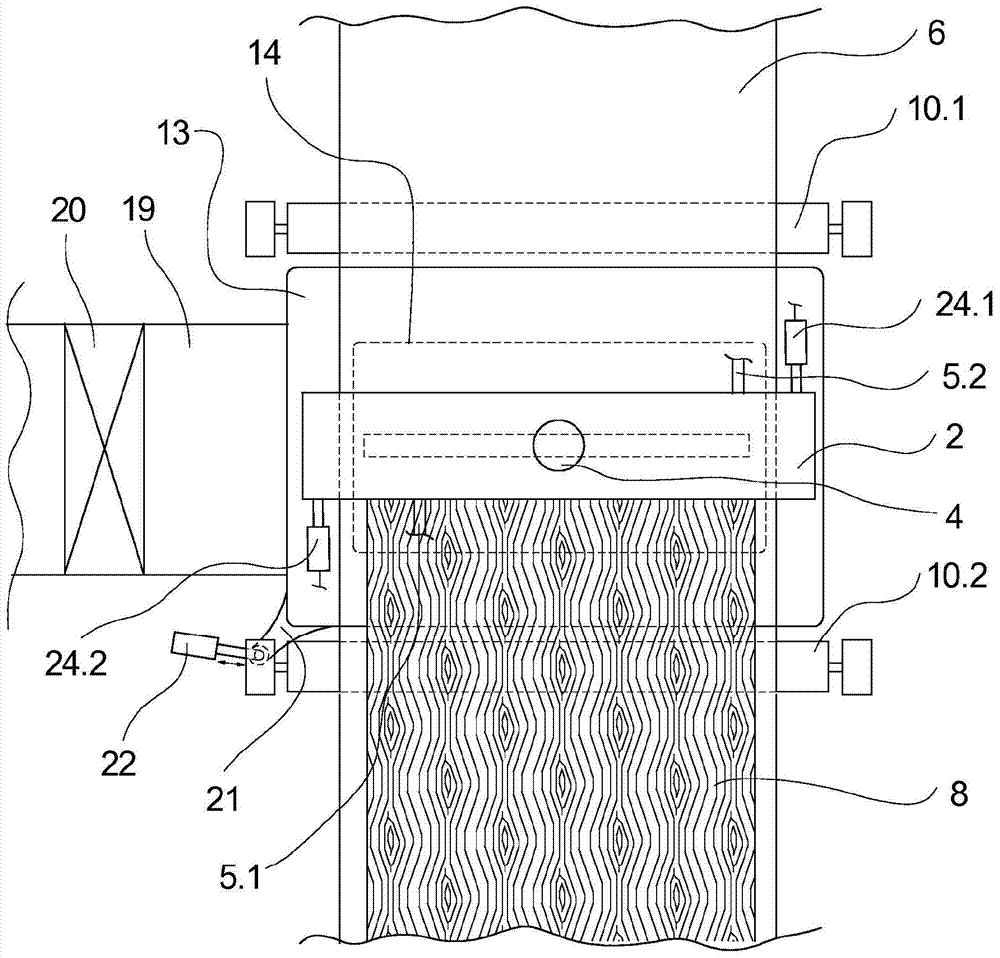

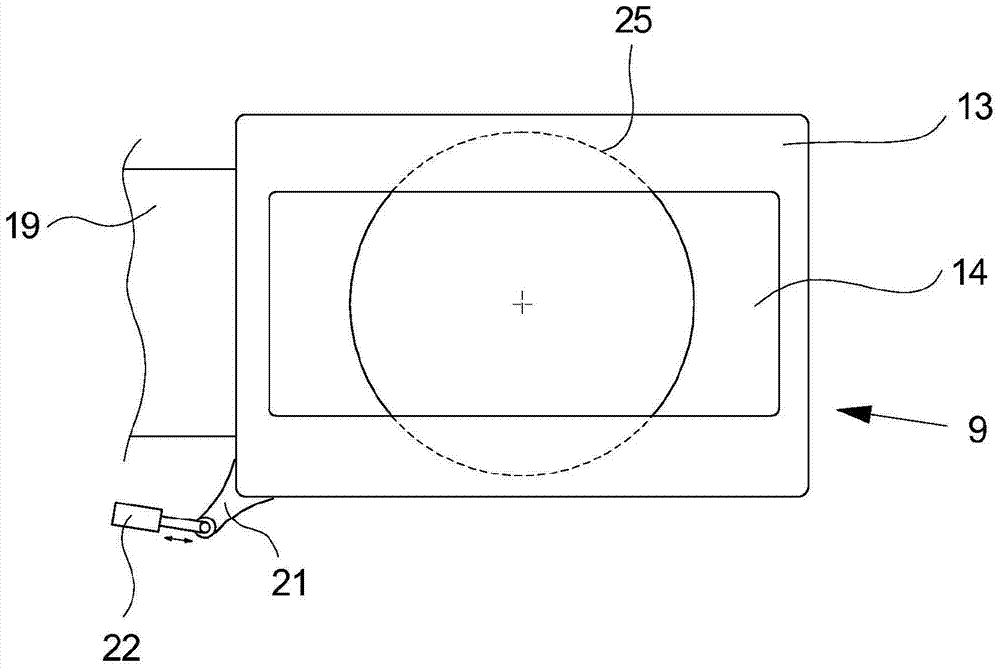

[0028] exist figure 1 and 2 A first embodiment is shown schematically in several views in . figure 1 A longitudinal sectional view of this embodiment is shown, figure 2 A top view is shown. The following description applies to both figures, as long as reference is not explicitly made to a certain figure.

[0029] A first embodiment of the device according to the invention for producing fiber products by depositing melt-spun fibers has an air-permeable deposit belt 6 which is guided over a plurality of belt rollers 10.1 and 10.2. The deposit belt 6 is only partially shown and is generally designed as an endless belt and is guided by one or more driven belt rollers.

[0030] On the upper side of the deposit belt 6 there is a spinning device 1 comprising a spinning beam 2 arranged at a distance from the deposit belt 6 . The spin beam 2 has on its underside a nozzle arrangement 3 which in this case serves to melt blow the fibers out of the spinning nozzle and which has two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com