Synchronous belt drive flexible presser foot temperature control cloth perforating positioning machine

A synchronous belt transmission and synchronous belt technology, applied in cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of low measurement accuracy, low efficiency, cumbersome work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing the specific embodiment of the present invention is described in further detail.

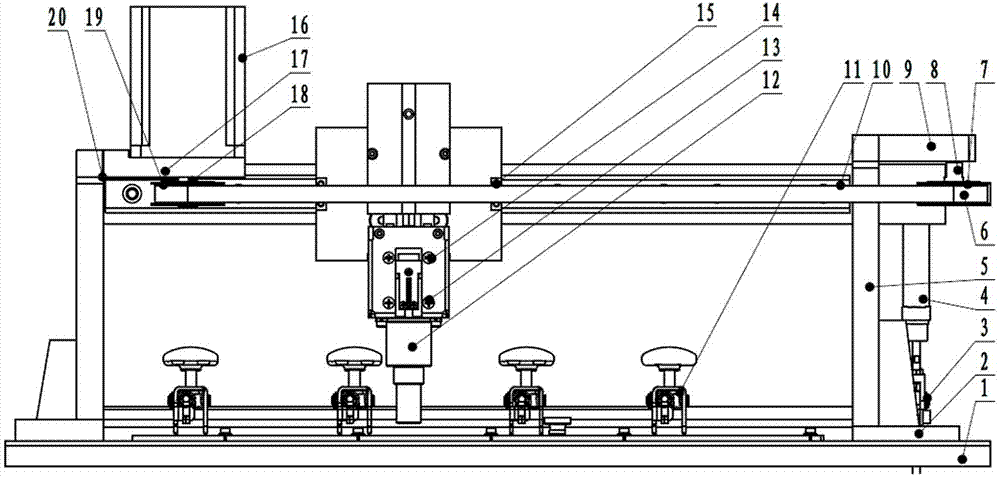

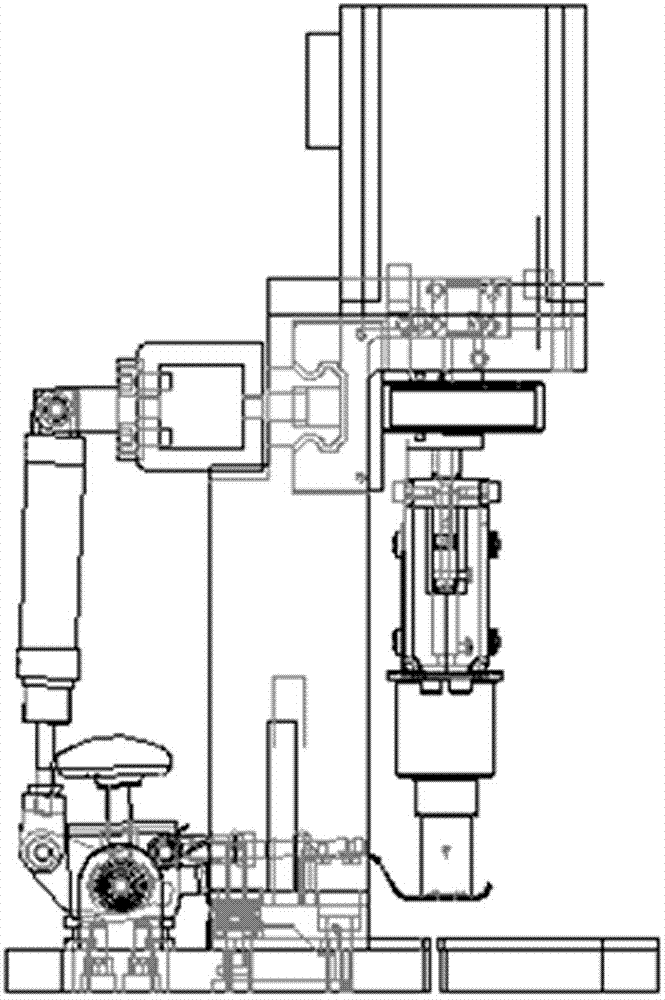

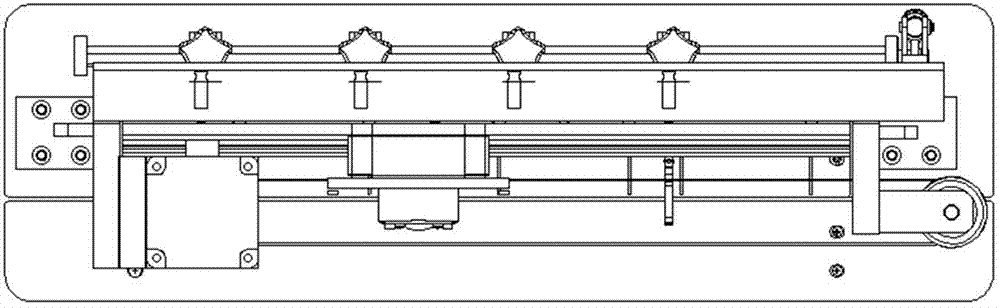

[0020] like Figure 1-3 As shown, the synchronous belt-driven flexible presser foot temperature-controlled cloth perforation positioning machine of the present invention includes a rotary pressing mechanism for clothing, a synchronous belt transmission mechanism for buttonhole / keyhole perforation mechanisms, a perforation mechanism, and temperature-controlled heating for perforation and setting. Institutional and operational control systems.

[0021] The rotary pressing mechanism is composed of a base plate 1, a fixed support 2, a rocker link assembly 3, a telescopic cylinder 4, and a support column 5; 8. Tension mechanism 9, active synchronous wheel 19, ball screw guide rail 10, slider group, auxiliary synchronous wheel, perforation and compression mechanism 12, synchronous belt pressure plate mechanism 15, drive motor 16, drive motor mount...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap