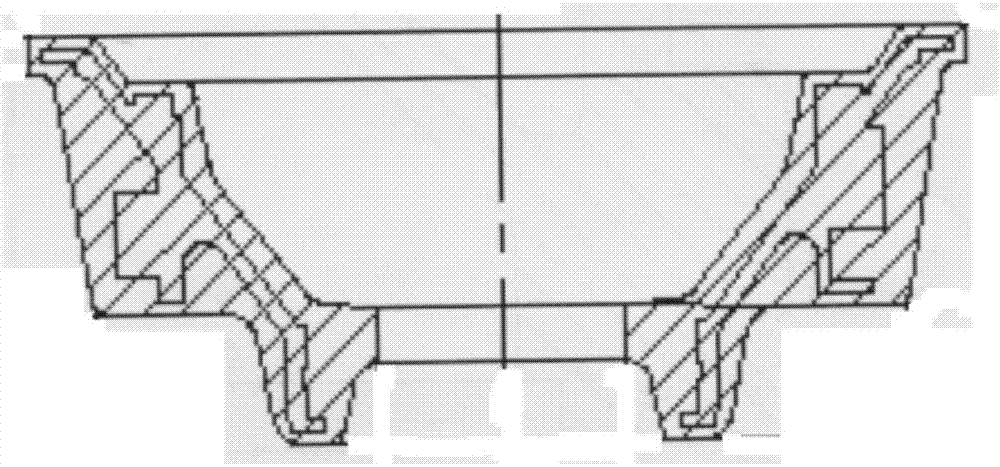

Method for machining bearing block parts with precision dimensions

A process method and bearing seat technology are applied in the field of precision dimension processing of bearing seat parts, which can solve the problems of precision dimension deformation of bearing seat parts, and achieve the effect of wide prospect and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

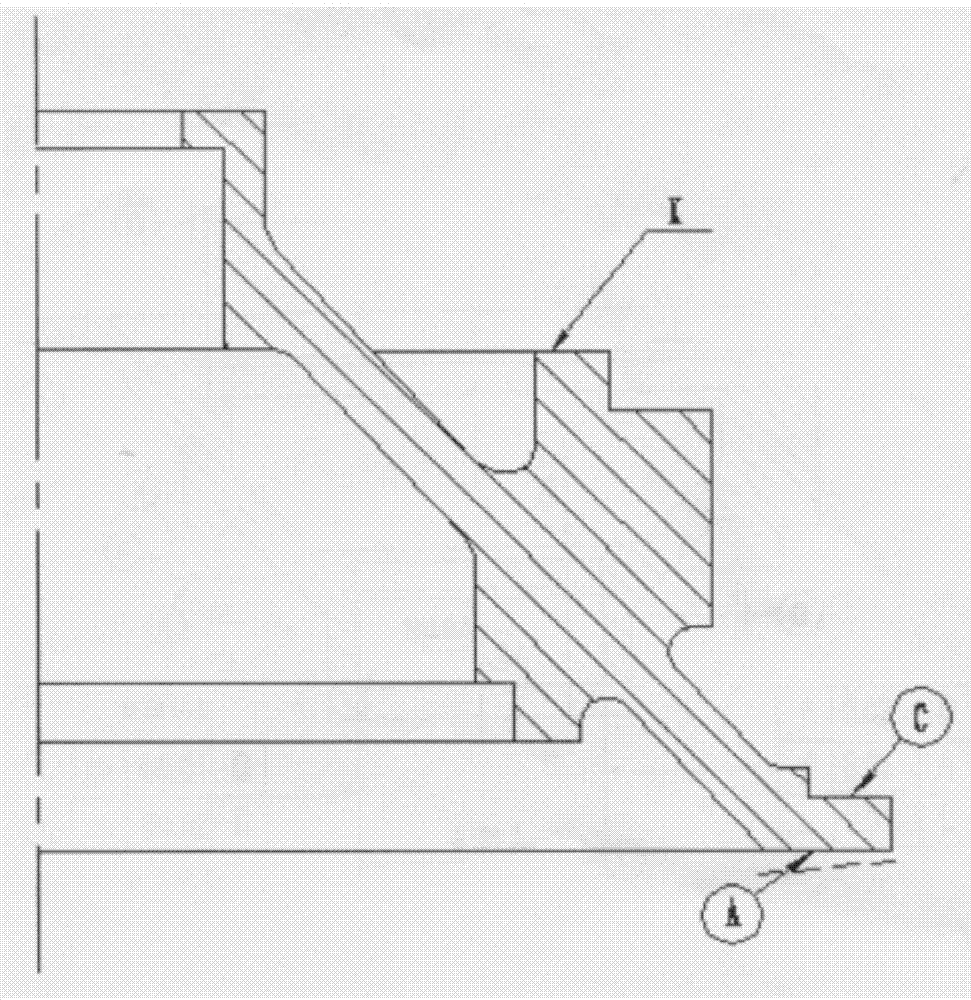

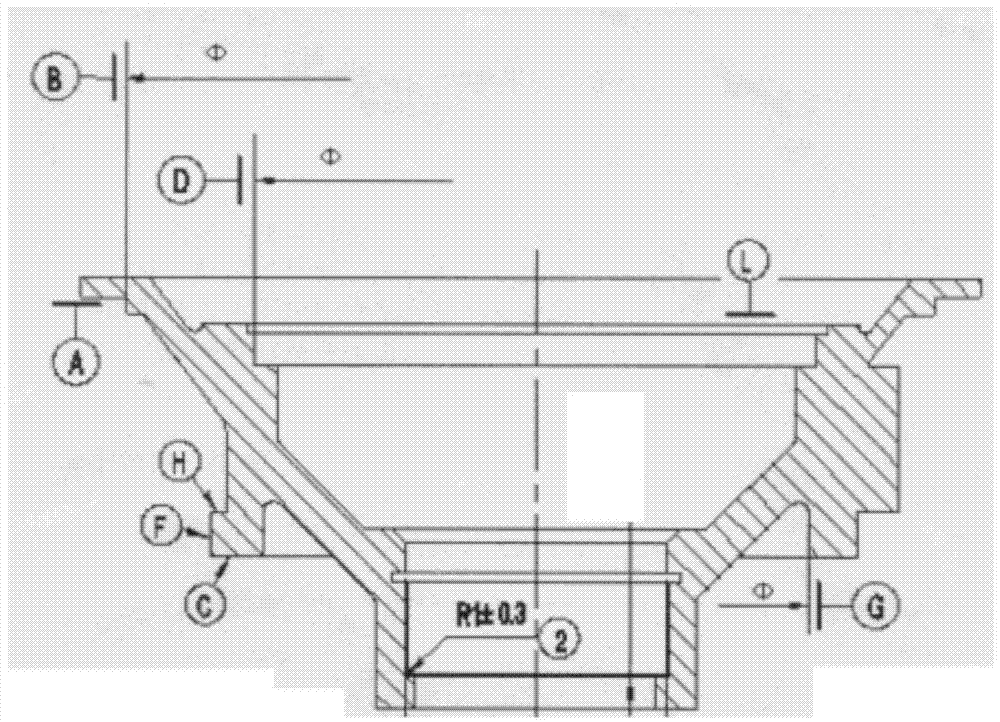

Embodiment 1

[0022] The present invention provides a processing method for precision dimensioning of bearing seat parts, which is characterized in that: in the process for processing the precise dimensioning of bearing seat parts, a separate finishing process of important diameter dimensions is added after all machining processes are completed; from The flatness of the reference plane of the part, the flatness of the faceplate of the machine tool, and the flatness of the positioning surface of the fixture are controlled in three aspects, and the coloring and closeness of the reference surface of the part is strengthened to strengthen the process control; the faceplate and the fixture surface of the machine tool are trimmed to ensure that the flatness of the positioning surface of the fixture is 0.005max, and the parts The bonding degree between the processing datum surface and the positioning surface of the fixture is more than 75% (using the method of coloring inspection), and there is no s...

Embodiment 2

[0034]The present invention provides a processing method for precision dimensioning of bearing seat parts, which is characterized in that: in the process for processing the precise dimensioning of bearing seat parts, a separate finishing process of important diameter dimensions is added after all machining processes are completed; from The flatness of the reference plane of the part, the flatness of the faceplate of the machine tool, and the flatness of the positioning surface of the fixture are controlled in three aspects, and the coloring and closeness of the reference surface of the part is strengthened to strengthen the process control; the faceplate and the fixture surface of the machine tool are trimmed to ensure that the flatness of the positioning surface of the fixture is 0.005max, and the parts The bonding degree between the processing datum surface and the positioning surface of the fixture is more than 75% (using the method of coloring inspection), and there is no su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap