High-voltage static drive and variable-diameter 3D (three dimensional) printer

A 3D printer, high-voltage electrostatic technology, applied in the field of 3D printing, can solve problems such as limited types, achieve the effect of improving product quality and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

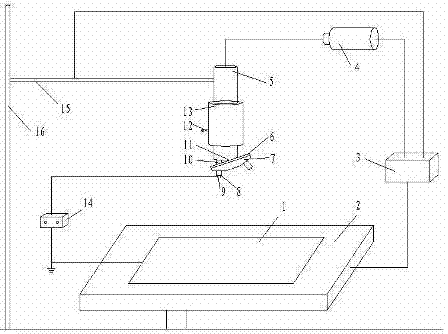

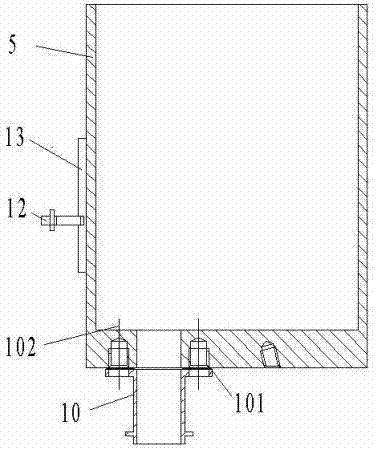

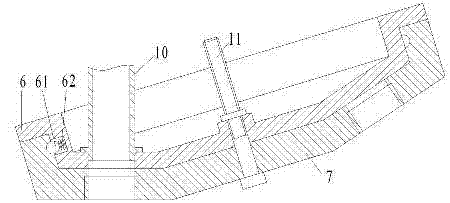

[0019] This patent is a high-voltage electrostatically driven and variable-diameter 3D printer, which includes a receiving device (1), a mobile platform (2), a computer (3), a precision micro-injection pump (4), a high-voltage electrostatic generator (14), a vertical Straight guide rail (16), horizontal rod (15) and 3D printing nozzle. The 3D printing nozzle mainly consists of a barrel (5), a heating ring (13) and a thermocouple (12) wrapped outside the barrel (5), the lower end It consists of a cylindrical flow channel (10) with a protruding outer edge, a converter composed of a fixed ring (6) and a rotating ring (7), a nozzle (8) and a needle (9). There is a gasket (101) between the cylindrical flow channel (10) and the barrel (5), and the three are connected by screws (102). The fixed ring (6) with the threaded through hole and the rotating ring (7) with a light hole at the bottom are connected by bolts (11) and connected to the bottom of the barrel (5) for fixing. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com