A multi-functional full-size tobacco leaf automatic packing complete set device

A complete set of device and multi-functional technology, applied in the fields of packaging machinery and tobacco leaf packaging machinery, can solve the problems of unfavorable storage, transportation, low efficiency of manual packaging, and high production cost, and achieve a low production cost, simple structure and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or improvements based on the teaching of the present invention fall within the scope of protection of the present invention.

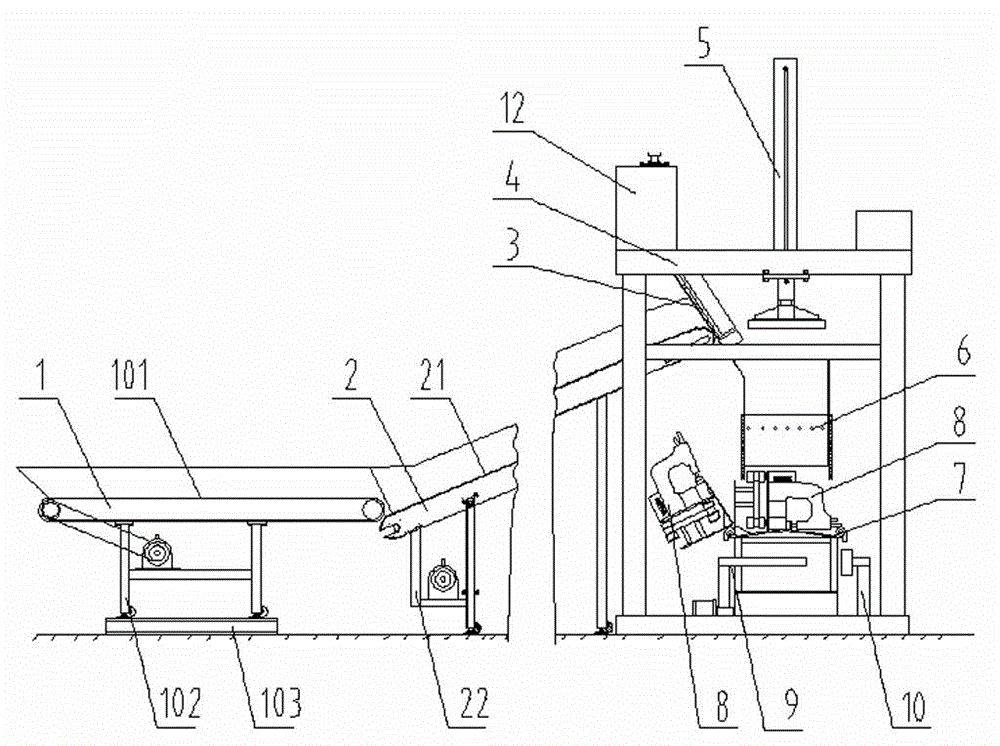

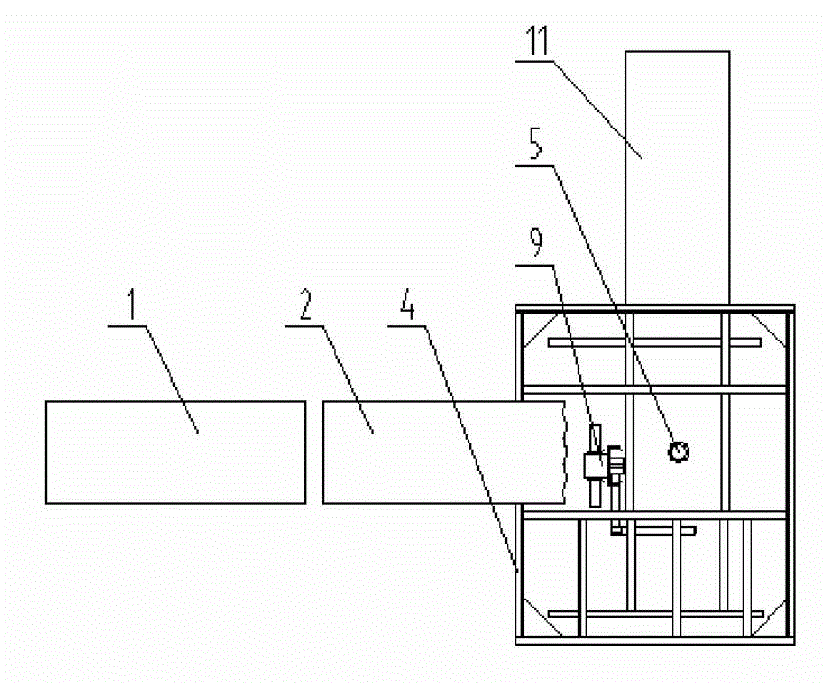

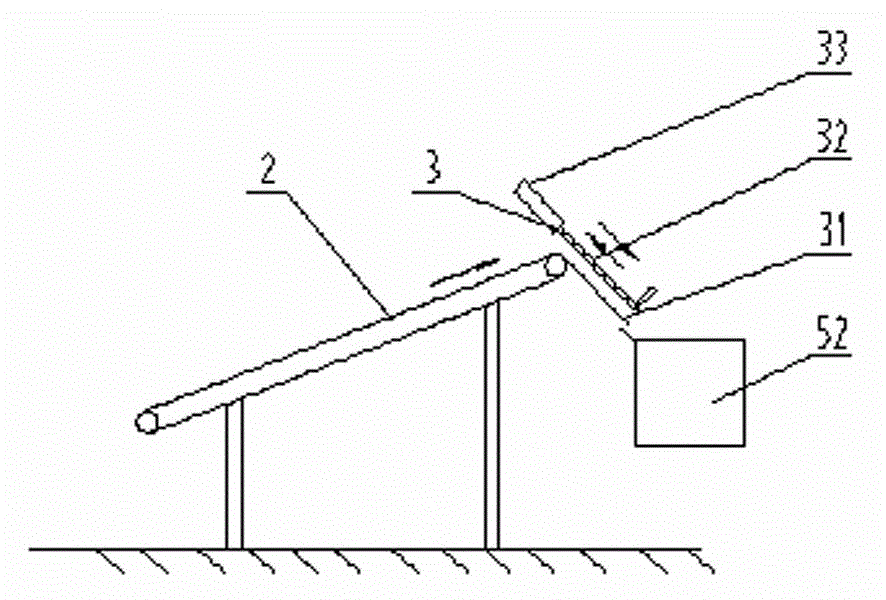

[0018] like Figure 1-10 As shown, the present invention includes a metering belt conveyor 1, a feeding belt conveyor 2, a packing and equalizing device 3, a frame 4, a cigarette packet forming device 5, a packaging bag opening device 6, a folding device 7, Pocket opening automatic seaming device 8, cigarette pack automatic on-line conveying device 9, basic information automatic labeling device 10, finished product output belt conveyor 11, hydraulic system 12, the above-mentioned feeding belt conveyor 2 is set on the metering belt Between the type conveyor 1 and the frame 4, a packaging and equalizing device 3 is provided at the discharge end; a hydraulic system 12 is provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com