Spring machine automatic feeding device

An automatic feeding and spring machine technology, applied in the direction of thin material handling, transportation and packaging, and conveying filamentous materials, etc., can solve the problems of uneven strength, wire damage, wire deformation, etc., to ensure the quality of feeding and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with accompanying drawing:

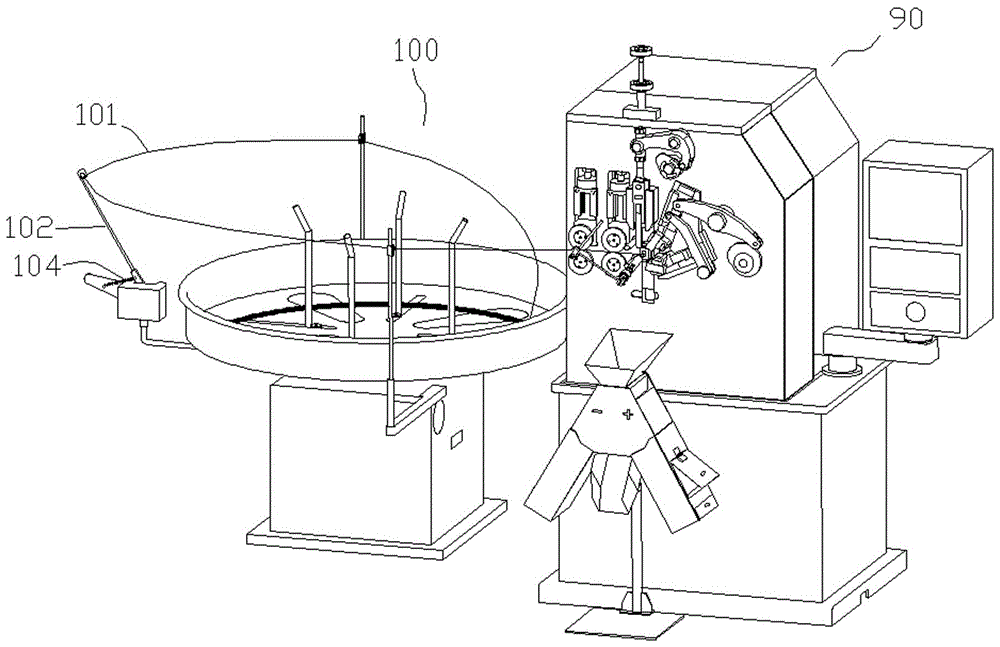

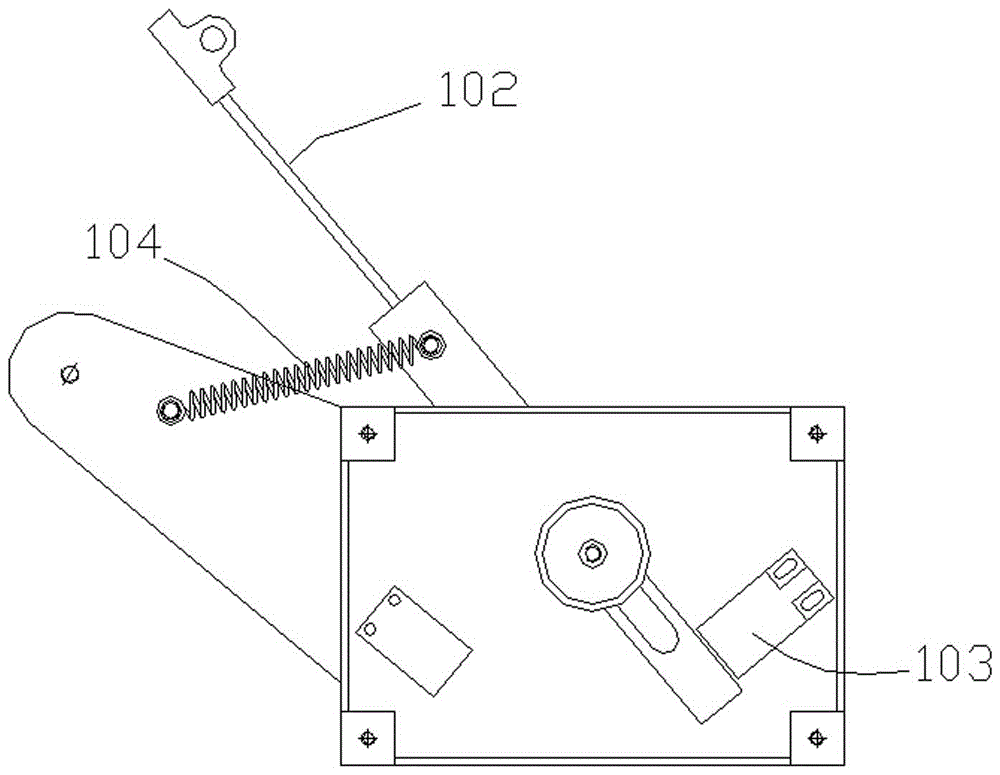

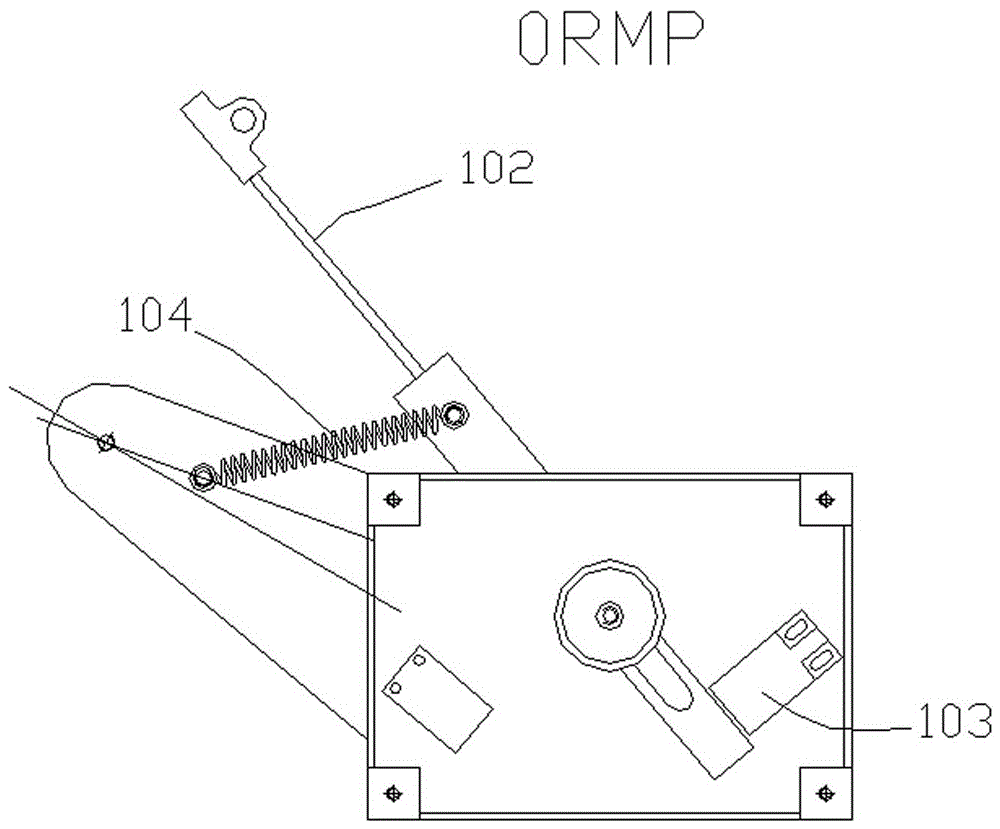

[0032] refer to Figure 4~11 As shown, the present invention relates to an automatic feeding device for a spring machine, which includes a pull rod reset constant force mechanism, a feeding acceleration and deceleration mechanism, and an alarm safety mechanism, wherein: the pull rod reset constant force mechanism is a certain pulley mechanism with a certain pulley 1. A scale hammer 3 is suspended on the fixed pulley 1, and the scale hammer 3 is suspended on the fixed pulley 1 through a winding wire; the axis of the fixed pulley 1 is fixedly connected with the pull rod 2, and the other extended end of the pull rod 2 has a spring wire for passing through. The thread hole 21 of setting, the moment of gravity of the gravity of scale hammer 3 relative to the axle center of fixed pulley 1 is equal to the moment of pull bar stressed relative to the axle center of fixed pulley 1, realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com