A four-leg synchronous hydraulic lifting mechanism

A hydraulic lifting and supporting foot technology, which is applied in the direction of lifting frame and lifting device, can solve the problems of small distance from the ground, cannot meet the requirements of disassembly and assembly of the main landing gear, complex structure, etc., and achieve the effect of simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

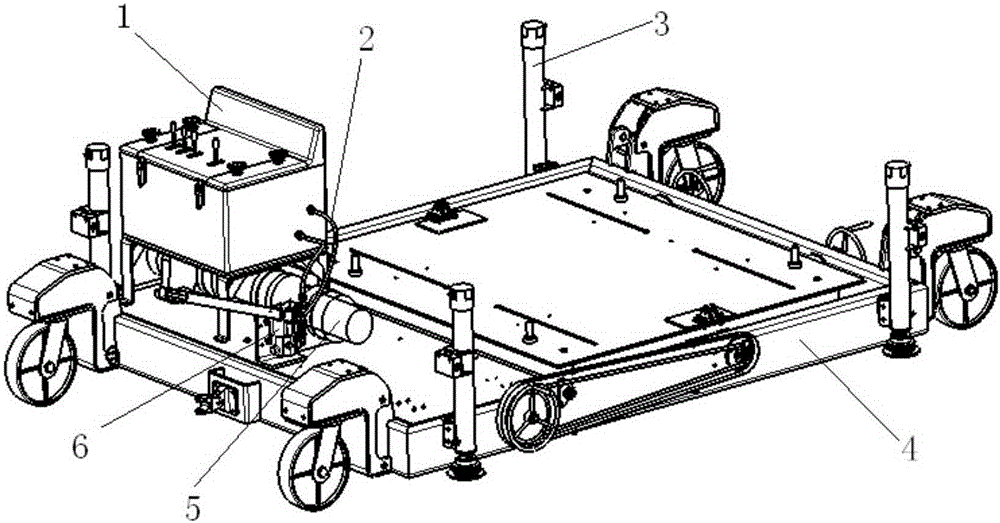

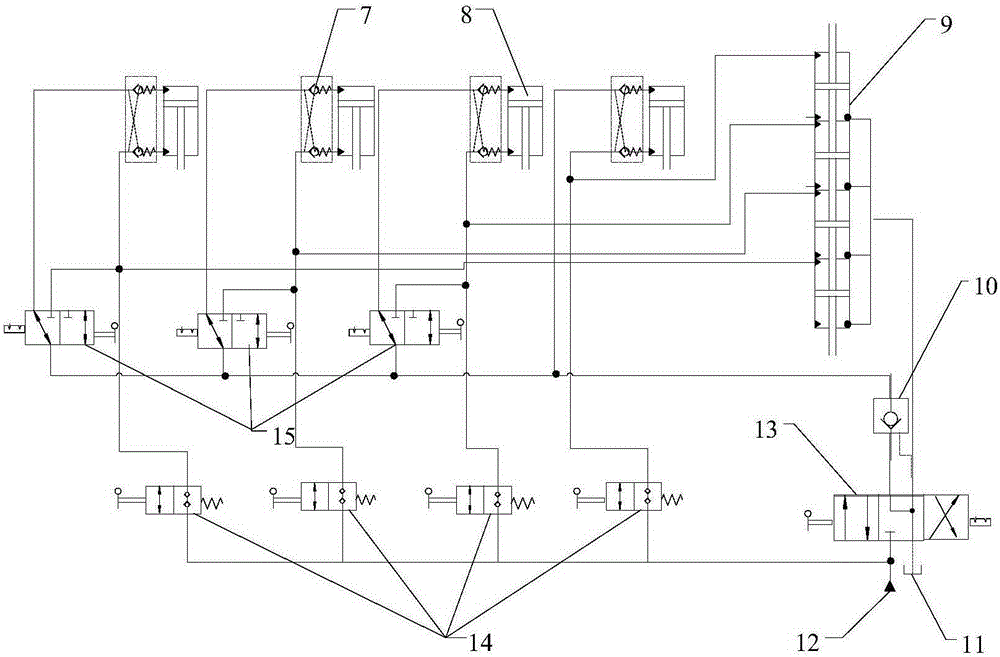

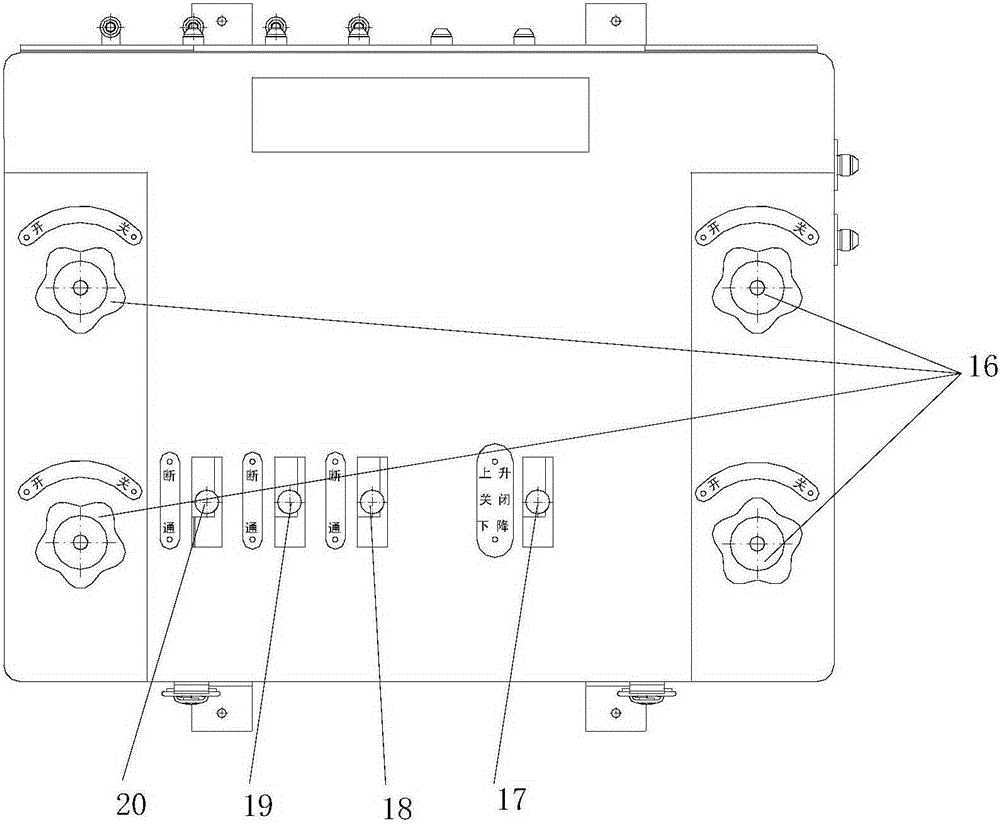

[0019] see figure 1 , figure 2 , a specific embodiment of the present invention mainly includes a hydraulic control box 1, combined conduit 2, hydraulic support feet 3 / 8, car body 4, synchronous cylinder 5 / 9, hand pump 6 / 12, two-way hydraulic lock 7, hydraulic control Check valve 10, fuel tank 11, three-position four-way valve 13, screw switch 14 / 16, two-position three-way valve 15, handle I17, handle IV18, handle III19, handle II20. Among them, the hydraulic control box 1, four hydraulic feet 3, the synchronous cylinder 5 and the hand pump 6 form the lifting mechanism. The main body is installed on the car body 4 of the installation vehicle, and four two-way hydraulic locks 7 are respectively installed on the oil inlet and outlet of each hydraulic foot. , hydraulic control check valve 10, oil tank 11, three-position four-way valve 13, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com