Ultra-short fiber spinning method and device

A technology of ultra-short fiber and winding device, which is applied in the direction of spinning machine, textile and papermaking, drafting equipment, etc., and can solve the problem of low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

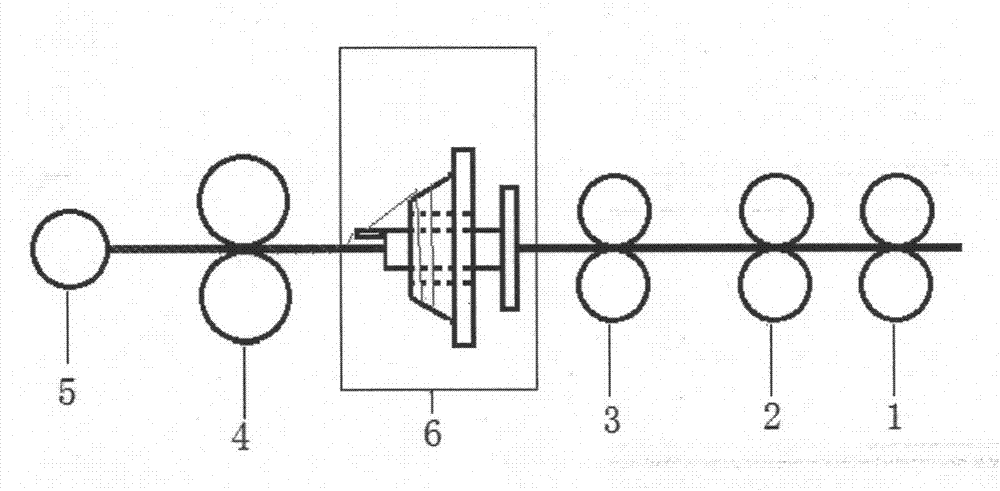

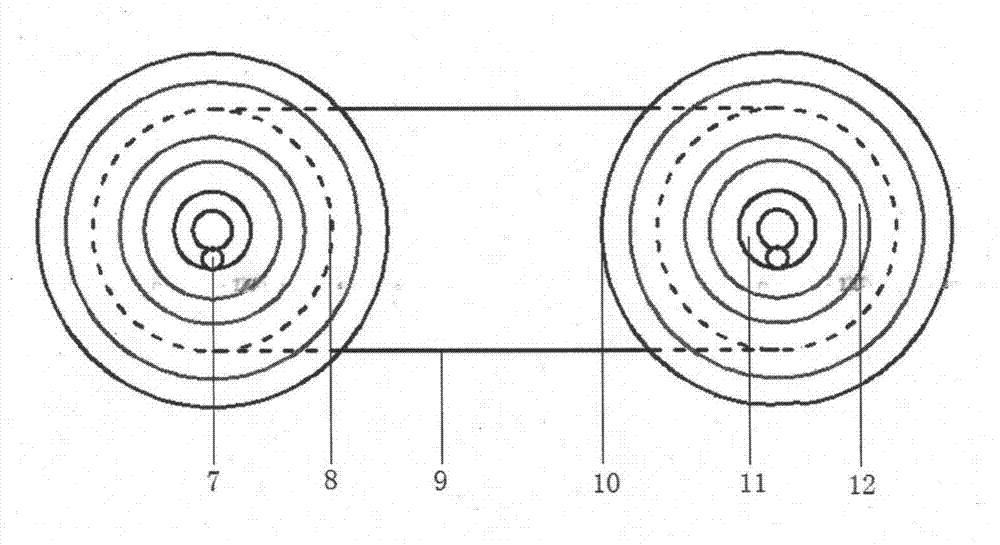

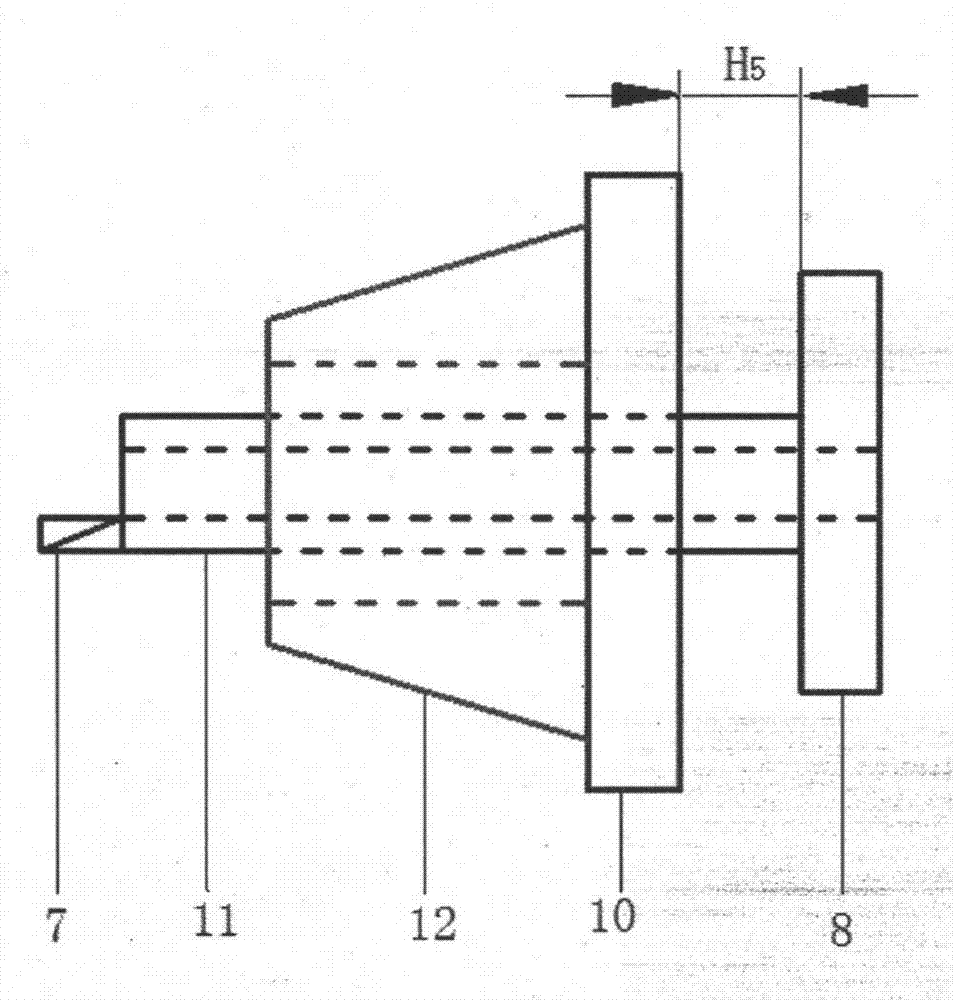

[0027] A kind of ultra-short fiber spinning device, such as figure 1 As shown, it comprises front roller 3, middle roller 2, back roller 1, output roller 4, annular winding device 6, spinning frame twisting mechanism 5, and annular winding device 6 consists of filament package 12, tension device 7, The filament package fixing mechanism 10, the filament winding shaft 11, the winding shaft transmission mechanism 8 and the winding shaft transmission belt 9 are composed. The front roller 3, the middle roller 2, and the rear roller 1 are all a pair and are arranged sequentially from front to back, and the front roller 3 front is successively equipped with an annular winding device 6 and a pair of output rollers 4. Such as figure 2 , image 3 As shown, the annular winding device 6 includes three parts: the first part is a filament winding device, which is composed of a filament winding shaft 11, a winding shaft transmission mechanism 8 and a winding shaft transmission belt 9, and...

Embodiment 2

[0036] The draft ratio in the region between the delivery roller 4 and the front roller 3 of the present invention is 0.99. The filament winding shaft 11 of the filament winding device has a hollow structure with a thickness of 7 mm, an inner diameter D1 of 8 mm, an outer diameter D2 of 15 mm, and a length H1 of 110 mm. One end of the filament winding shaft 11 is installed on the winding shaft transmission mechanism 8, and the other end of the filament winding shaft 11 passes through the filament package fixing mechanism 10 and the filament package 12 in turn, and is fixed with the tension device 7 connect. The winding shaft transmission mechanism 8 is a bearing structure, and the winding shaft transmission mechanism 8 is fixed on the spinning machine body through its bearing inner ring, and its bearing outer ring is used to fix the filament winding shaft 11, and the winding shaft transmission mechanism 8 The bearing width H2 is 15mm, and the winding shaft transmission mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com