A wrap-type concentrated spinning method and device thereof

A wrapping and winding device technology, applied in the directions of yarn, textile and papermaking, can solve the problems of poor wrapping effect of short fiber noil, low yarn strength, low reuse rate of short fiber noil, etc. The effect of improving the utilization rate of noil and enriching the variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

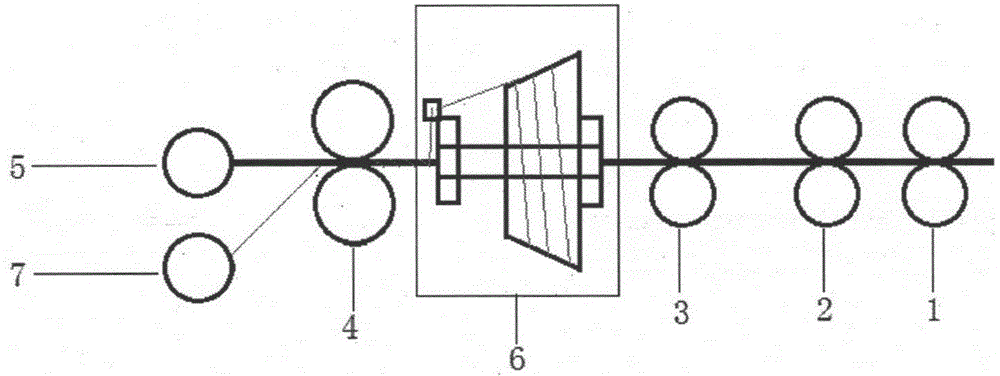

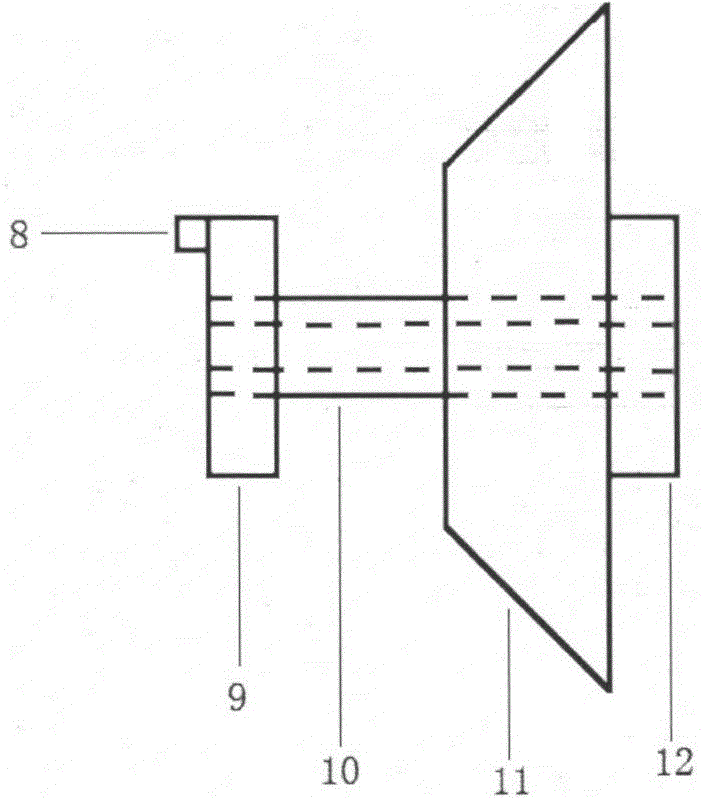

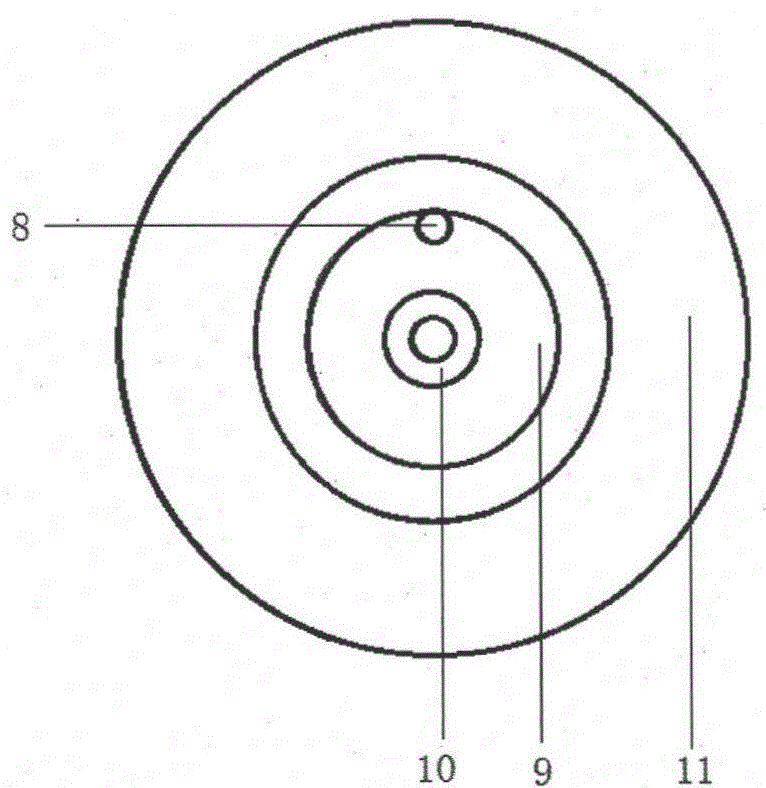

[0027] A covered compact spinning device, such as figure 1 As shown, it includes front roller 3, middle roller 2, rear roller 1, spinning frame twisting mechanism 5, output roller 4, annular winding device 6, filament unwinding device 7, front roller 3, middle roller 2, rear roller The rollers 1 are arranged in sequence from front to back, and a special annular winding device 6 is installed between the front roller 3 and the output roller 4. Such as diagram 2-1 , Figure 2-2 As shown, the annular winding device 6 includes three parts: the first part is the hollow fixed shaft 10; the second part is the filament package mechanism, which is fixed by the filament package 11 and the filament package installed on the hollow fixed shaft 10 The machine part 12 is composed; the third part is a winding mechanism, which is composed of a filament winding machine part 9 and a tension device 8 installed on a hollow fixed shaft. Such as Figure 4 As shown, the filament winding mechanism...

Embodiment 2

[0036] The draft ratio between the output roller 4 and the front roller 3 is 0.99; the hollow fixed shaft 10 is installed between the front roller and the output roller, and is fixed on the spinning frame for passing short fiber strands. Its outer diameter D1 is 15mm, the inner diameter D2 is 8mm, and the length H1 is 110mm; the filament winding mechanism 9 and the filament package fixing mechanism 12 are both bearing structures, and the inner ring of the bearing is used to be fixed on the hollow fixed shaft 10, and the filament winding The thickness H2 of the machine part 9 and the thickness H4 of the filament package fixing part 12 are both 15 mm, and the outer diameter D3 of the filament winding part 9 and the outer diameter D4 of the filament package fixing part 12 are both 25 mm; Filament package 11 is fixedly installed on the bearing outer ring of long filament package fixed part 12, and the height H3 of long filament package 11 is 70mm; Filament winding mechanism 9 rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com