A carrier spinning method and device thereof

A carrier and recovery device technology, applied in spinning machines, yarns, textiles and papermaking, etc., can solve the problems of insufficient strength and low yarn count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

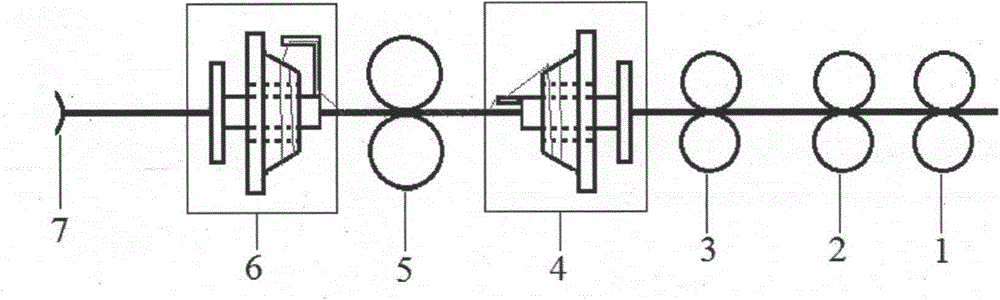

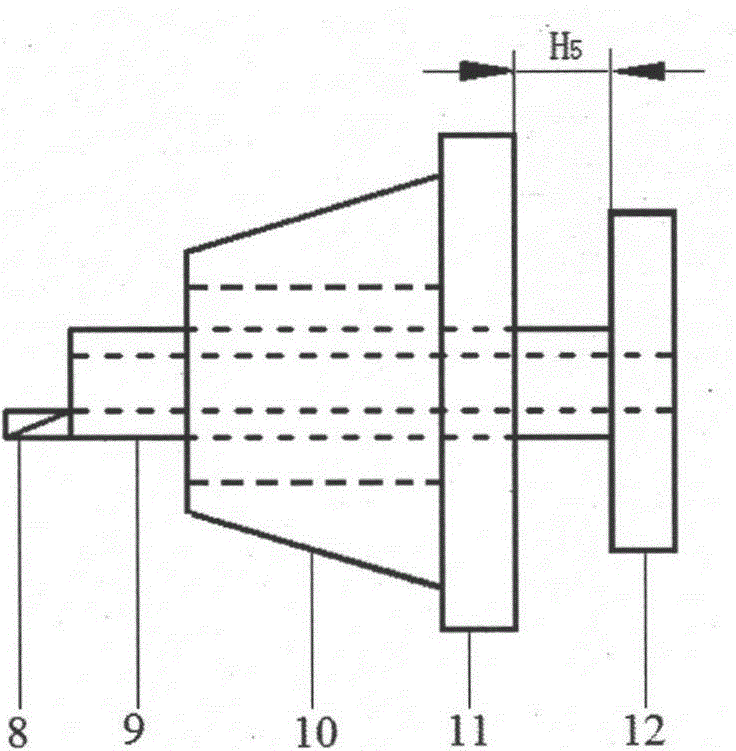

[0038] A carrier spinning device, which includes a front roller 3, a middle roller 2, a rear roller 1, a filament winding device 4, an output roller 5, a filament recovery device 6, a yarn guide hook 7, a front roller 3, and a middle roller 2 1. Back rollers 1 are arranged sequentially from front to back, filament winding device 4 is installed between front roller 3 and output roller 5, and filament recovery device 6 is installed between output roller 5 and yarn guide hook 7. The filament winding device 4 includes three parts: the first part is the filament winding transmission mechanism, which is composed of the winding transmission shaft 9 and the filament winding drive part 12, and the second part is the filament winding mechanism, which is composed of the filament winding mechanism. The package 10 is composed of a package fixing device 11 , and the third part is the winding tension device 8 . The filament recovery device 6 includes three parts: the first part is the filame...

Embodiment 2

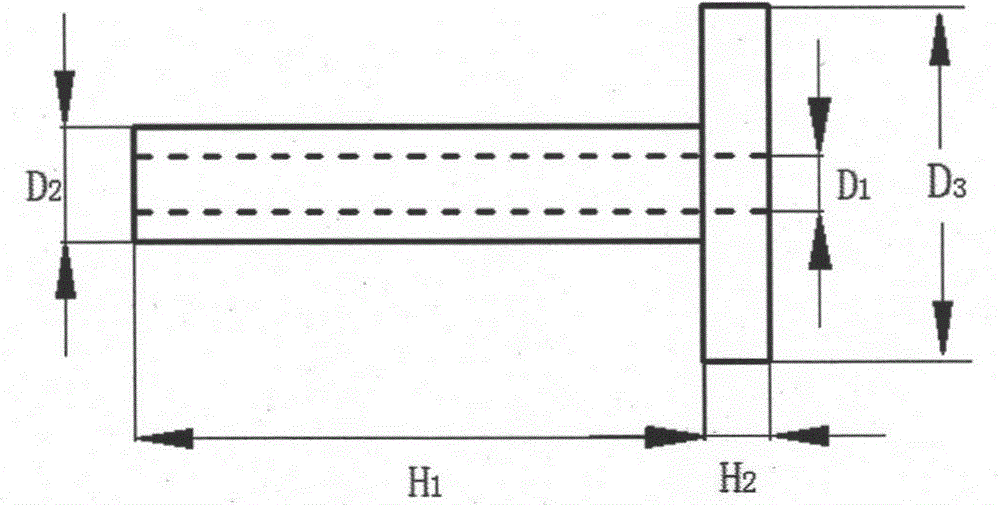

[0051] The draft ratio in the area between the output roller 5 and the front roller 3 is 0.99; the filament winding drive part 12 is a bearing structure, and the inner ring of the bearing is used to be fixed on the spinning machine body, and the outer ring of the bearing is connected to the coil. Connected around the transmission shaft 9, the diameter D3 of the bearing outer ring of the filament winding drive part 12 is 30mm, and the bearing thickness H2 is 10mm; the winding transmission shaft 9 is a hollow structure for the passage of ultra-short fiber strands, and the winding transmission The inner diameter D1 of the shaft 9 is 12mm, the outer diameter D2 is 18mm, and the length is 120mm; the package fixing part 11 is a bearing structure, and the outer ring of the bearing is fixed to the filament package 10, and the inner ring of the bearing is fixed to the spinning machine body. The inner diameter D4 of the bearing of the fixed part 11 is 25mm, its outer diameter D5 is 35mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com