Clamping groove position blocking connection stamping part structure special for T-shaped groove and assembling method

An assembly method and technology of stamping parts, which are applied in the direction of connecting members, shrinkage connections, gaskets, etc., can solve the problems of small technical constraints, high installation costs, and not easy to make mistakes, and achieve small technical constraints, low cost, and not easy to make mistakes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

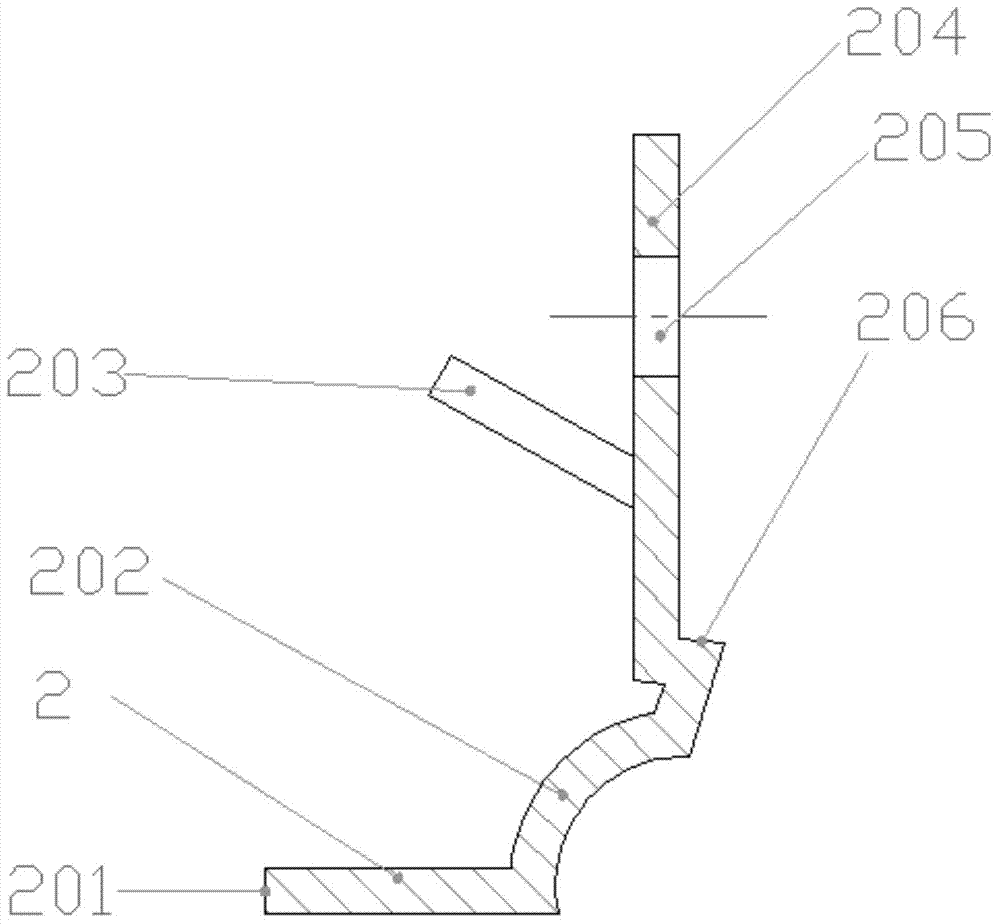

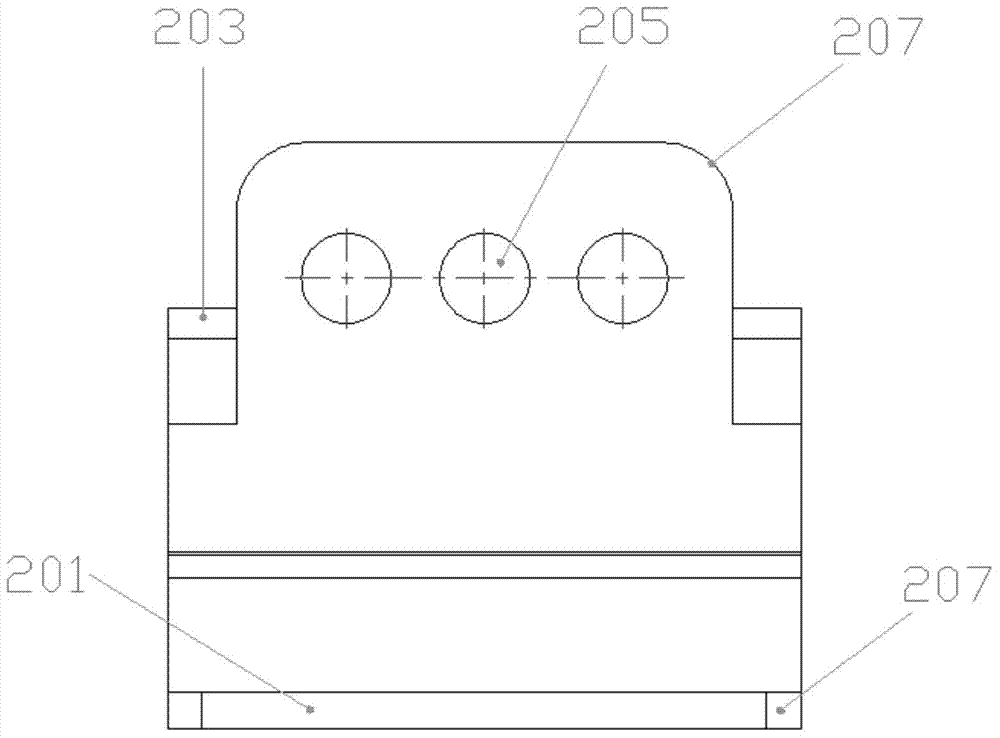

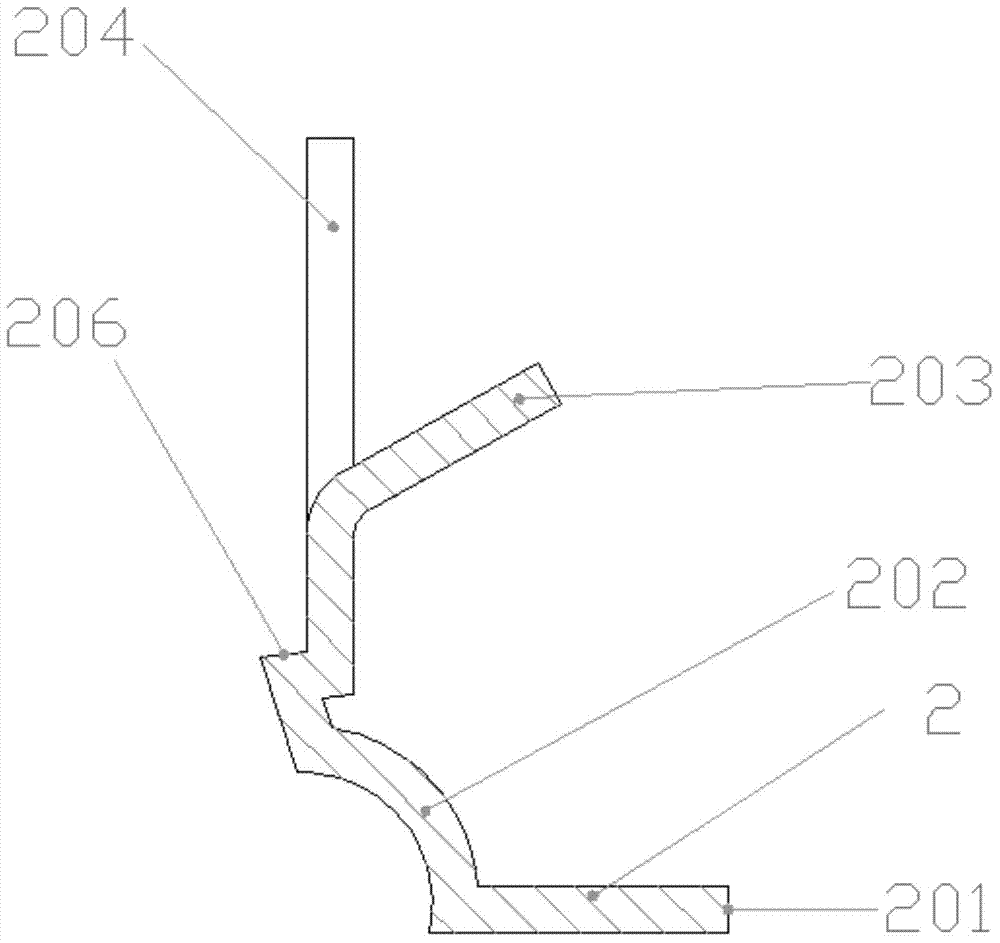

[0031] refer to Figure 1 to Figure 4 As shown, a stamping part structure and assembly method for T-shaped groove special card slot gear connection, including a stamping part structure 2, the stamping part structure 2 is provided with a T-shaped slot bottom limit 201, a T-shaped slot card Hook 206 and connecting panel 204, the T-shaped slot bottom limit 201 is connected with the big head side 101 and the T-shaped slot bottom surface 103 provided by the T-shaped slot 1, and the T-shaped slot hook 206 and the connecting panel 204 are connected with the T-shaped slot. The small head side 102 provided in the groove 1 is connected, the stamping part structure 2 is also provided with a bending positioning limit bar 203, which is snapped into the small head side 102 after bending, and the stamping part structure 2 is also provided with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com