Hypersonic aircraft elevator fault control method

A hypersonic, aircraft technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of aircraft influence, complex flight dynamics characteristics of hypersonic aircraft, large uncertainty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

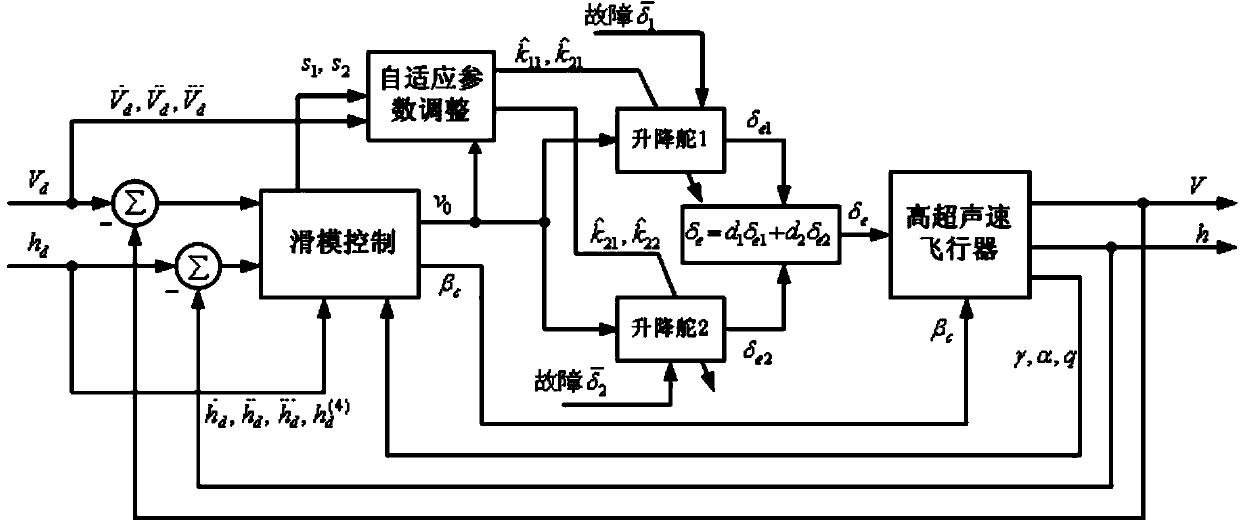

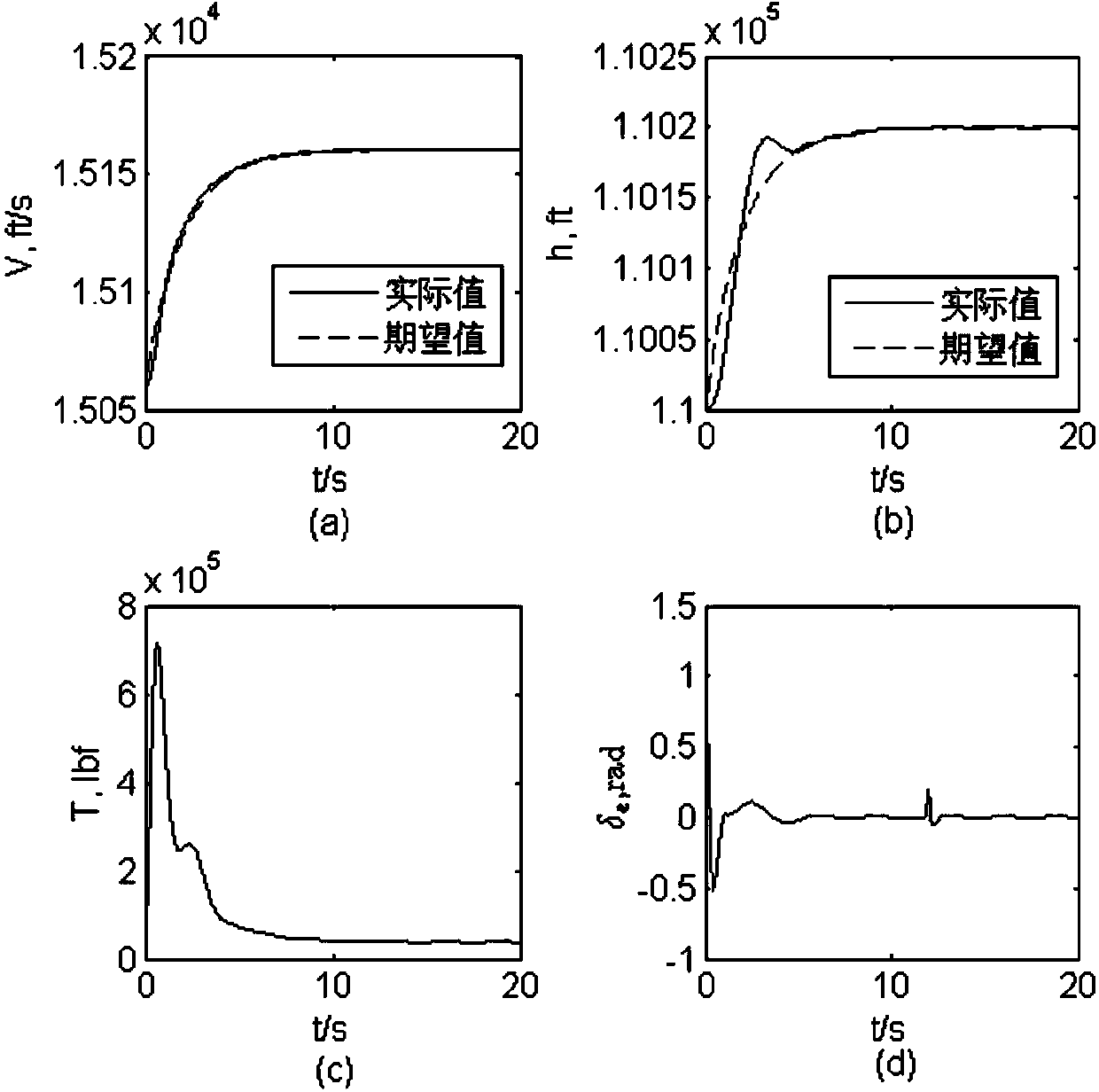

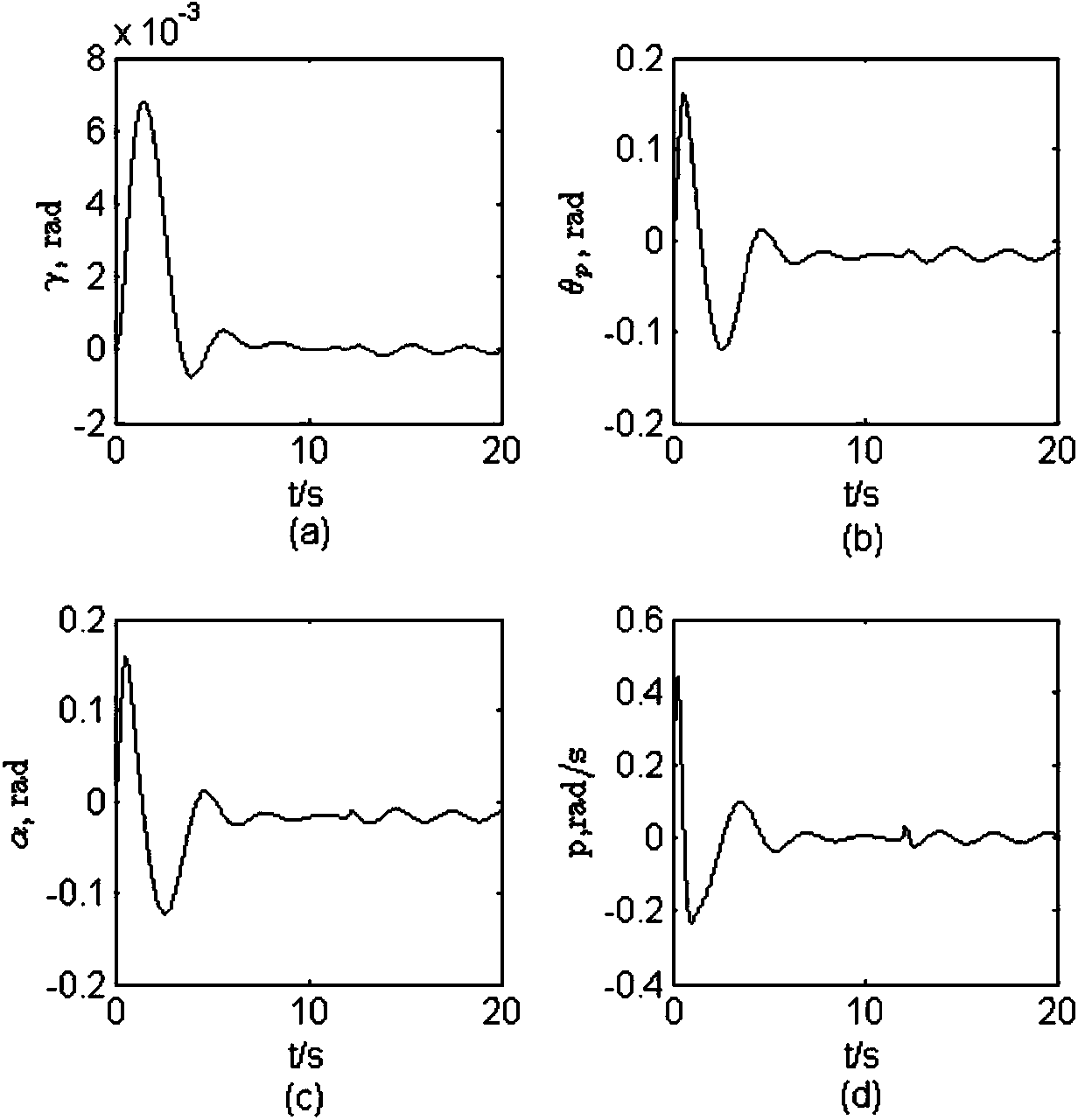

[0073] Below in conjunction with accompanying drawing, a kind of hypersonic vehicle elevator failure control method proposed by the present invention is described in detail:

[0074] The present invention provides a kind of hypersonic vehicle elevator failure control method, comprising the following steps:

[0075] Step 1, establish the longitudinal kinematics and dynamics model of the cruise segment of the hypersonic vehicle, the model is expressed as:

[0076] V · = T cos α - D m - μ sin γ r 2

[0077] γ · = L + T sin α mV - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com