Tackle for paying off underground laid cable

A technology of pay-off pulley and underground laying, which is applied to cable installation, cable installation, and cable laying equipment in underground pipelines. , Easy to use, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

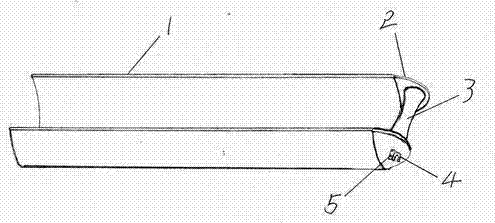

[0008] The embodiment is described in detail in conjunction with the accompanying drawings. In the present invention, a connecting plate 2 protruding outward in an arc shape is respectively welded on the side walls of one end of a metal semicircular tube groove plate 1, and a connecting plate 2 is installed between the middle parts of the two connecting plates. A fixed shaft 5 is installed with a pay-off pulley 3 with a bearing on the fixed shaft, and a U-shaped snap ring 4 is respectively arranged at the two ends of the fixed shaft 5 . The length of the above-mentioned grooved plate is 1-1.2 meters, and the inner diameter is 12cm. When it is used for laying cables underground, place it on the upper part of the laying cable, first clamp the pulley outside the plastic protective tube that needs to pass, then push the slot plate along the cable into the protective tube, the pulley stays at the outer end of the protective tube, and when the cable moves As the pulley rolls, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com