Combined type flat cloth bag pulse dust collector

A pulsed dust collector and combined technology, applied in combined devices, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of weak cleaning ability, low dust removal efficiency, and high emission concentration, and achieve strong cleaning ability and dust removal. The effect of high efficiency and low emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

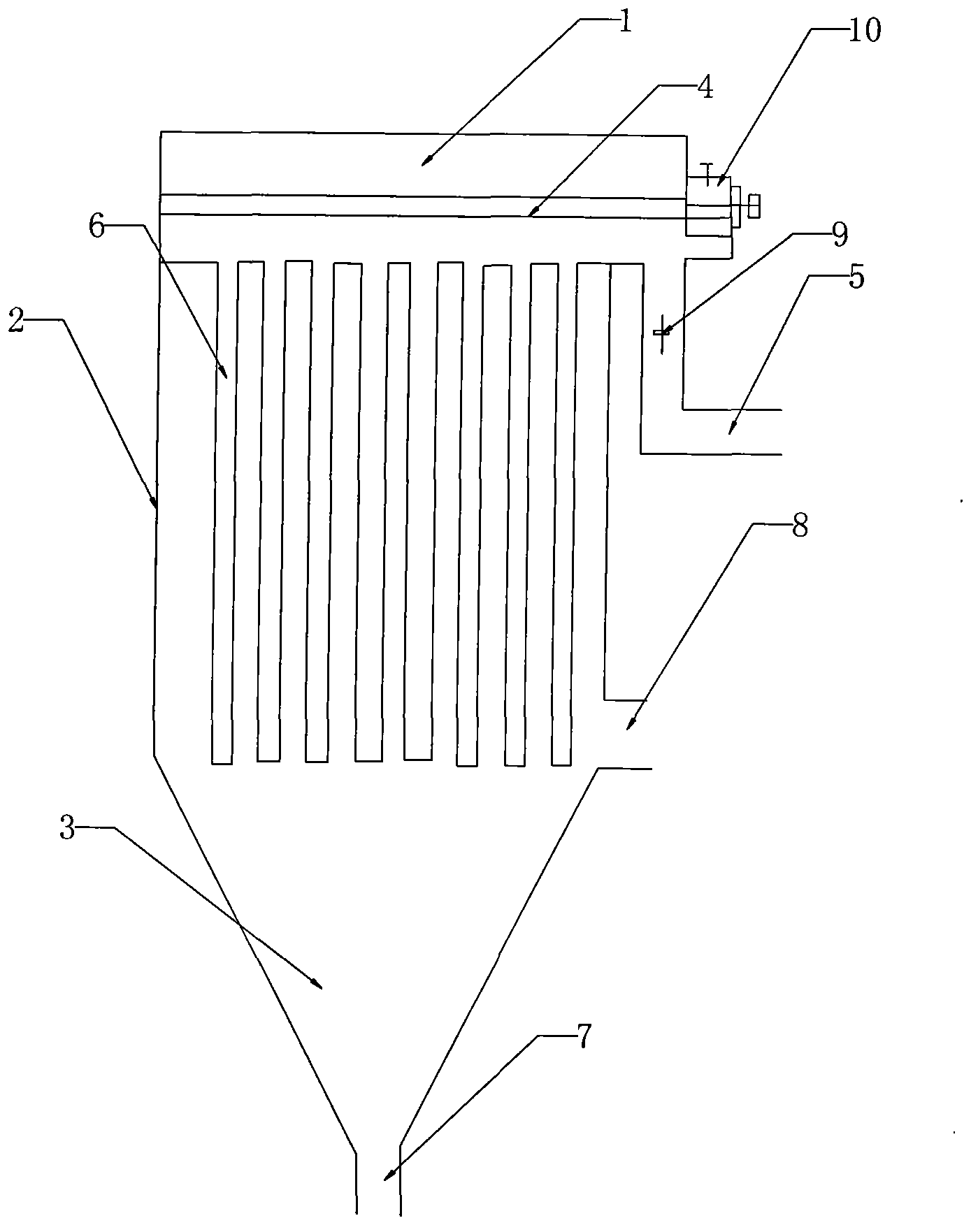

[0010] Such as figure 1 As shown, a combined flat bag pulse dust collector includes an upper box body 1, a middle box body 2 and a lower box body 3 assembled from top to bottom. The middle part of the upper box body 1 is welded with a cover plate 4, and the upper box body The bottom of the box body 1 is provided with an air outlet 5, the air outlet pipe is provided with a poppet valve 9, the outer side of the upper box body 1 is provided with a pulse valve 10, and the middle box body 2 is welded with eight filter bags 6, the length of each filter bag 1.2m, the lower box 3 is provided with an ash hopper 7 and an air inlet 8.

[0011] The dust-laden gas enters the middle b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com