Dust removal and cooling device of cold pilger mill

A technology of cooling device and cold rolling mill, which is applied in the direction of metal rolling, metal rolling, and keeping roll equipment in an effective state, can solve the problems of affecting the working process, high maintenance costs, and affecting the service life of the main motor, etc., to achieve Make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

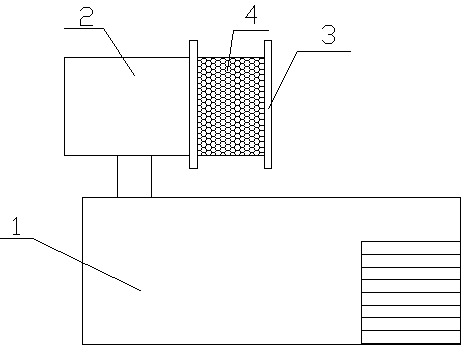

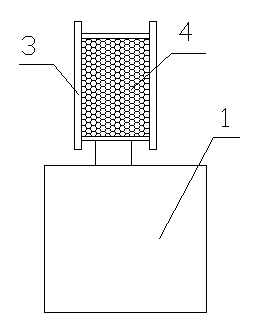

[0012] like figure 1 , 2 Shown: The dust removal and cooling device for a cold rolling mill in this embodiment includes a main motor 1, a blower 2, one end of the blower 2 is connected to the main motor 1, and the other end is fixedly connected to an air inlet filter device.

[0013] The air inlet filter device includes a dust cover 4 and an air inlet frame 3, the air inlet frame 3 is fixedly connected with the air inlet of the blower 2, and each surface of the air inlet frame 3 is fixed with the air inlet frame 3. Dust cover 4.

[0014] The beneficial effects of this embodiment are: the main motor can be cooled and dust and impurities can be prevented from entering the main motor, so as to ensure that the cold rolling mill can work smoothly and improve the work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com