Track polishing device for polishing stainless steel rod

A technology of polishing device and stainless steel rod, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, metal processing equipment, etc., can solve the time-consuming and laborious grinding effect, the uneven surface of stainless steel rods, the influence of poor gloss, etc. Problems, Achieve the effect of improving work efficiency, good polishing effect and improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

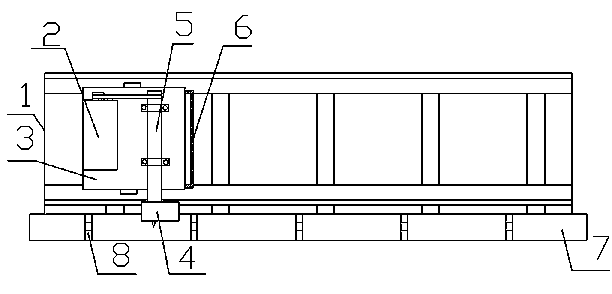

[0011] Such as figure 1 Shown: a kind of track polishing device of polishing stainless steel bar of the present embodiment, comprises bracket 1, motor 2, trolley 3, polishing cloth wheel 4, wherein one side of said bracket 1 is provided with slideway, described trolley 3 The pulleys at the bottom are respectively placed on the slideways to slide, and one end of the trolley 3 is provided with a handle 6 .

[0012] Wherein rotating shaft 5 and described motor 2 are respectively fixed on described dolly 3, and one end of described rotating shaft 5 is connected with described motor 2 by belt, and the other end fixes described polishing cloth wheel 4; Wherein described rotating shaft 5 and described One end of the fixed connection of the polishing cloth wheel 4 is set in a tapered shape.

[0013] A polishing plate 7 is arranged on the support 1 , and five card slots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com