Quantitative putting-in bottle

A bottle cap and bottle body technology, which is applied in the field of quantitative delivery containers, can solve the problems of inconvenient use of milk powder cans, easy contamination of milk powder by bacteria and water vapor, and the inability to quantitatively take out the contents, achieving a compact structure, not easy to spill, and isolation of pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and drawings of the present invention.

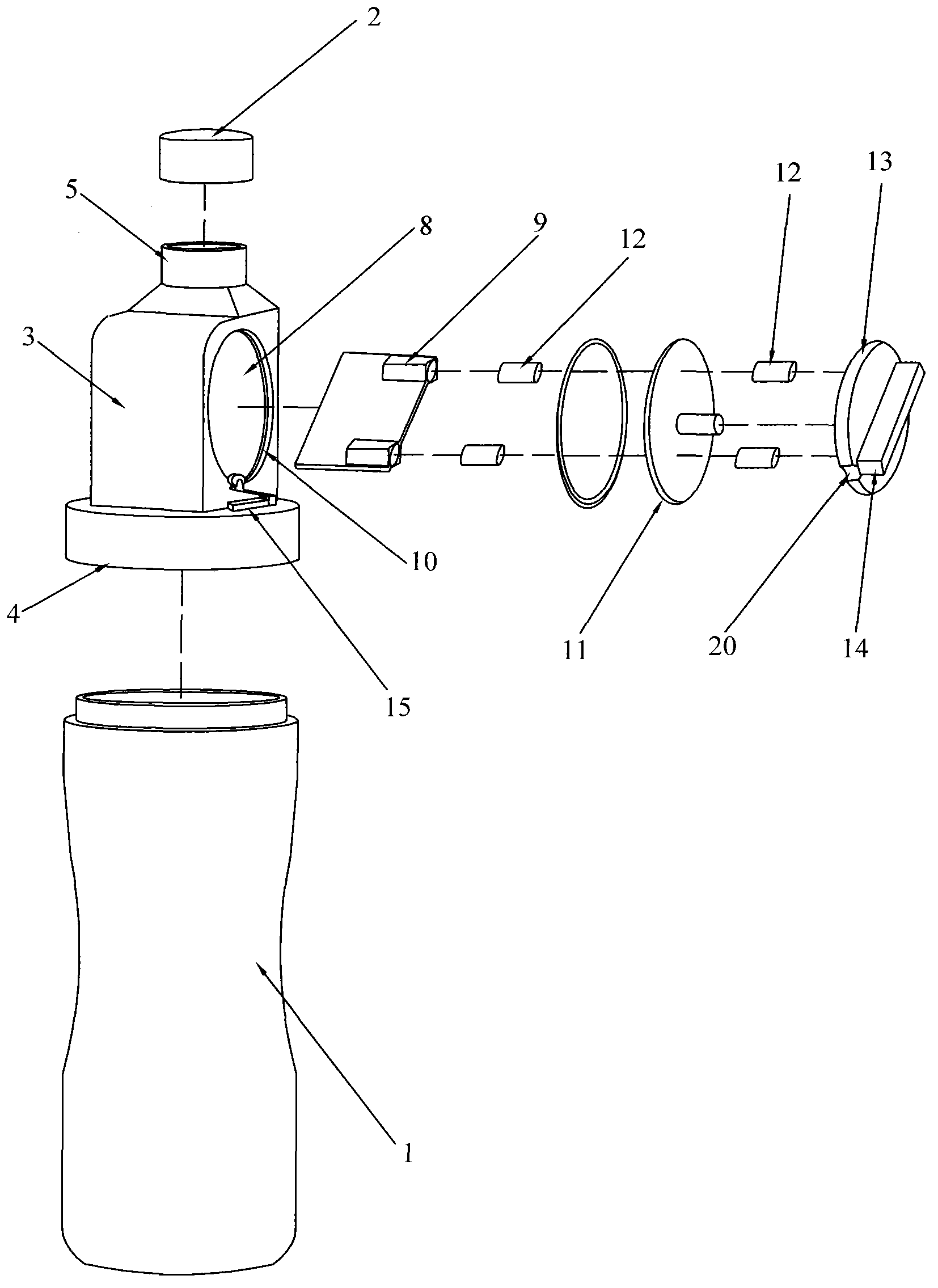

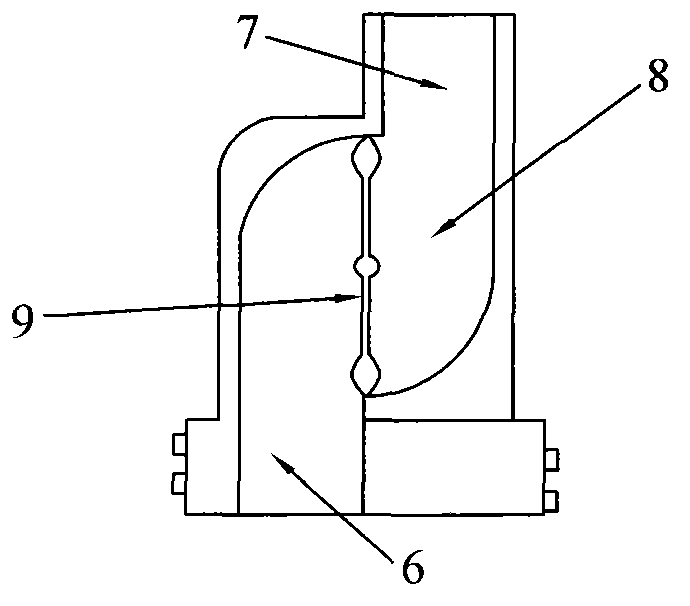

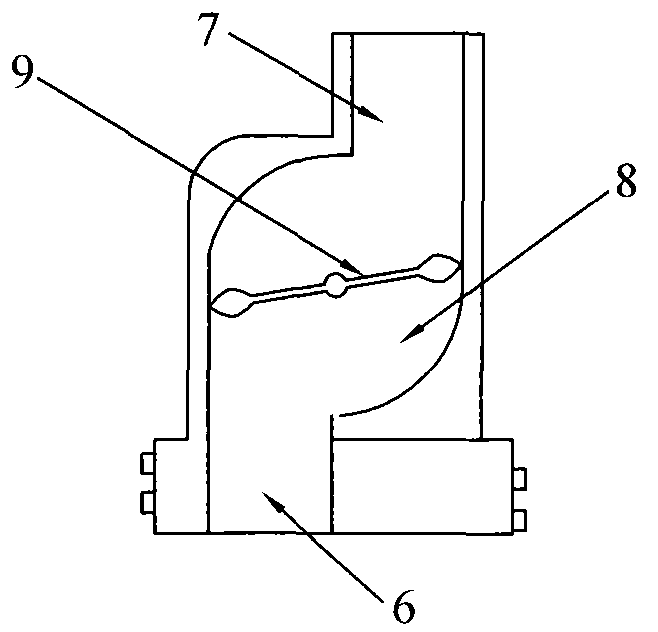

[0033] See Figure 1 to Figure 5 As shown, the present invention provides a quantitative dispensing bottle, including a bottle body 1 and a bottle cap 2, which also includes a conducting seat 3, the bottom of the conducting seat has a bottle mouth interface 4, the top surface has The bottle cap interface 5 has a material path connecting the bottle mouth interface and the bottle cap interface inside. The material path includes a bottle side material whose bottom end is connected to the bottle mouth interface and the top end extends to the middle section of the conducting seat. The channel 6 also includes a cap-side material channel 7 with a top end communicating with the bottle cap interface and a bottom end extending to the middle section of the conducting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com