grouting method

A technology for grouting holes and mortar, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc. It can solve the problems of not being able to adjust the viscosity of materials, control the diffusion distance, and unfavorable cost control at the same time, so as to be suitable for large-scale applications and simplify grouting The effect of process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as Figure 1 to Figure 5 Shown is a specific embodiment of the grouting method according to the present invention. It includes the following steps:

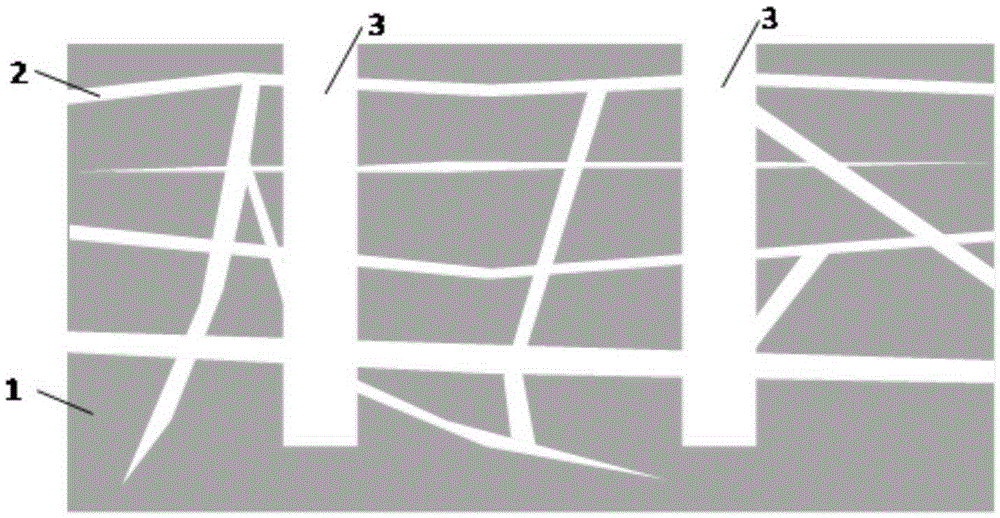

[0034] 1) Determine the grouting area 1, and complete the layout of the grouting holes 3, such as figure 1 shown.

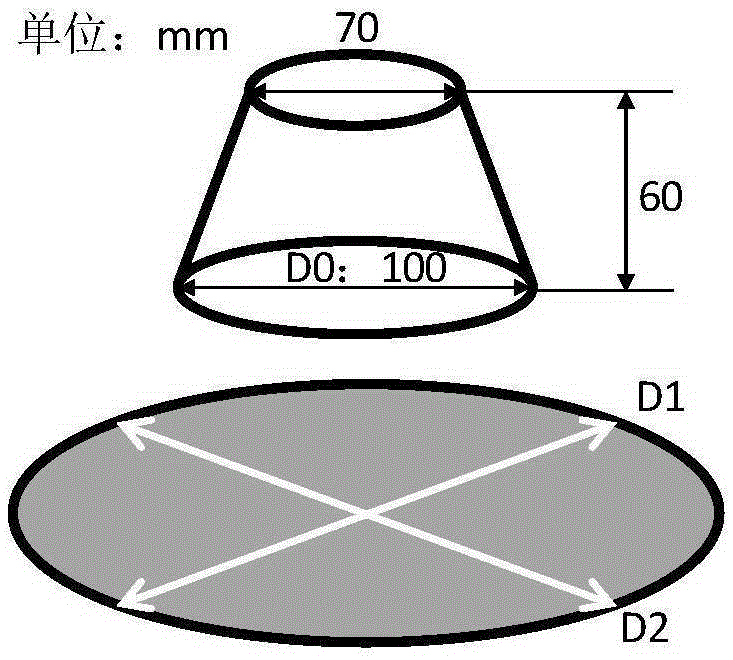

[0035] 2) Determine the flow performance and viscosity of the grouting mortar based on the hole spacing between the grouting holes 3 and the width of the crack 2 . In this embodiment, the viscosity of the mortar is measured by evaluating the passing time of the mortar passing through the V-shaped funnel, and the fluidity performance of the mortar is evaluated by the test result of the degree of expansion of the mortar.

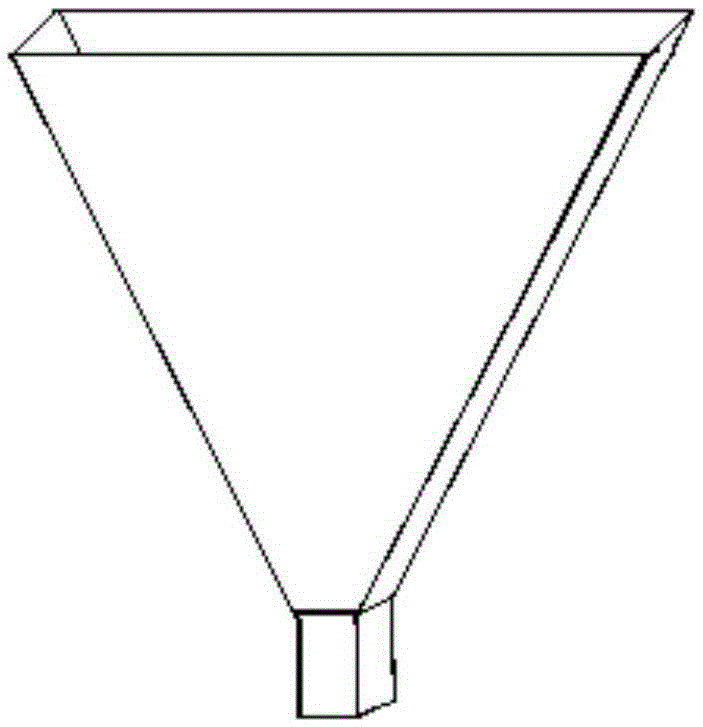

[0036] in, figure 2A schematic diagram of the structure of a V-shaped funnel is shown. The upper opening of the V-shaped funnel is 270mm×30mm, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com