A pump guide

A technology for guides and pumps, applied in the field of rotating machinery, can solve the problems of high vibration pulsation level and narrow working range, and achieve the effects of high shell strength and simple and effective structure scheme.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

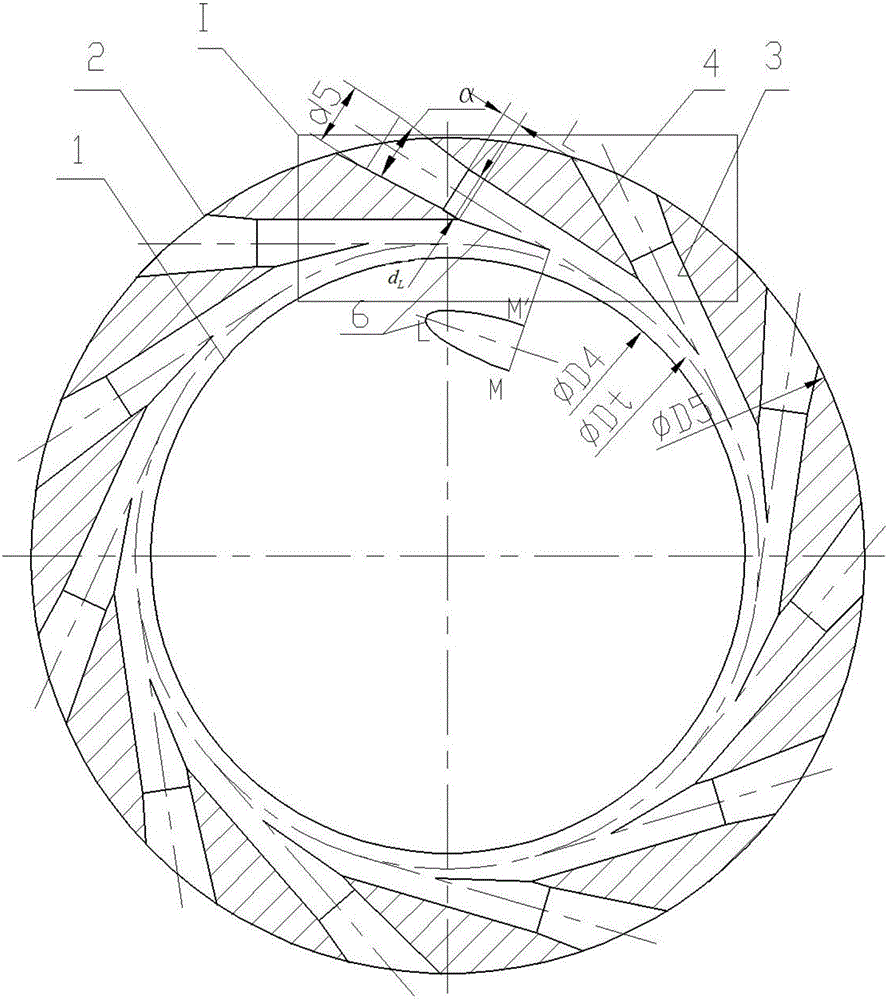

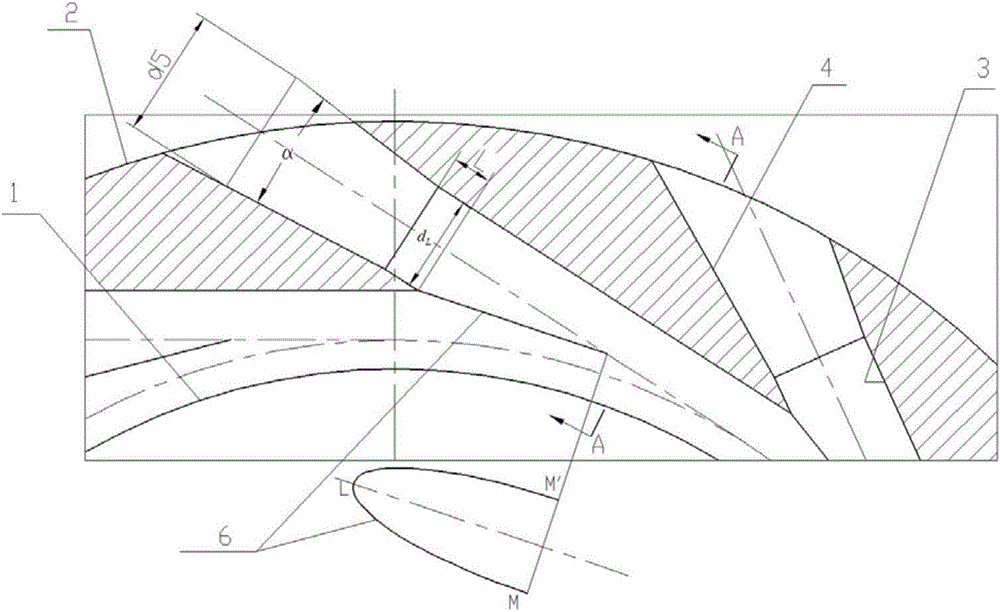

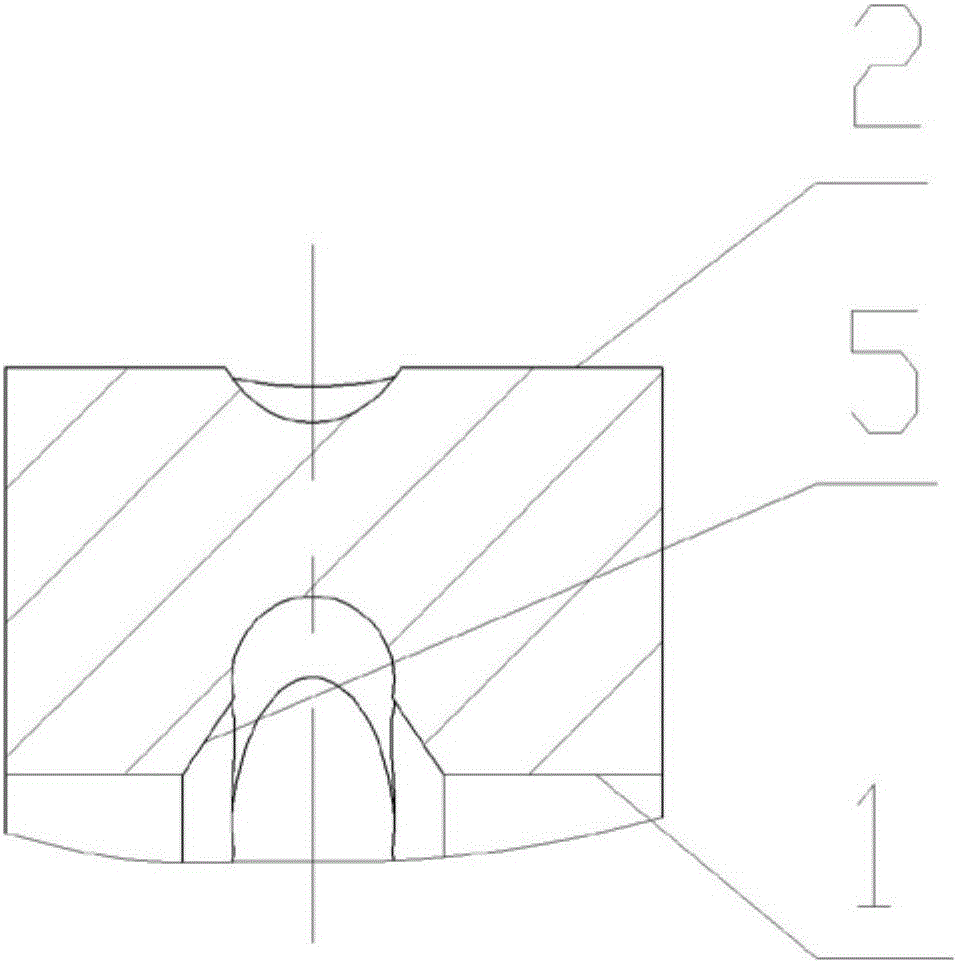

[0026] figure 1 It is a front view of the pump guide device of the present invention, which is also a preferred embodiment of the present invention. The main structure is an annular part tightly surrounding the outlet of the impeller. Channels are provided on the annular part as guides, and at the outlet of the guides is a liquid collector with an annular space. The ring part comprises: an inner cylindrical surface (inner surface) 1 of the ring; an outer cylindrical surface (outer surface) 2 of the ring; a group of circumferentially uniform passages extending substantially radially from the inner surface to the outer surface, the cross section of the passage being a circle, The centerline of the channel is a straight line. The size of each channel of the guide increases along the flow direction of the impeller, and each channel is composed of an inlet cylindrical section (straight section) 3, a combination of an outlet conical section (flared section) 4, and the maximum diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com