Multiple-effect cyclone separating device

A cyclone separator and pre-separation technology, which is applied in the direction of the swirl device and the device whose axial direction of the swirl can be reversed, etc., can solve the problems of unstable flow pattern, short service life, and large equipment wear, and achieve the elimination of secondary Secondary flow, long service life and less equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

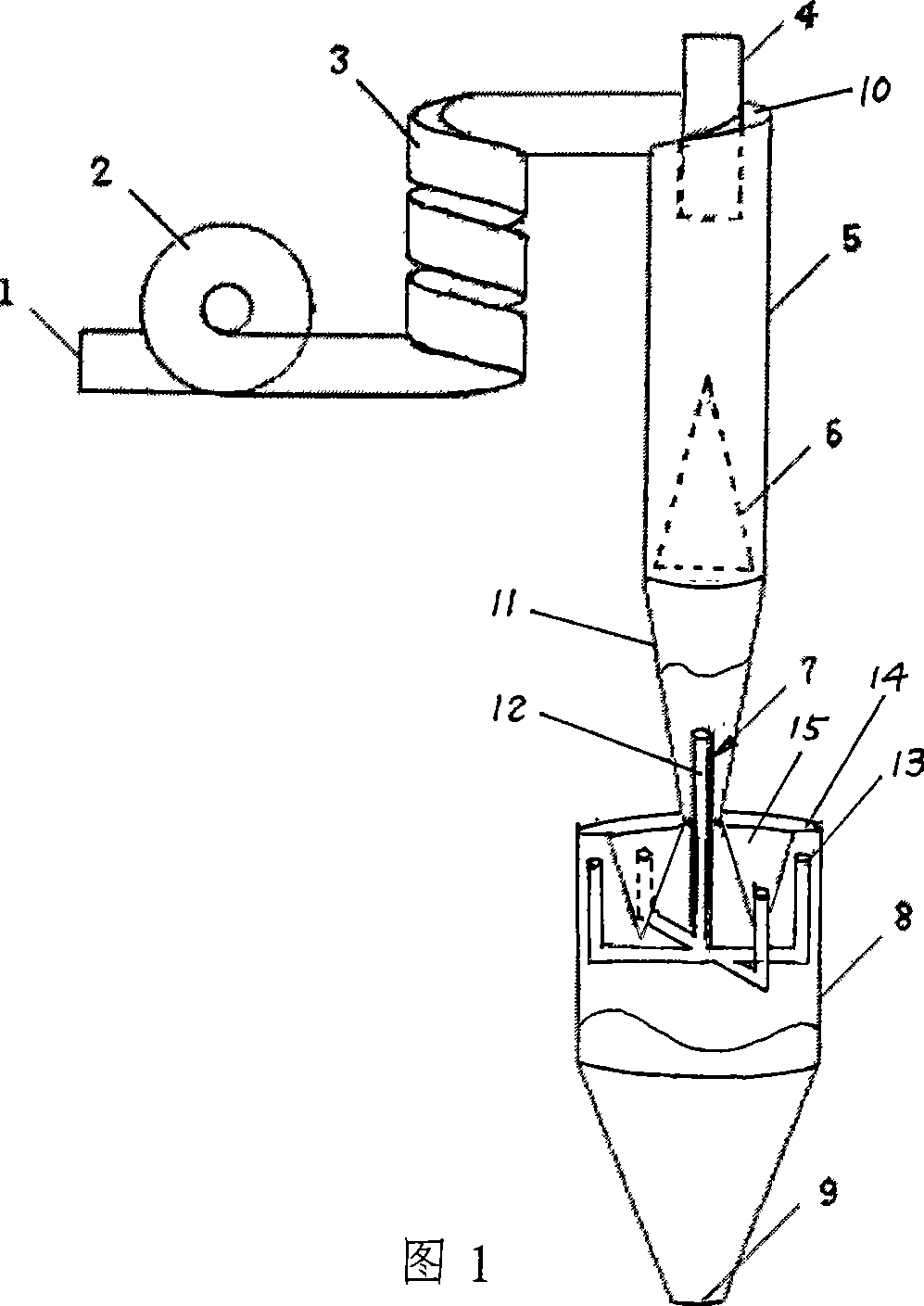

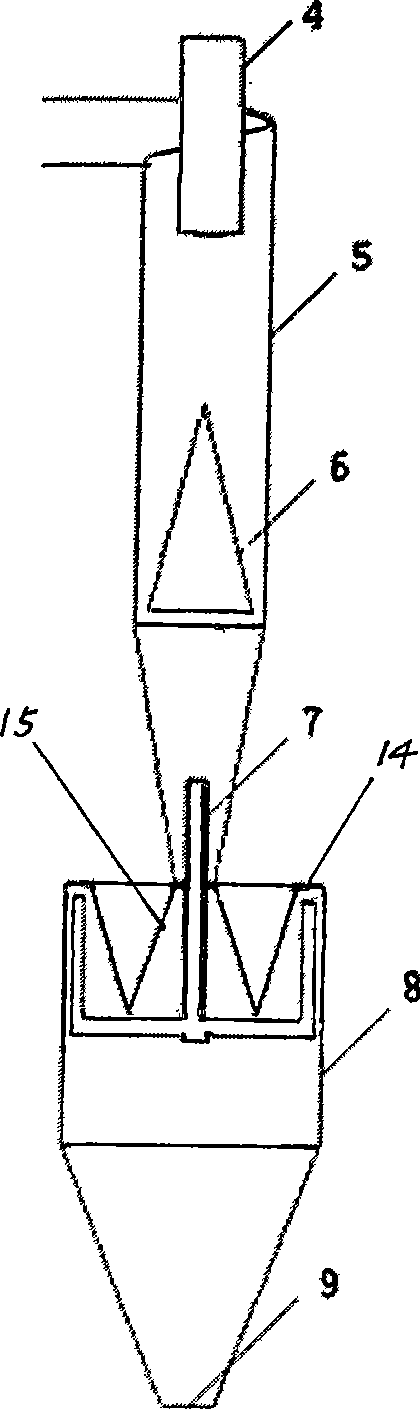

[0016] Example 1. A multi-effect cyclone separator, such as figure 1 , figure 2 Shown. It includes the main body shell. The main body shell includes an upper cylindrical body 5, a spiral top cover plate 10 fixed on the upper cylindrical body 5, and a lower inverted cone cylindrical body 11 fixed on the lower end of the upper cylindrical body 5. The exhaust pipe 4 is installed in the middle of the spiral top cover plate 10 and extends into the upper cylindrical body 5. An ash bin 8 with an ash discharge port 9 at the lower end is fixed at the lower end of the inverted cone shell 11. The air inlet 1 is tangentially installed on the upper end of the upper cylindrical body 5 via the vertical α-shaped first-stage pre-separation spiral pipe 2 and the second-stage pre-separation spiral pipe 3 connected in sequence. The cross sections of the air inlet 1 and the first-stage pre-separation spiral pipe 2 and the second-stage pre-separation spiral pipe 3 are all rectangular. The rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com