Variable air gap disc-shaped linear induction traction motor high-speed mutual feedback table for track traffic

A linear induction motor and rail transit technology, applied in the field of electric traction drive, can solve the problems of large space and investment, high speed of linear induction traction motor, and achieve the effects of energy saving, small size and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention is further described below in conjunction with the drawings and embodiments.

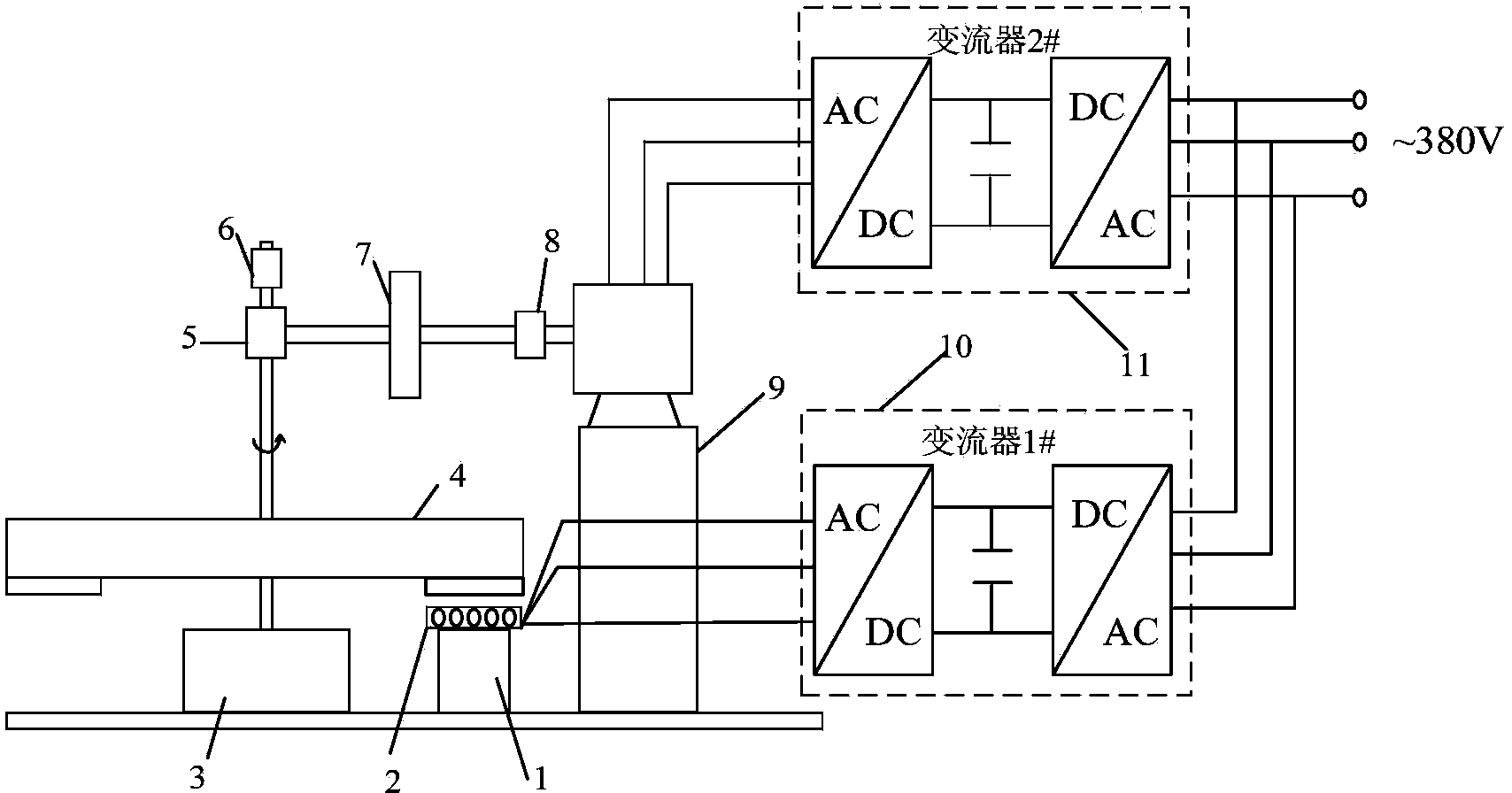

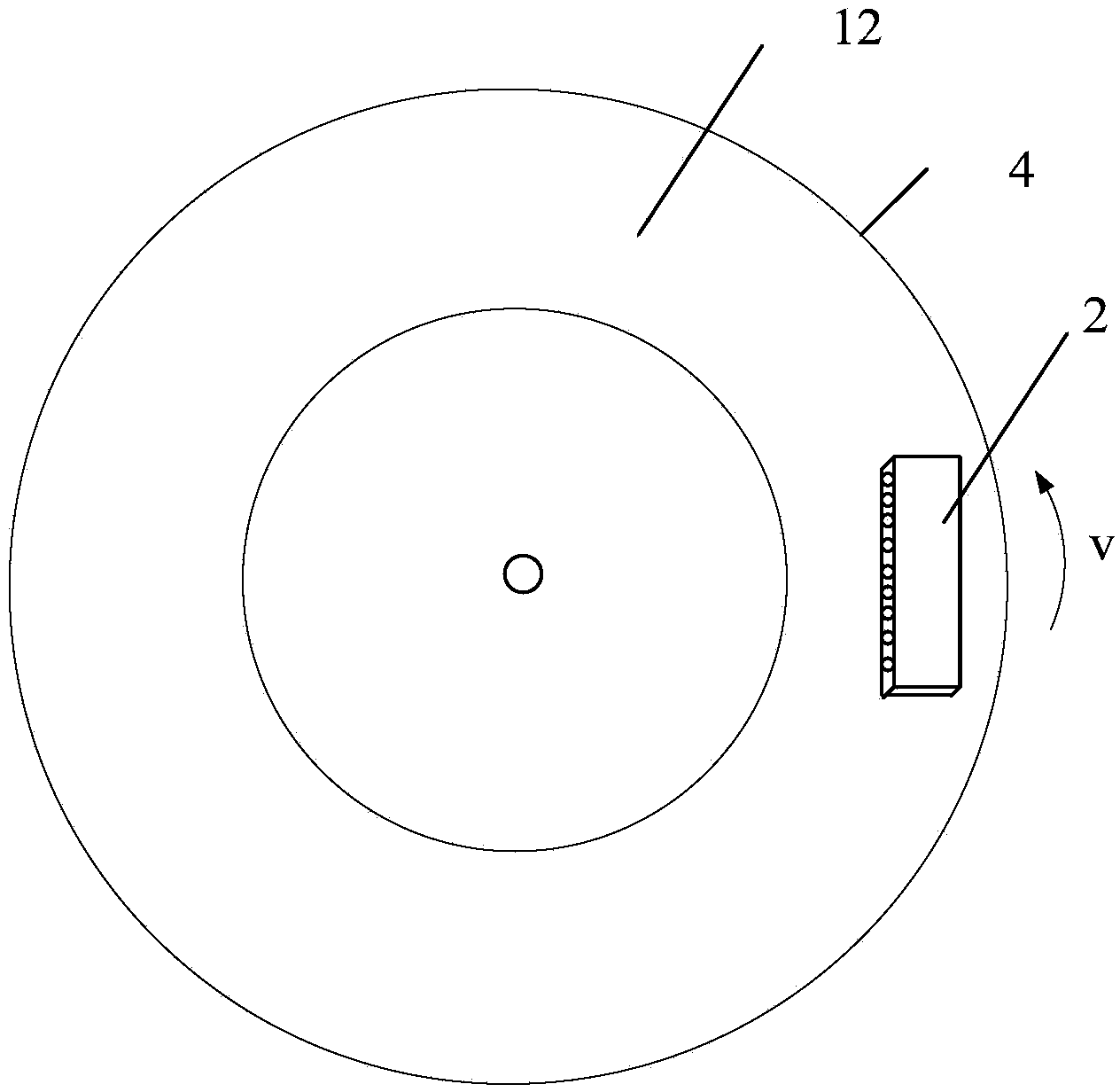

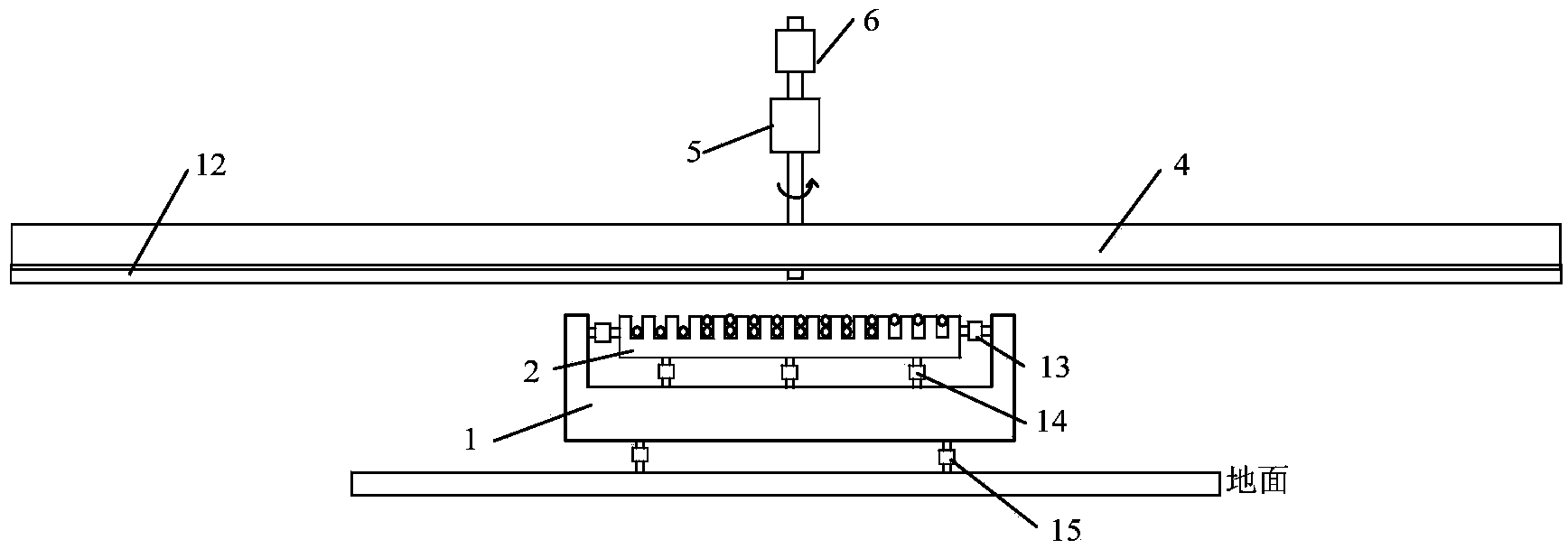

[0030] Such as figure 1 Shown is a high-speed mutual-feeding platform for variable air gap disc linear induction traction motors for rail transit; the device consists of a primary base 1, a linear induction motor primary 2, a secondary support platform 3, a disc-shaped secondary 4, and an umbrella-shaped coupling Shaft 5, rotary encoder 6, flywheel 7, torque meter 8, rotary induction motor 9, No. 1 converter 10, No. 2 converter 11.

[0031] (1) Primary base 1. The primary base 1 is used to fix the primary 2 of the linear induction motor, and at the same time, a tension and compression sensor is installed at the connection part between the primary 2 of the linear induction motor and the primary base 1. The tension and compression sensors include a thrust sensor 13, a normal force sensor 14, and a lateral force sensor 16, which are used to detect thrust, normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com