Ultrasound transducer assembly and method of manufacturing the same

一种超声换能器、组件的技术,应用在超声换能器元件,制造这样的超声换能器组件领域,能够解决不容易制造、换能器组件复杂等问题,达到简单制造方式的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

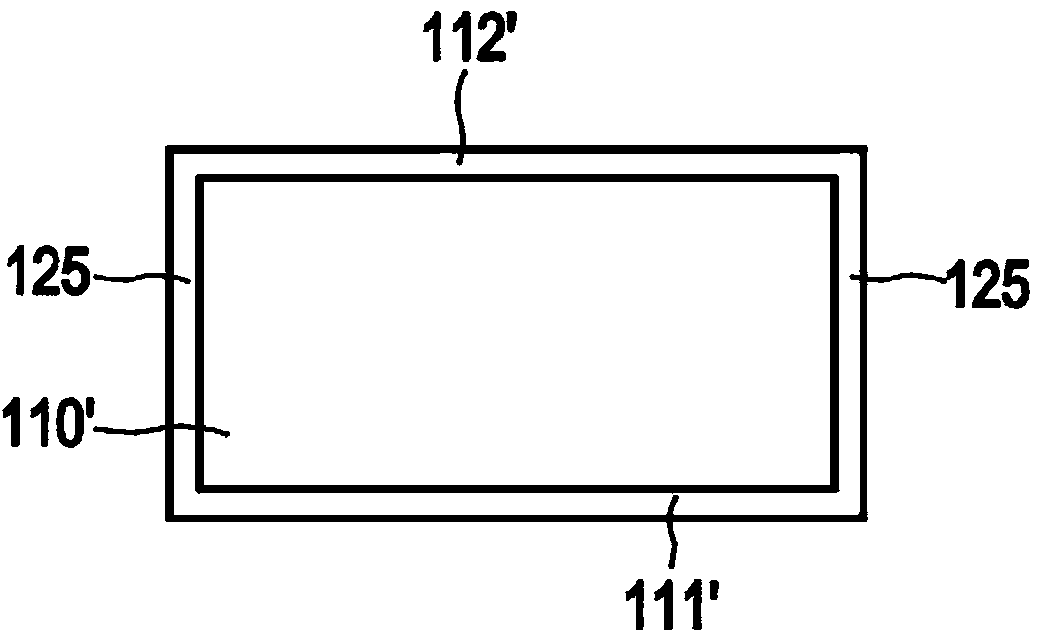

[0027] figure 1 A cross-sectional view of an ultrasound transducer assembly 100 according to an embodiment is shown. The ultrasound transducer assembly 100 comprises ultrasound transducer elements 175 , 175 a for emitting ultrasound waves in a general direction of transmission A . The ultrasound transducer elements 175, 175a may be arranged in a (one-dimensional) row or a (two-dimensional) array. For simplification purposes, the figure 1 Only three of the described ultrasonic transducer elements are illustrated in the cross-sectional view of . It should be understood that there may be any number of additional ultrasound transducer elements arranged in a row or array.

[0028] exist figure 1 In an embodiment of the present invention, each of the ultrasonic transducer elements 175, 175a includes a piezoelectric layer 110, 110a having upper, lower and side surfaces relative to the general direction of transmission A . Each of the upper and lower surfaces of the piezoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com