Working position tool of back seat cushion support of automobile and using method thereof

A technology for workstation appliances and back seats, applied in the directions of external frames, manual conveying devices, packaging, etc., can solve the quality requirements of material boxes or storage cages to ensure storage and transportation, and the high dimensional accuracy requirements of installation holes and assembly surfaces. Manual handling and other problems, to achieve the effect of convenient and quick pick and place, convenient operation, and solve the problem of workpiece bumping and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

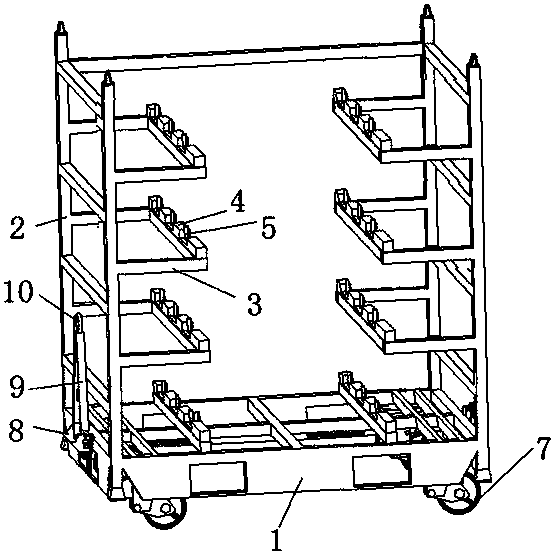

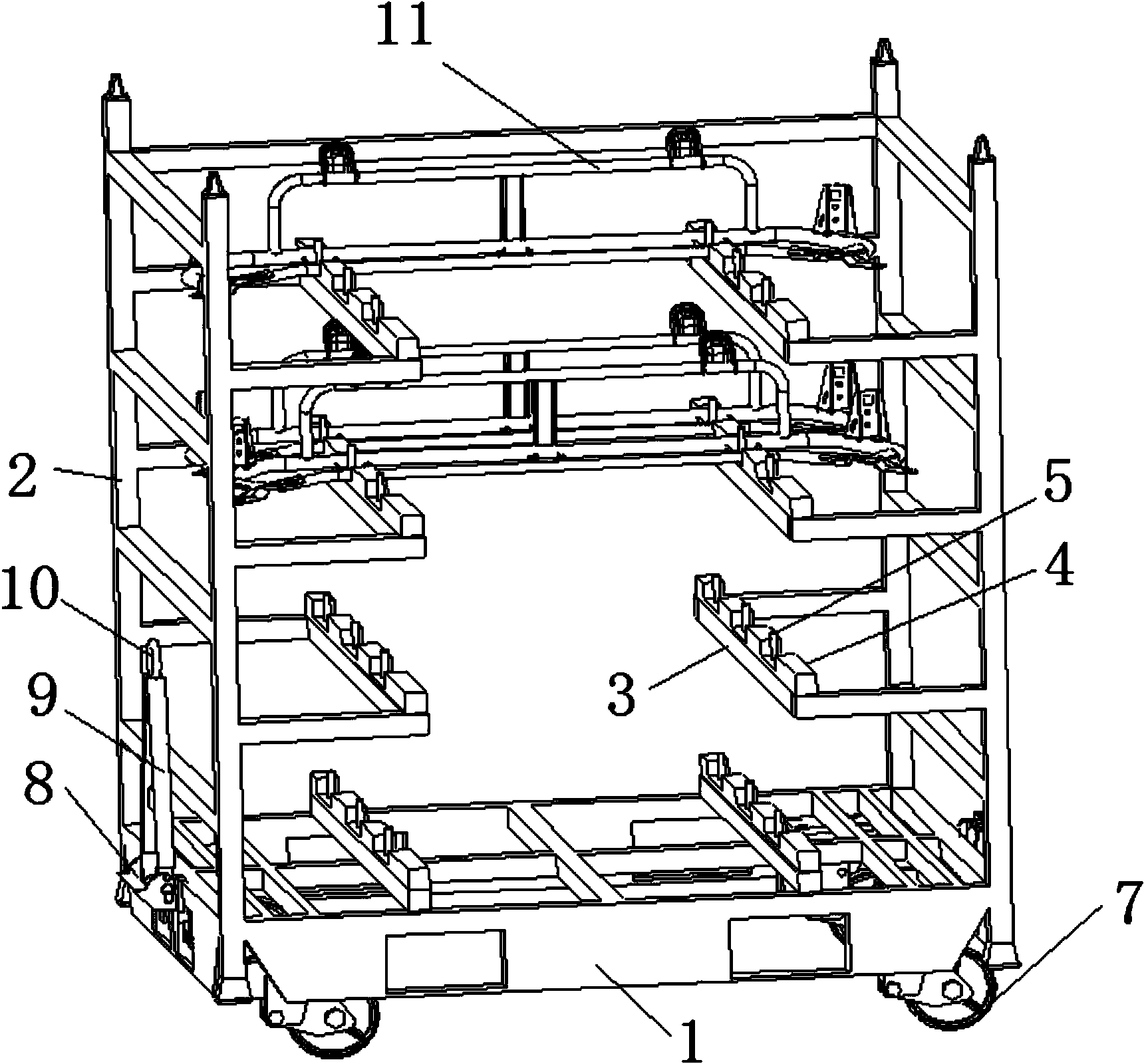

[0016] Such as Figure 1 ~ Figure 2 Shown is a station appliance for a rear seat cushion support of an automobile, comprising a base 1 and an appliance frame 2 arranged on the base. The insides of the side frames on both sides of the appliance frame 2 are respectively provided with correspondingly arranged storage platforms 3, and the storage platforms 3 are provided with There are a plurality of limiting blocks 4, and a card slot is formed between adjacent limiting blocks 4, and the width of the card slot is adapted to the end of the rear seat cushion support 11 of the automobile. The bottom of the slot protrudes from the positioning pin 5 with a height higher than the limit block 4. If the height of the positioning pin 5 is lower than the limit block 4, during the transportation, shaking will make the set pin on the positioning pin The perforation on the rear seat cushion support of the automobile breaks away from the positioning pin 5, causing the rear seat cushion support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com