Transferring device used for upper-lower catwalk of pipe rod

A technology for moving devices and catwalks, which is applied in the direction of drill pipes, drill pipes, casings, etc., and can solve the problems of easy injury, manpower and time consumption, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

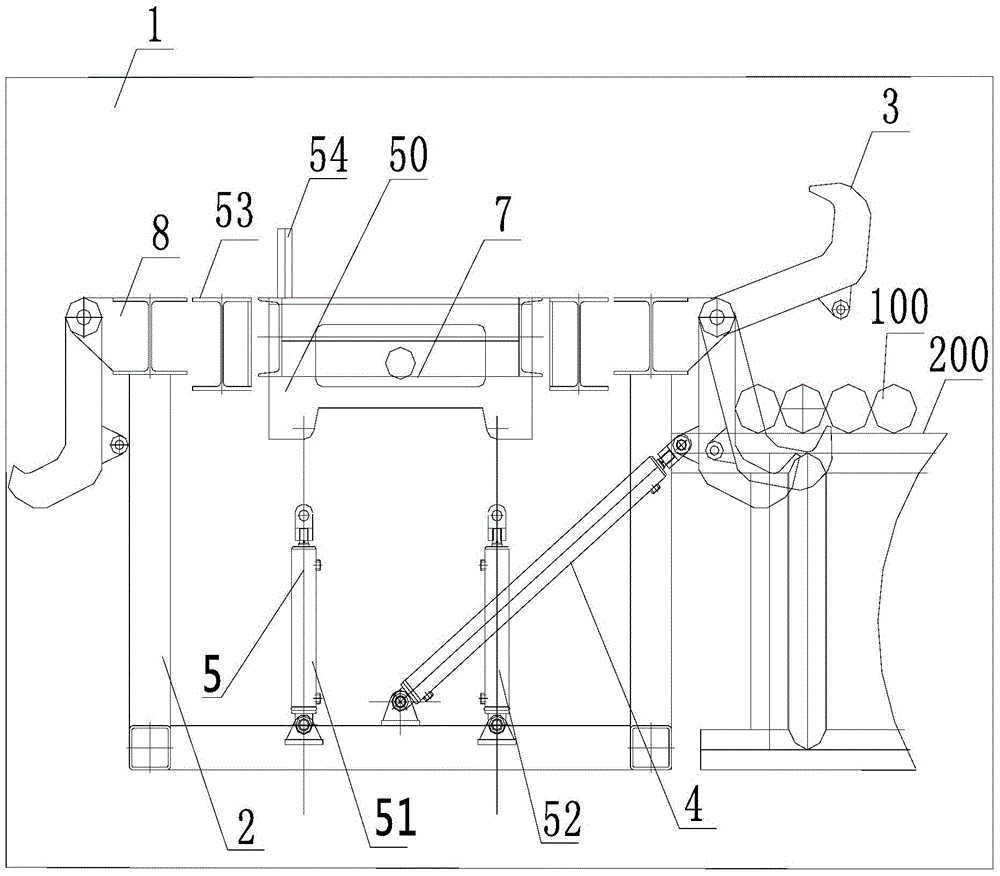

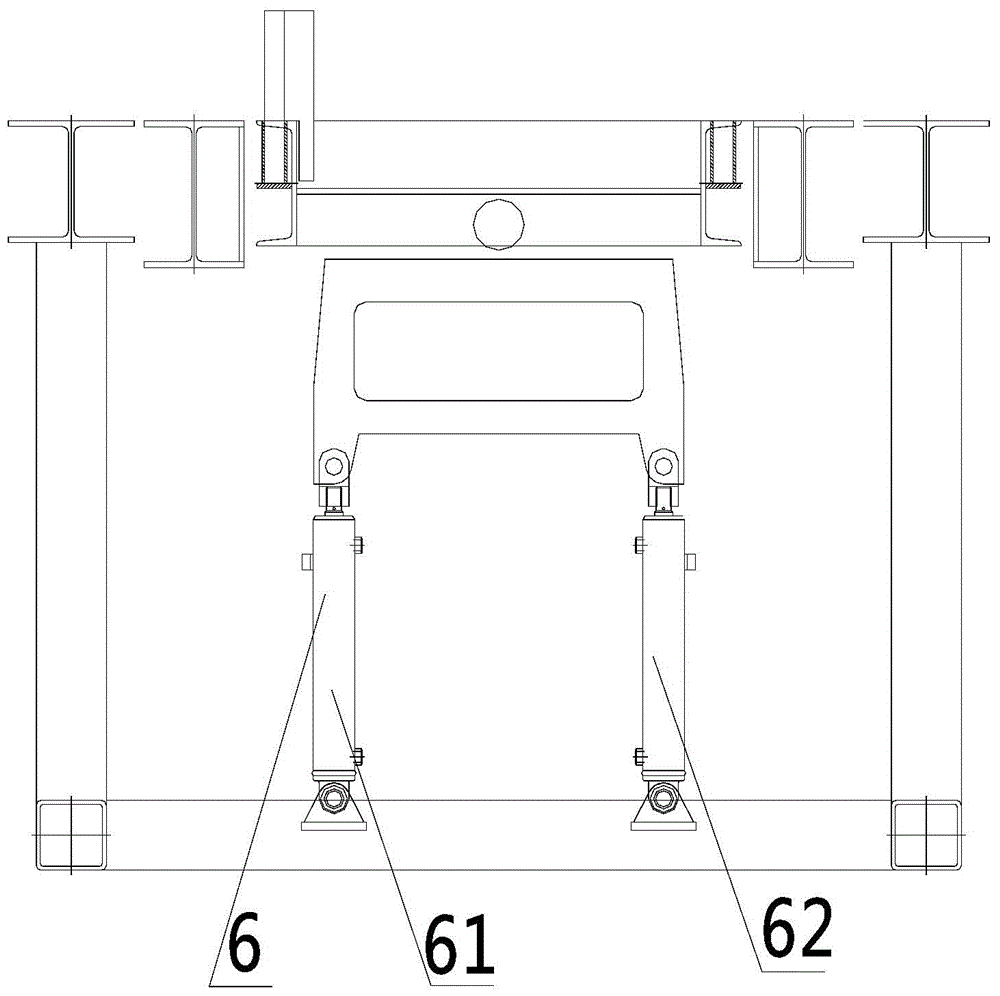

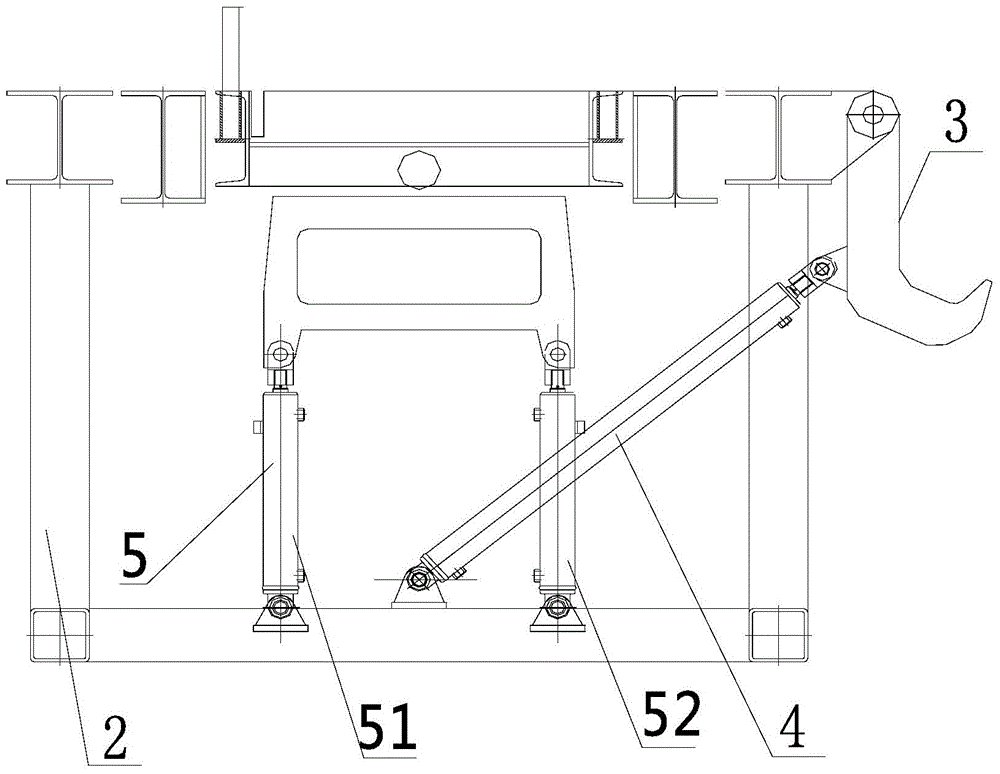

[0023] see figure 1 with Figure 5 According to the first embodiment of the present invention, a transfer device 1 for pipe rods up and down catwalks includes a catwalk support 2, a rotating arm 3, an inclined hydraulic device 4, a front pipe rod lifting device 5 and a rear pipe rod Lifting device 6 ( Figure 5 shown in);

[0024] Wherein: the rotating arm 3 is arranged at the two ends of the catwalk support, and is respectively hinged with the two ends of the catwalk support 2; the oblique hydraulic device 4 is used to drive the rotating arm;

[0025] The front pipe rod lifting device 5 includes a top plate 50, a first vertical hydraulic device 51 and a second vertical hydraulic device 52; the first vertical hydraulic device 51 and the second vertical hydraulic device 52 are vertically arranged on the top plate 50 respectively bottom of both ends; the first vertical hydraulic device 51 and the second vertical hydraulic device 52 are used to drive the top plate 50 to move a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com