Multi-layer rubber pipe resisting to lateral pressure

A technology for rubber tubes and lateral pressure resistance, which is applied in the field of rubber tubes. It can solve the problems of limited lateral pressure resistance and easy deformation, and achieve the effects of improving lateral pressure resistance, small bending radius, and enhancing longitudinal mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The examples listed in the present invention are only used to help understand the present invention, and should not be construed as limiting the scope of protection of the present invention. For those of ordinary skill in the art, without departing from the idea of the present invention, Improvements and modifications are made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

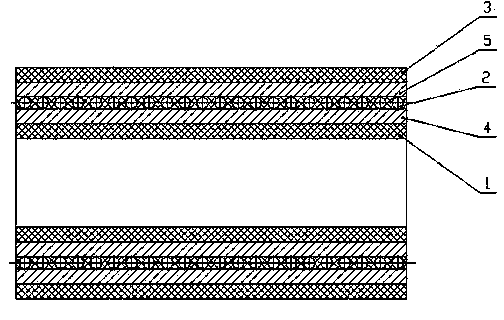

[0015] Such as figure 1 As shown, the present invention includes a pipe body. The pipe body has a multilayer structure and includes an inner rubber layer 1 arranged inside the pipe body. The inner rubber layer 1 is made of rubber or plastic material, which can be adjusted according to the internal medium of the pipe body. The material and thickness of the inner rubber layer 1 need to be selected and determined for the chemical and corrosive characteristics and chemical or mechanical seal to meet the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com