High-voltage ignition relay and operating method thereof

A high-voltage ignition and relay technology, applied in the direction of instruments, weapon accessories, electrical components, etc., can solve the problems that do not meet the requirements of high-voltage pyrotechnic explosion ignition, do not meet the safety requirements of weapon systems, and have no insurance agencies, etc., to achieve a good weapon system The effect of matching adaptive performance, improving anti-interference ability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

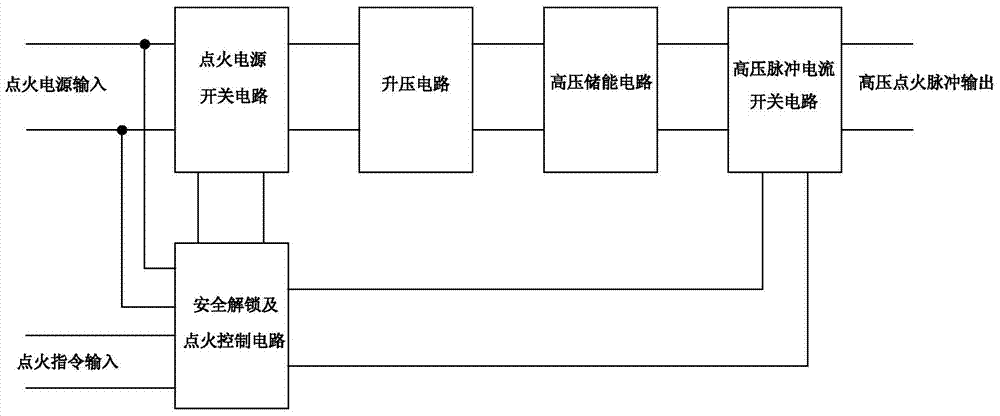

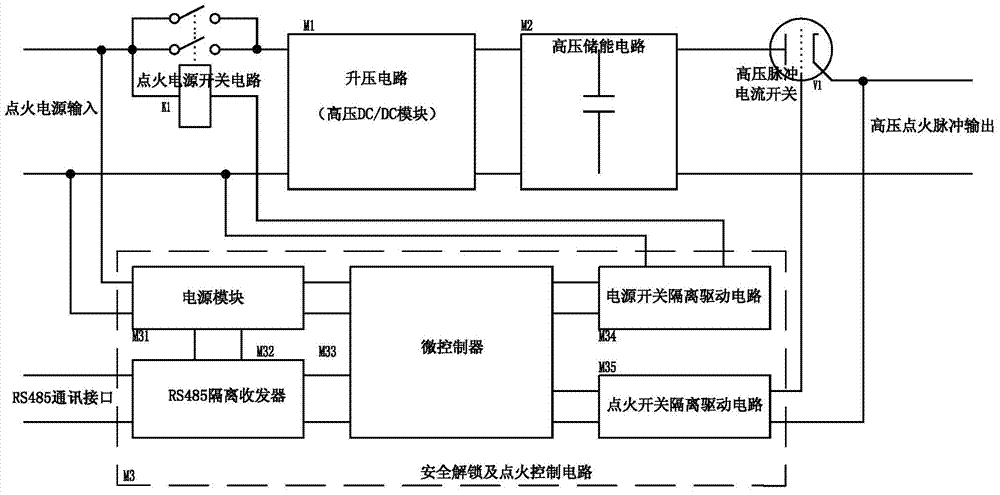

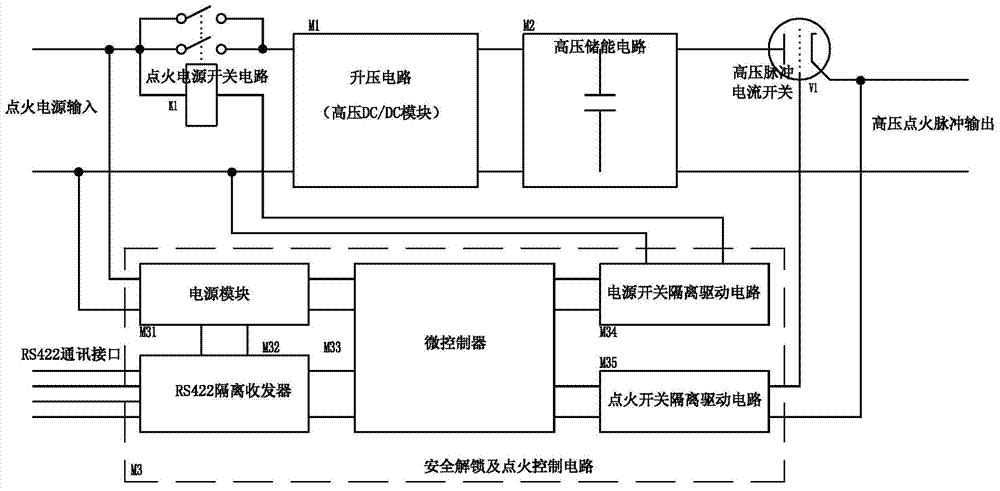

[0025] A high voltage ignition relay, such as figure 1 As shown, it is mainly composed of ignition power switch circuit, safety unlocking and ignition control circuit, boost circuit, high-voltage energy storage circuit, and high-voltage pulse current switch circuit. The input end of the ignition power switch circuit is connected with the external input signal of the ignition power supply. The output terminal of the ignition power switch circuit is connected with the input terminal of the boost circuit. The output end of the boost circuit is connected to the input end of the high voltage energy storage circuit. The output end of the high-voltage energy storage circuit is connected to the input end of the high-voltage pulse current switch circuit. The input end of the safety unlocking and ignition control circuit is connected to the ignition power input signal input from the outside, the control end of the safety unlocking and ignition control circuit is connected to the super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com