Part position accuracy detection device

A detection device and position degree technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems that the verticality of the detection rod cannot be guaranteed, the detection accuracy cannot be guaranteed, and the detection rod is easily damaged, so as to ensure the verticality , Improve the detection efficiency and ensure the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

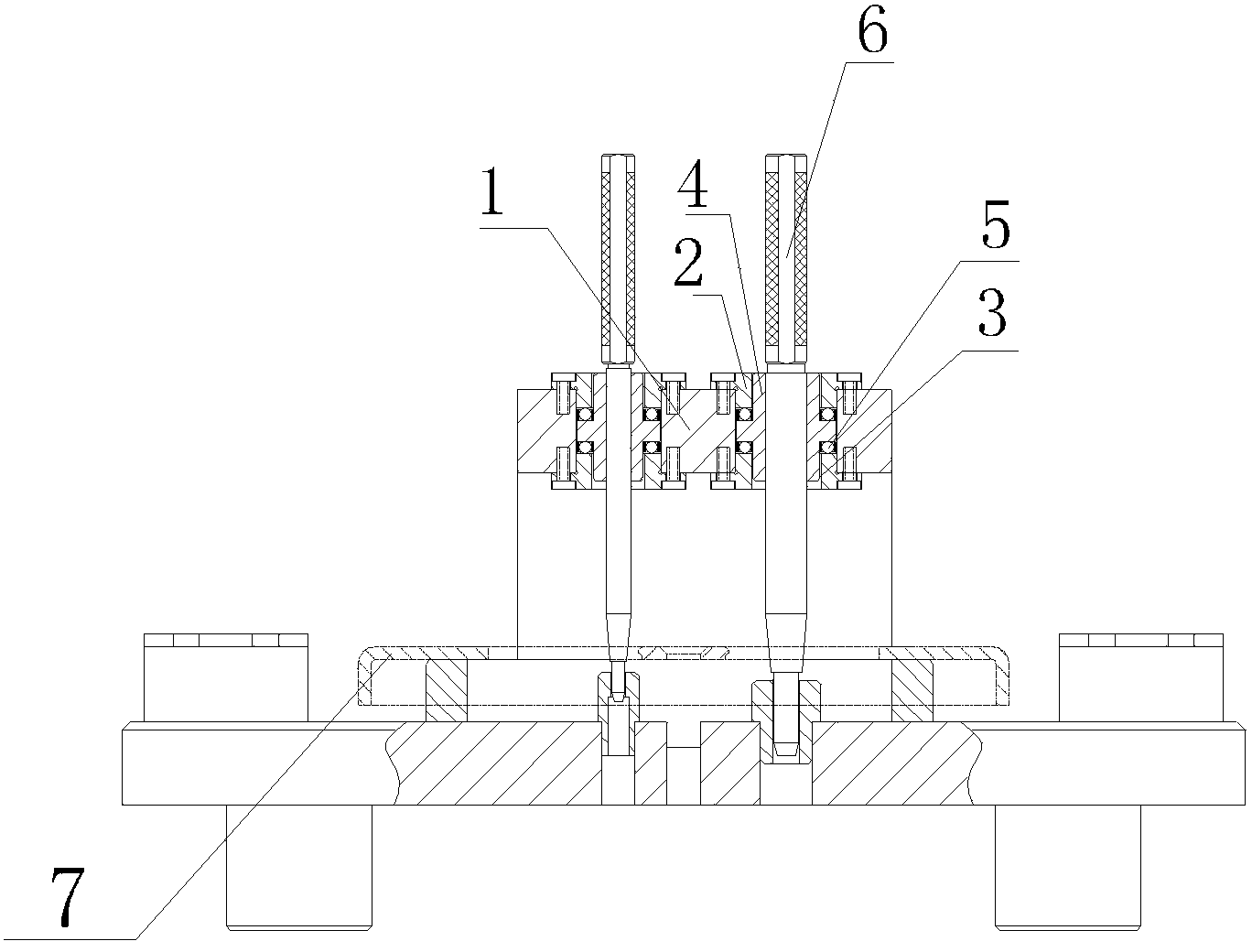

[0008] See figure 1 As shown, a part position detection device includes a detection frame 1, a cage 2 is arranged on the detection frame 1, a detection hole 3 is arranged on the cage 2, a positioning sleeve 4 is arranged in the detection hole 3, and a positioning sleeve 4 The cage 2 is connected by two circles of balls 5 , and the detection rod 6 is arranged in the positioning sleeve 4 .

[0009] The positioned workpiece 7 detects the position of the hole on the workpiece through the detection rod 6 on the detection frame 1. The detection rod 6 is set on the detection frame 1 through the cage 2 and the positioning sleeve 4. At the same time, the detection rod 6 is accompanied by the positioning sleeve 4 Relying on the ball 5 to realize the rotation ensures the verticality of the detection rod 6, effectively avoids the damage of the detection rod, ensures the detection accuracy, and improves the detection efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com