Hole coaxiality detection device of automobile brake system clamp body

An automobile braking and coaxiality technology, which is applied to the field of inner hole coaxiality detection devices, can solve the problems of high production defect rate, high production defect rate and low production efficiency of brake calipers, so as to reduce the processing defect rate and improve production efficiency. The effect of improving detection efficiency and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the examples.

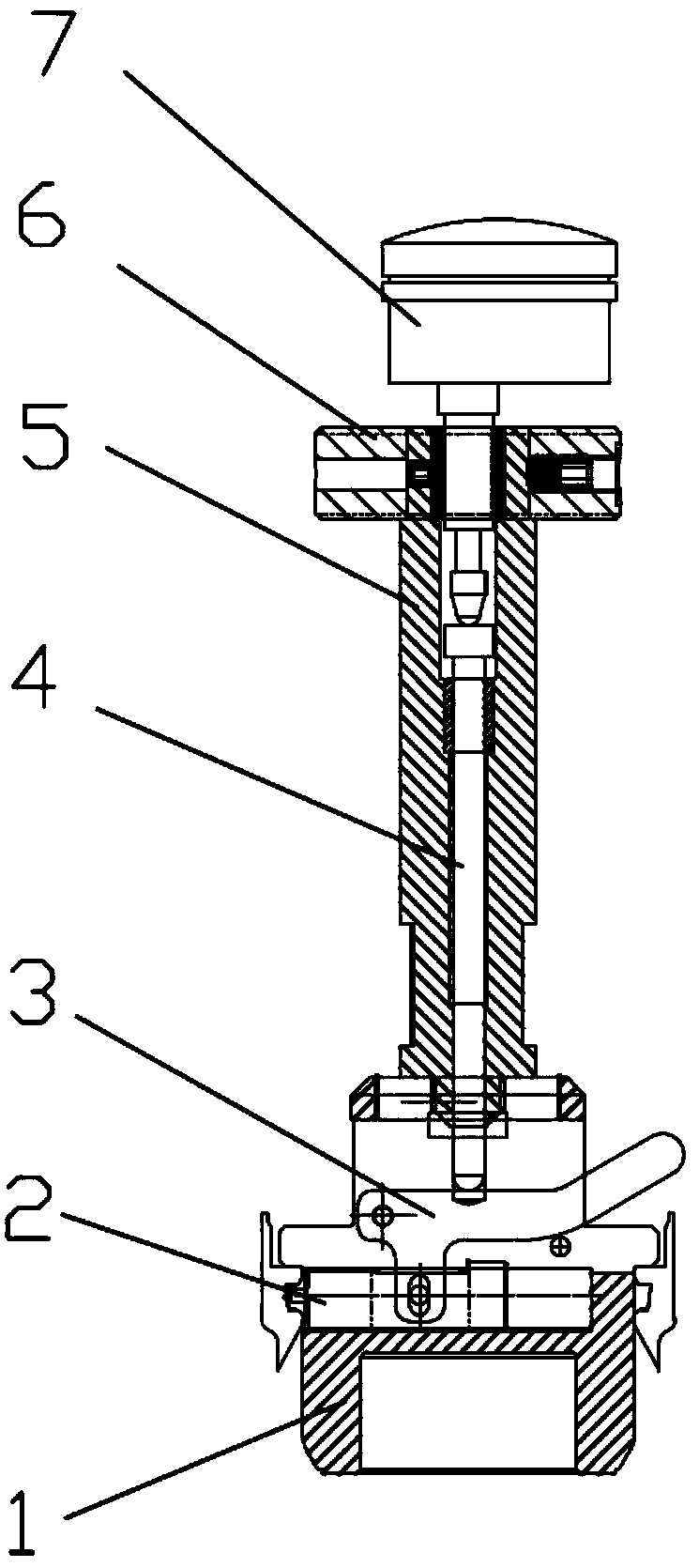

[0012] A device for checking coaxiality of caliper body holes of an automobile brake system, comprising a positioning shaft 1, a detection head 2, a crank arm 3, a transmission shaft 4, a support shaft 5, an adjustment knob 6, and a dial gauge 7. The positioning axis 1 is completely consistent with the reference holes of the two parts to be tested, and the detection head 2 is in contact with the inner diameter of the detected hole. expressed in form. Rotate the support shaft 5, and read the maximum value in one rotation, which is the eccentricity of the measured hole.

[0013] When testing, first insert the positioning shaft 1 into the reference hole of the tested part, align the testing head 2 with the inner wall of the tested hole, and make them match completely; rotate the adjusting knob 6 to reset the dial gauge 7 to zero; then rotate the support Axis 5, observe and record ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com