Patents

Literature

32results about How to "Reduce processing defect rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible display substrate, manufacturing method thereof and display device

ActiveCN109887416AReduce processing defect rateImprove adhesionFinal product manufacturePhotovoltaic energy generationSignal routingDisplay device

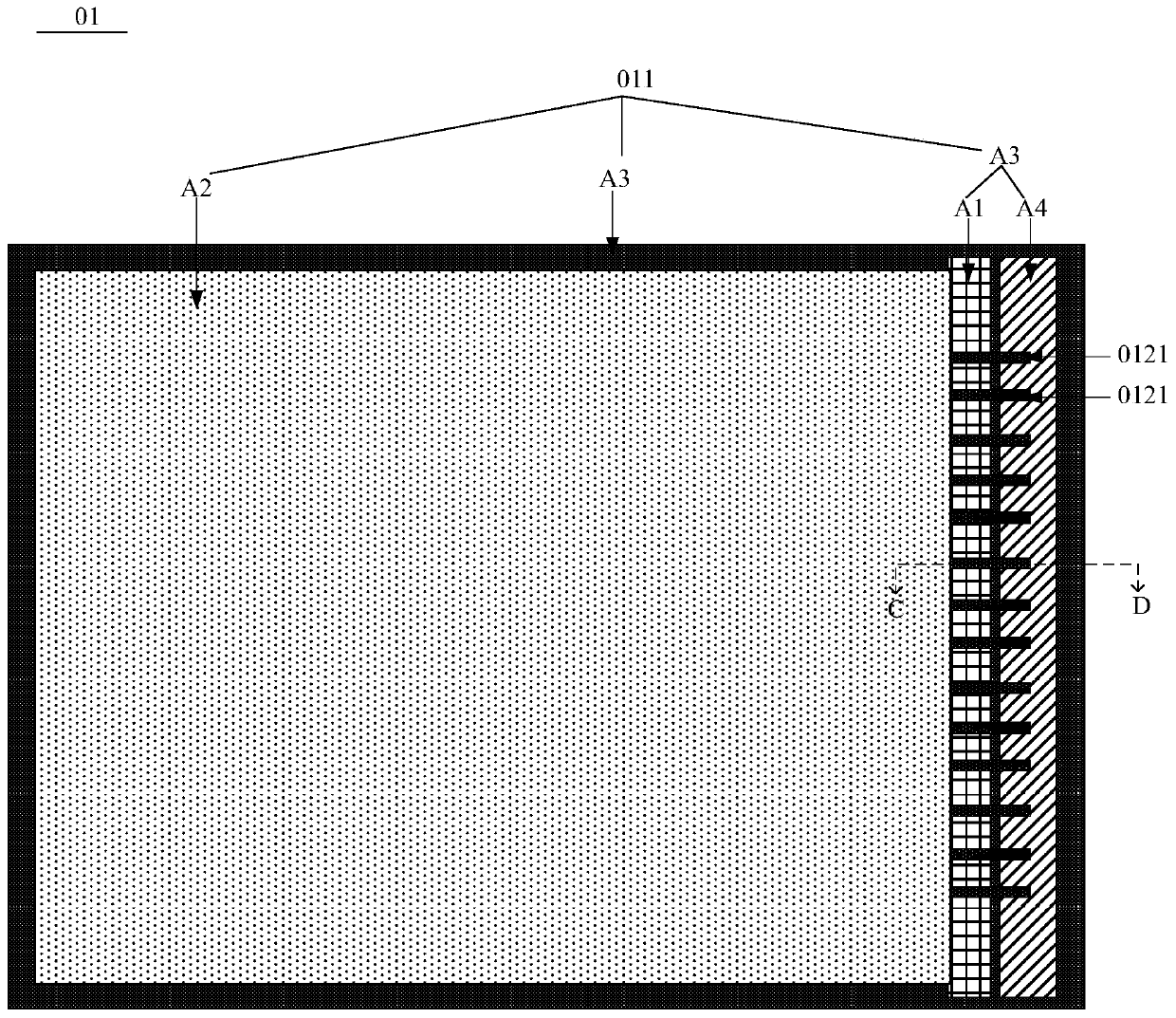

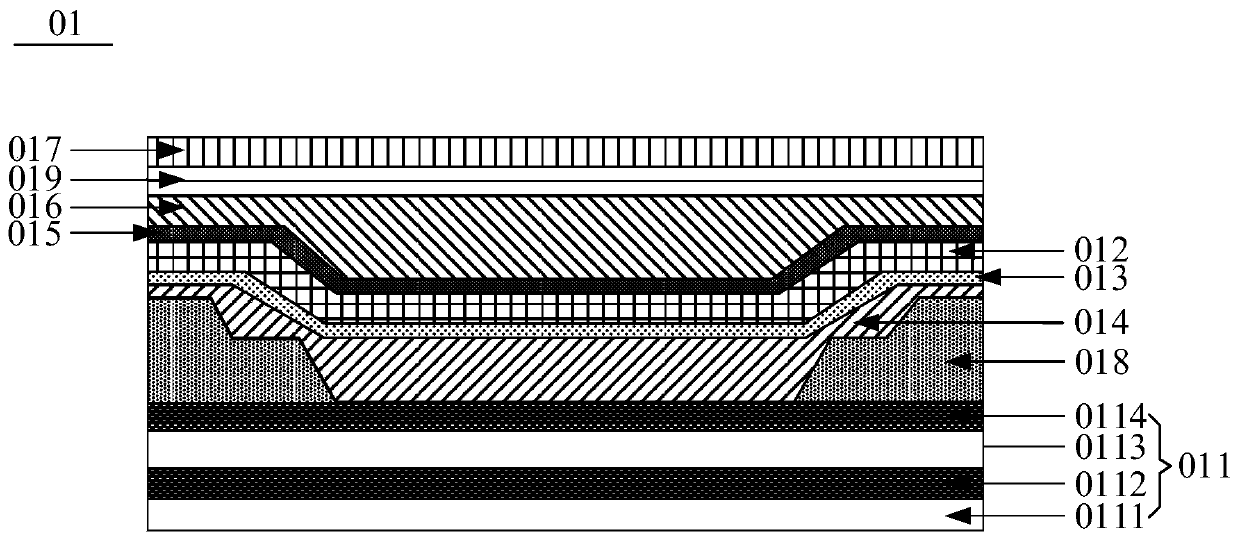

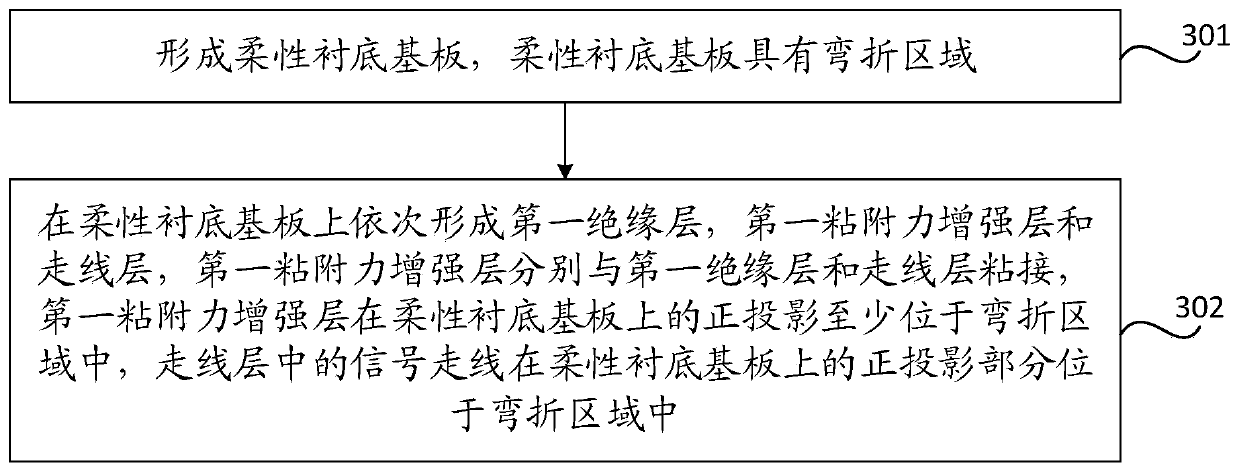

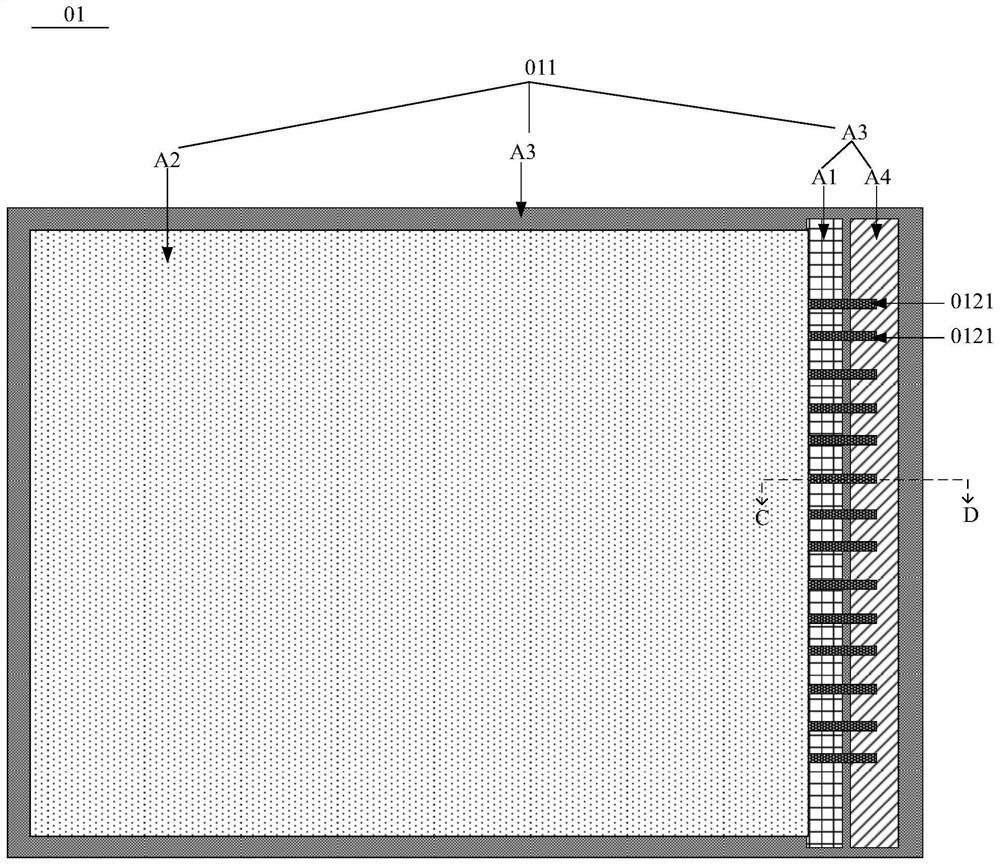

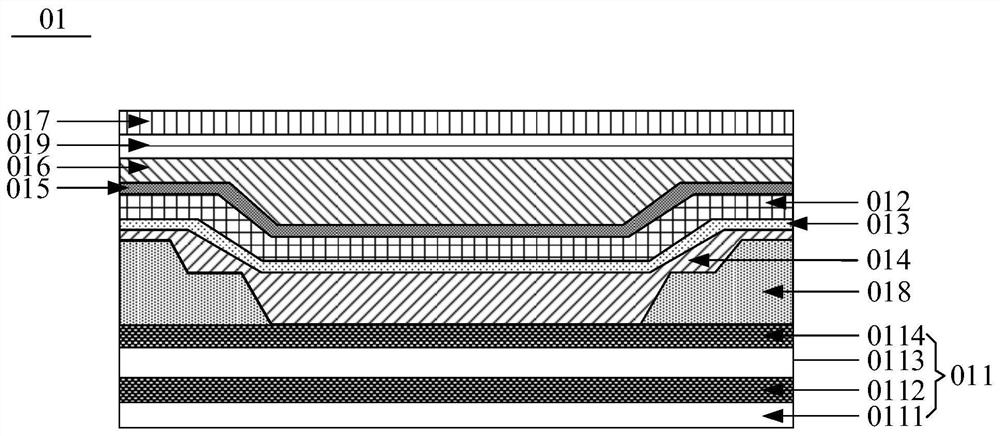

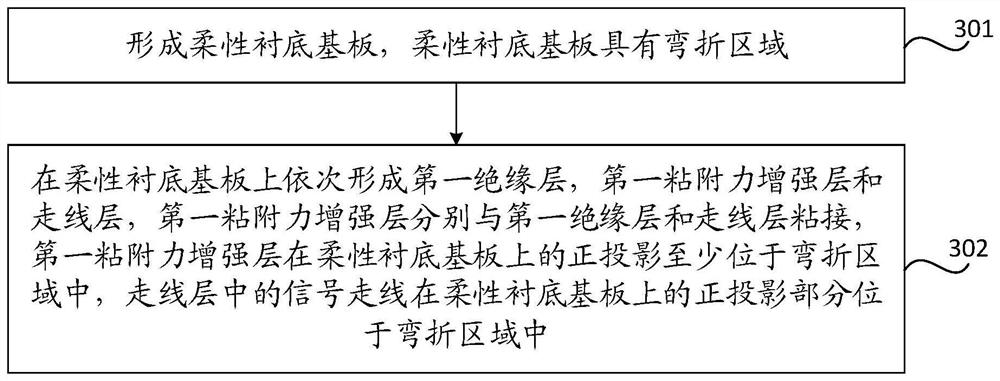

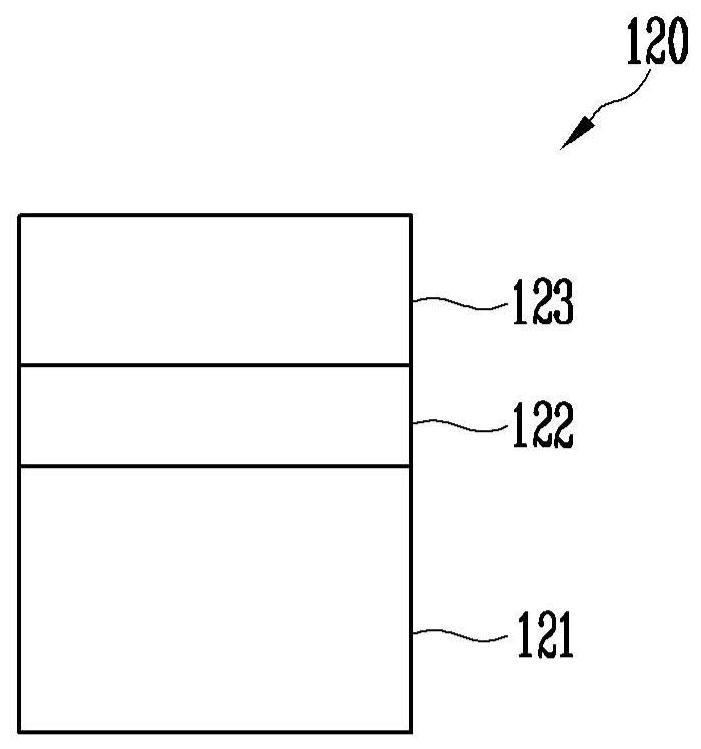

The invention relates to a flexible display substrate, a manufacturing method thereof and a display device, and belongs to the technical field of display. The flexible display substrate comprises: a flexible substrate, a routing layer, a first adhesion enhancement layer and a first insulating layer, wherein the routing layer, the first adhesion enhancement layer and the first insulating layer arelaminated on the flexible substrate; the first insulating layer is positioned on one side of the routing layer; the first adhesion enhancement layer is positioned between the first insulating layer and the routing layer; the first adhesion enhancement layer is respectively bonded with the first insulating layer and the routing layer; the flexible substrate is provided with a bending area; an orthographic projection of the first adhesion enhancement layer is at least positioned in the bending area of the flexible substrate; the orthographic projection of a signal routing in the routing layer ispartially positioned in the bending area of the flexible substrate; the first adhesion enhancement layer is used for enhancing the adhesion between the routing layer and the first insulating layer. The flexible display substrate is used for preventing signal wiring of the routing layer of the flexible display substrate from being broken.

Owner:BOE TECH GRP CO LTD

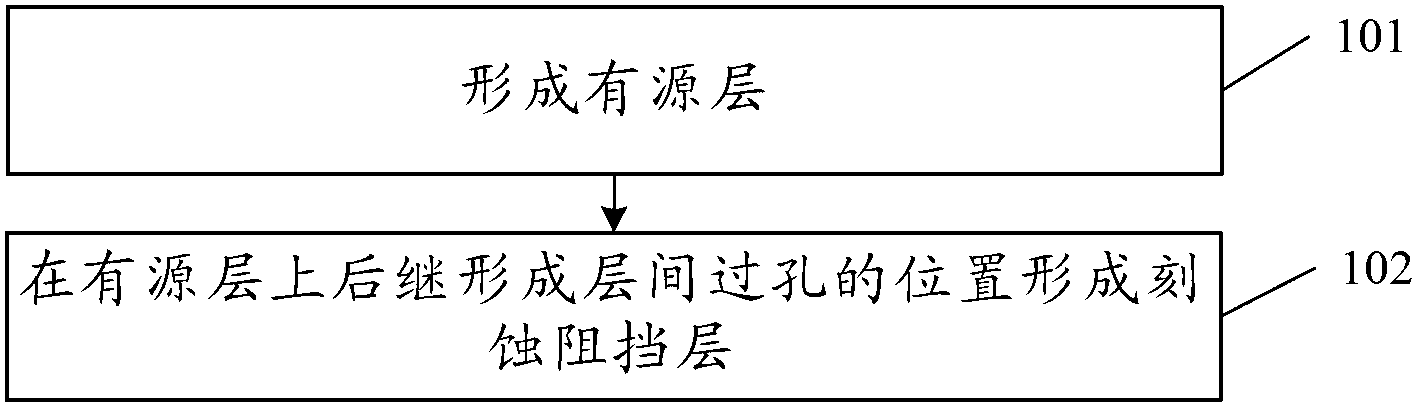

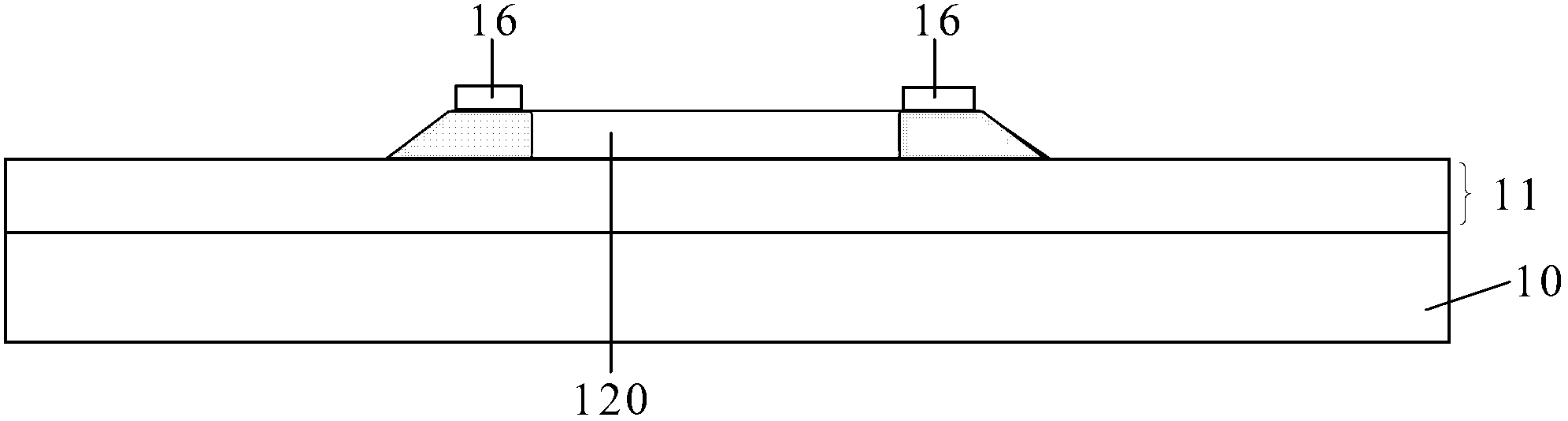

Thin film transistor, manufacturing method of thin film transistor, array substrate and display device

InactiveCN103258745AProtect from being etchedReduce processing defect rateTransistorSemiconductor/solid-state device manufacturingEtchingDisplay device

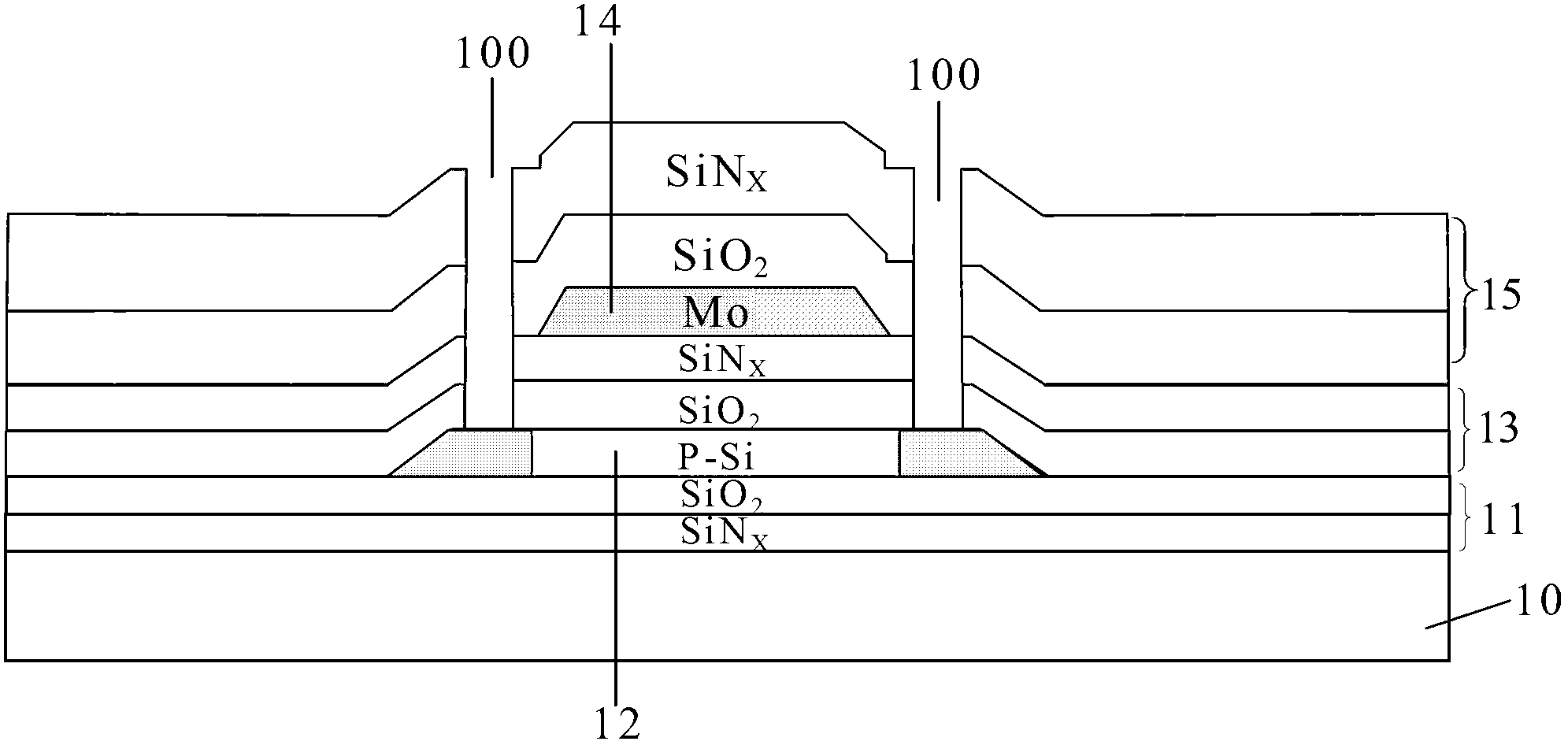

The invention discloses a thin film transistor, a manufacturing method of the thin film transistor and a display device, and relates to the field of display. The problems of uneven etching, incomplete etching, over-etching and the like during interlayer through hole forming are resolved and technology reject ratio is lowered. The manufacturing method of the array substrate comprises the steps of forming an active layer, and after the active layer is formed, forming an etching blocking layer at the position, where an interlayer through hole is formed subsequently, on the active layer to protect the active layer during the process of etching the interlayer through hole. The active layer is connected with a source and a leakage electrode through the interlayer through hole.

Owner:BOE TECH GRP CO LTD

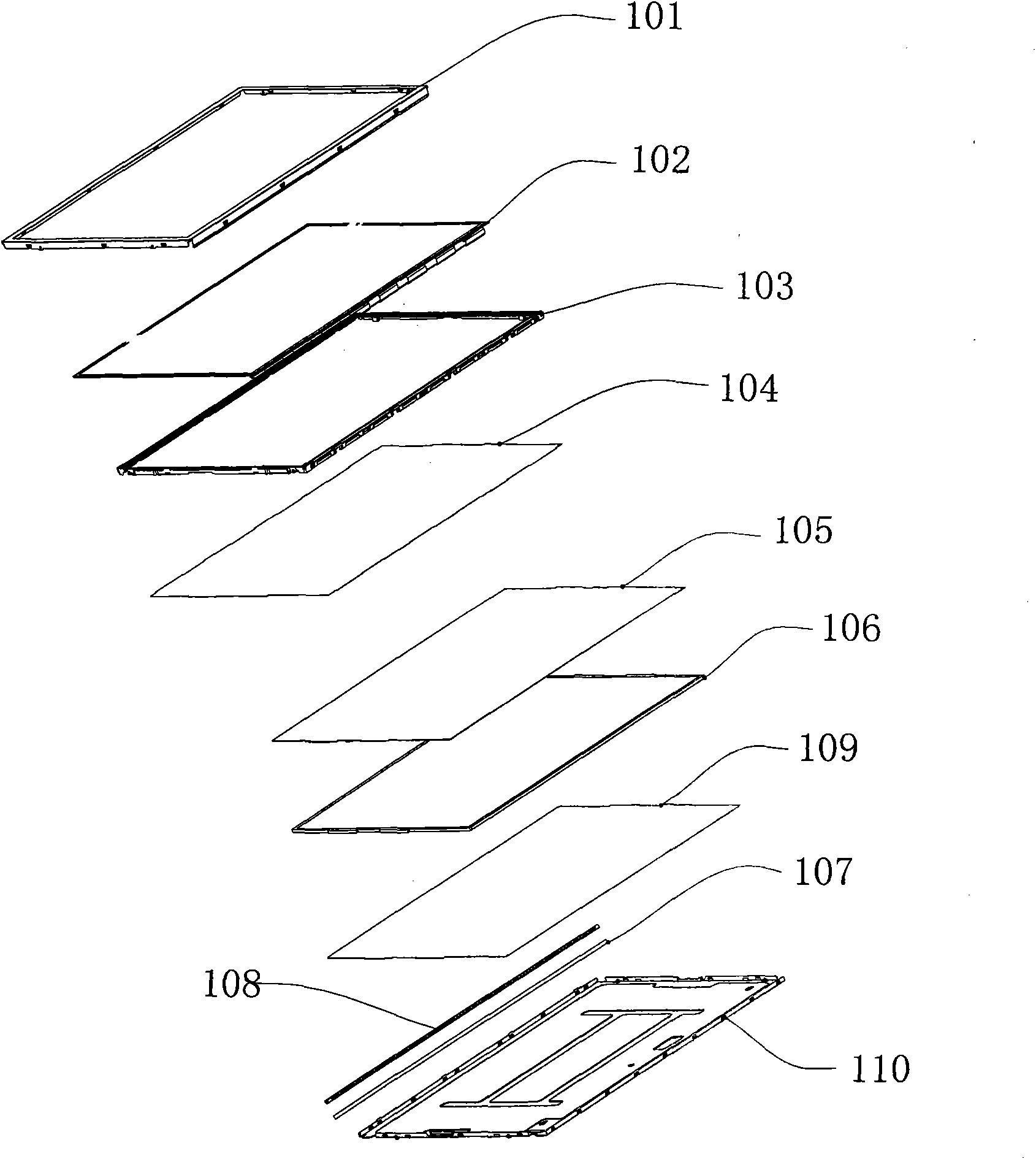

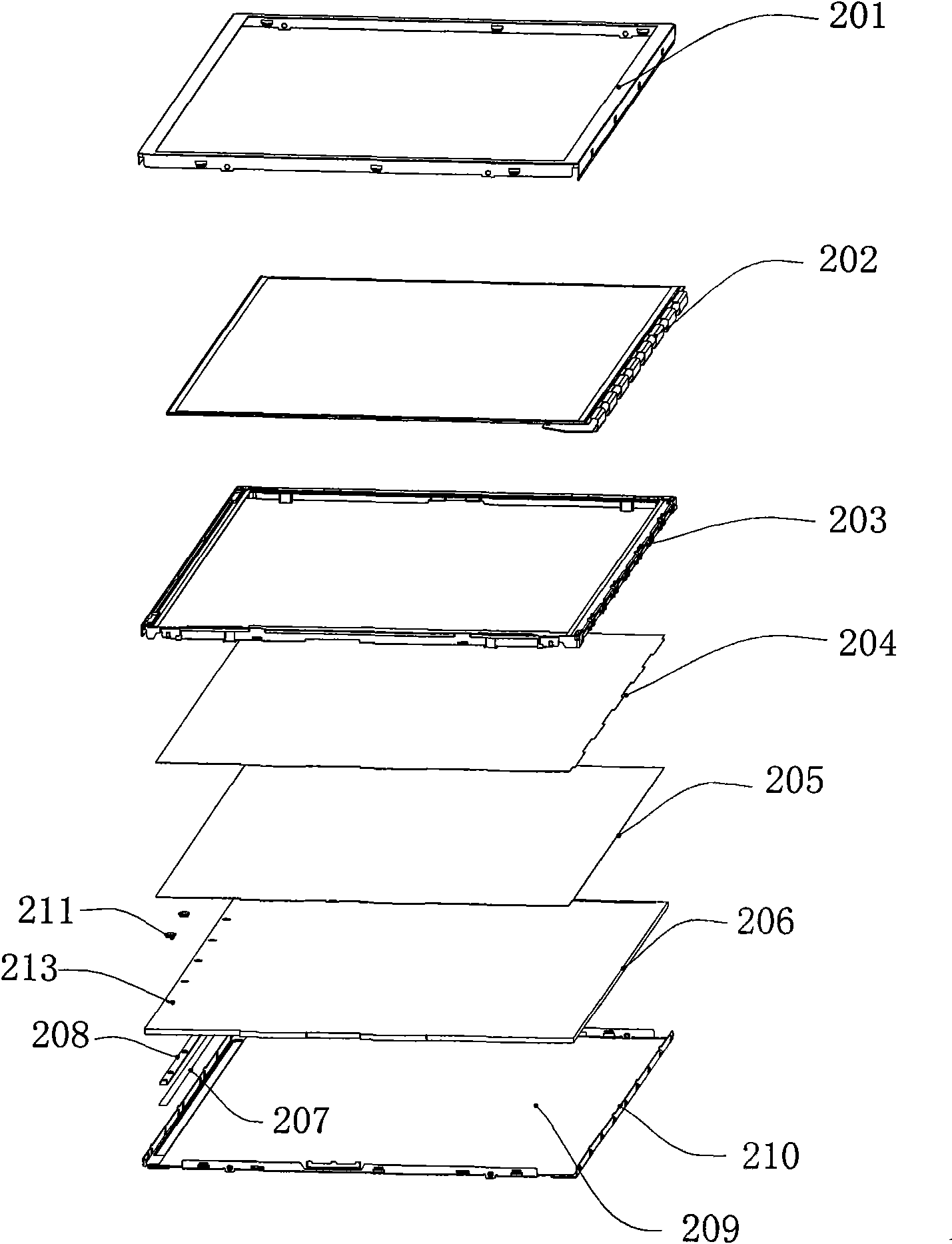

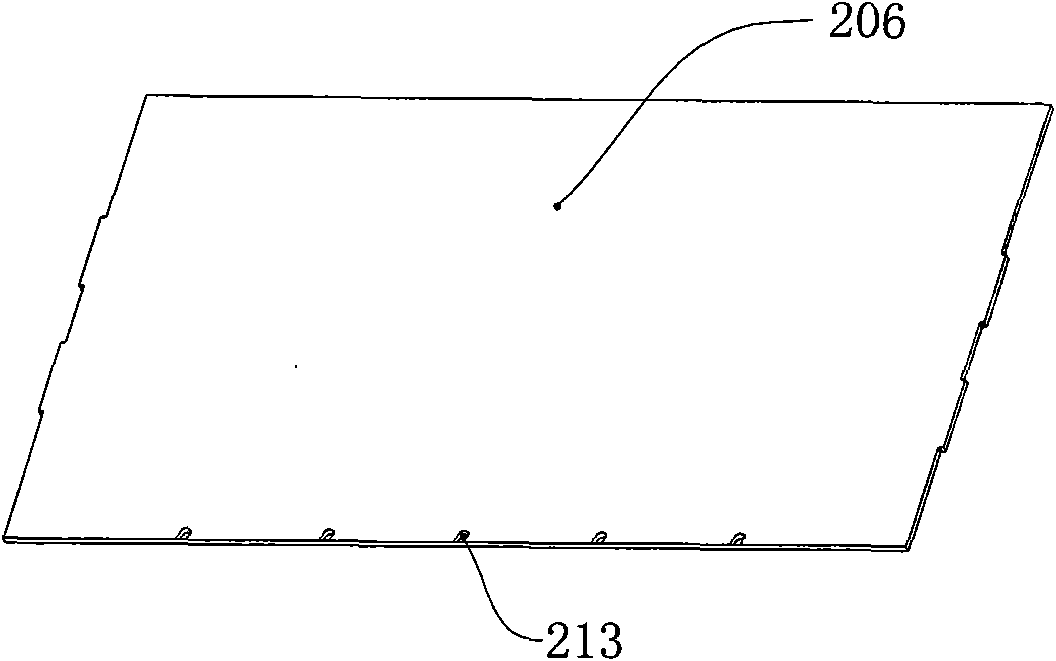

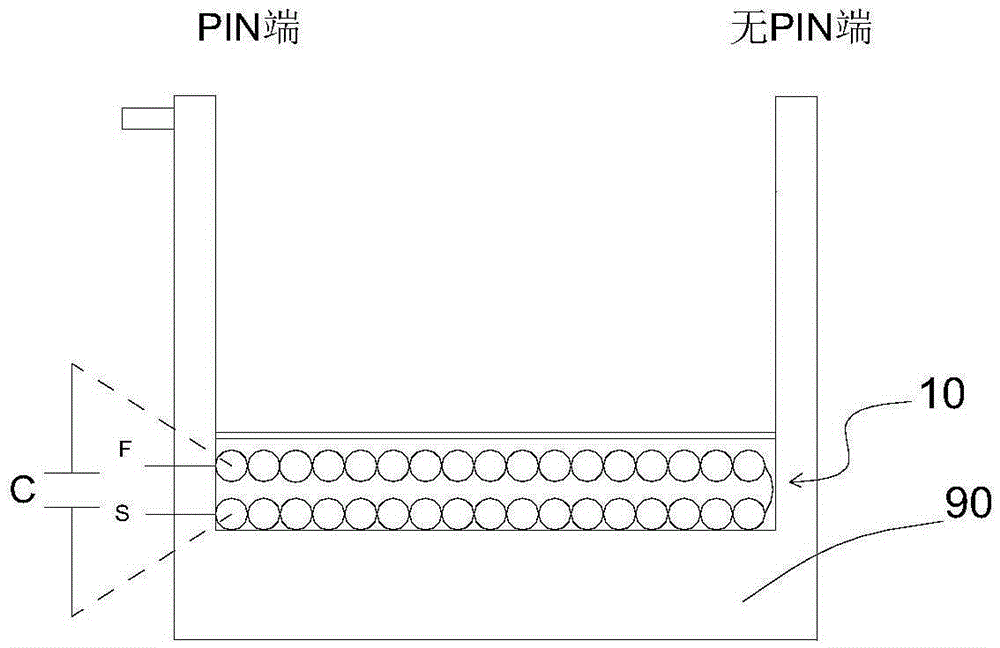

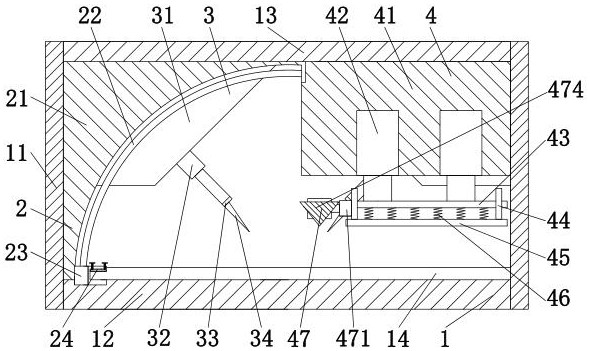

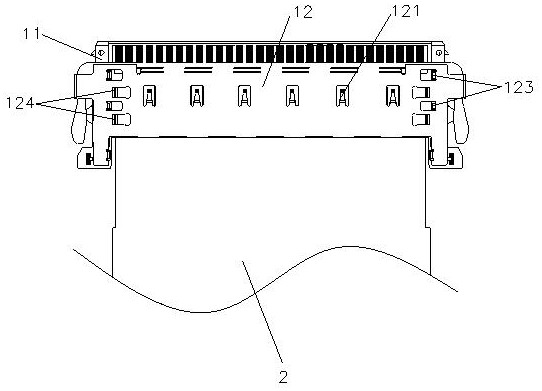

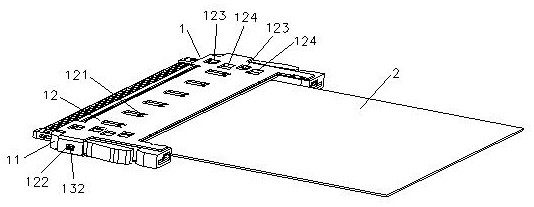

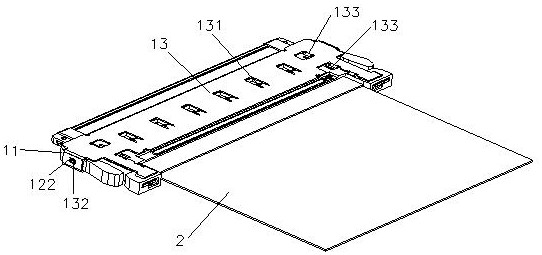

LED liquid crystal display backlight module

InactiveCN102022680AIncrease brightnessImprove reliabilityPoint-like light sourceLight fasteningsLiquid-crystal displayLight guide

The invention discloses an LED liquid crystal display backlight module which can provide the possibility of higher brightness under the condition of not increasing spotlighting sheets, and the structure of the LED liquid crystal display backlight module can be suitable for high-power LED lamps to reduce the application of low-power LED lamps so as to reduce the probability of faults. The LED liquid crystal display backlight module comprises an LED lamp strip and a light guide plate, wherein the LED lamp strip is provided with an LED lamp; the back surface of the light guide plate is provided with the LED lamp strip; the light guide plate corresponding to the position of the LED lamp is provided with a hole; the hole comprises two orifices positioned on the front surface and the back surface of the light guide plate; the orifice positioned on the back surface of the light guide plate is provided with a direct type LED lamp; and the orifice positioned on the front surface of the light guide plate is provided with a light-reflecting device used for reflecting the light of the LED lamp. The invention is mainly used for LED backlight sources of a liquid crystal display and a liquid crystal television.

Owner:HKC CORP LTD

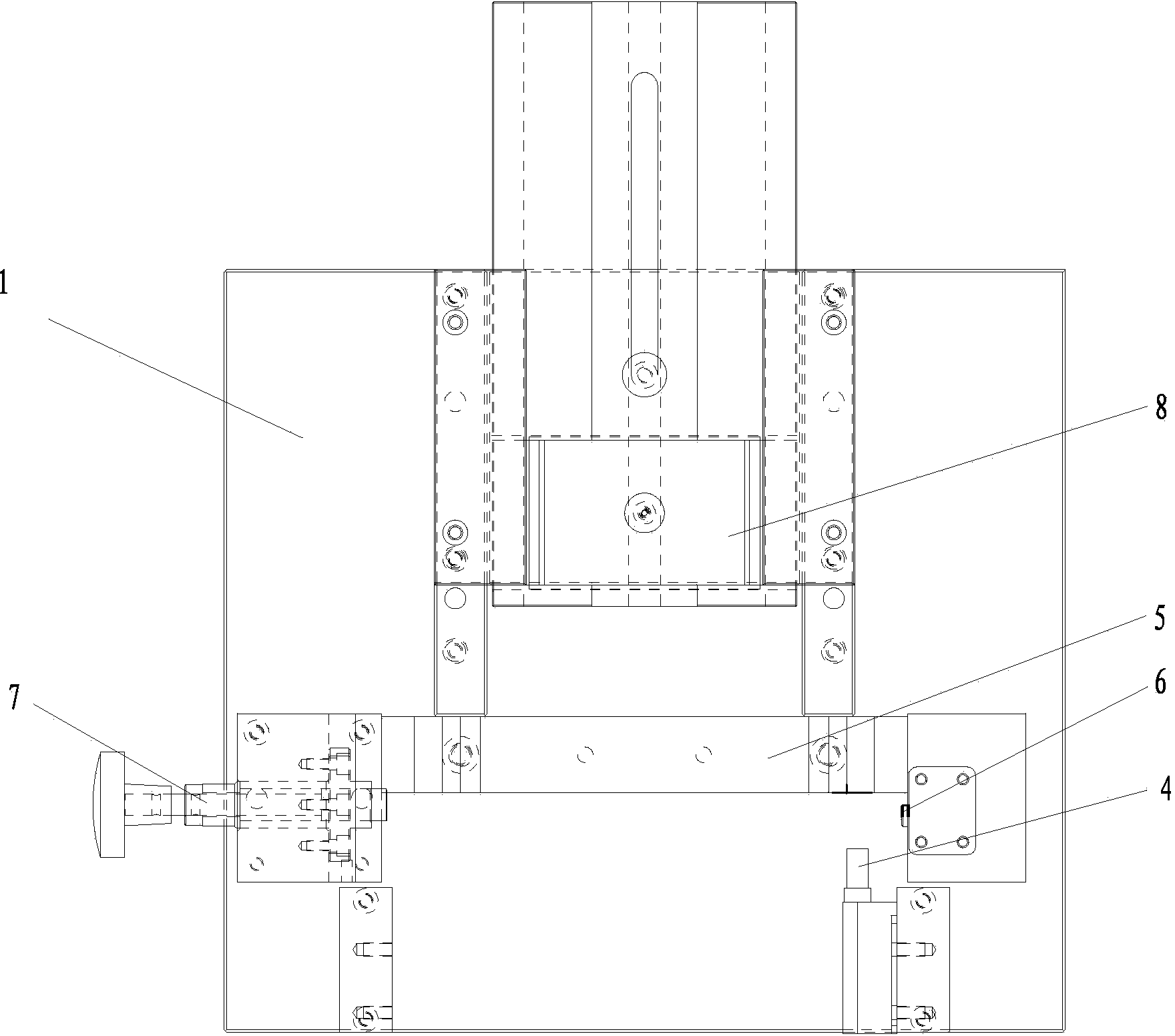

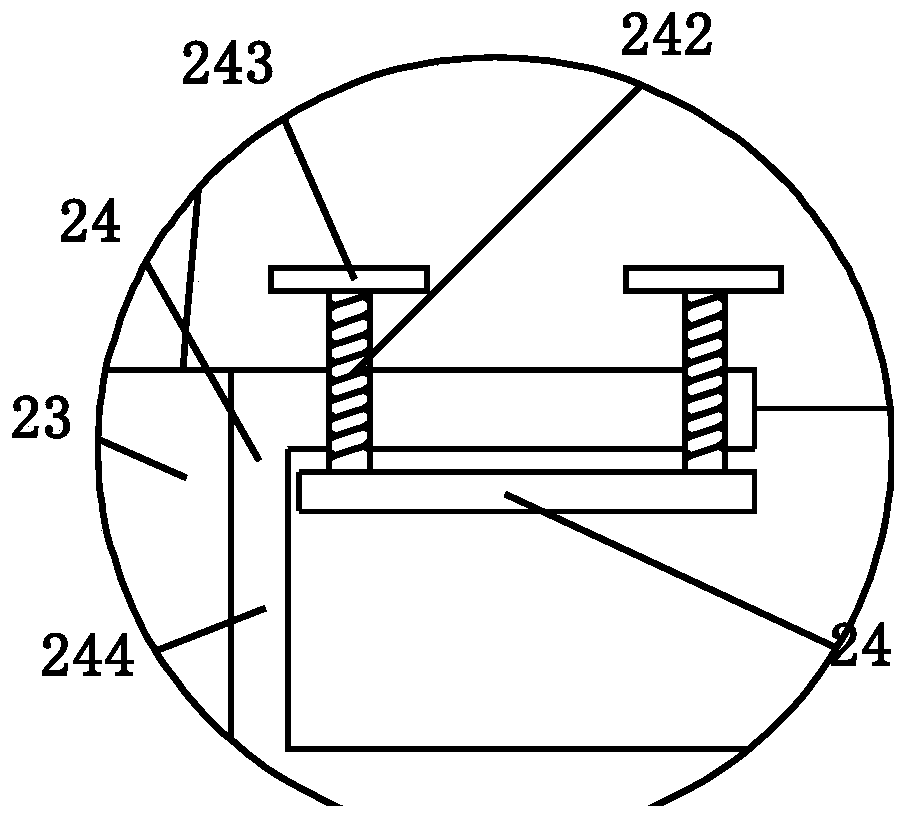

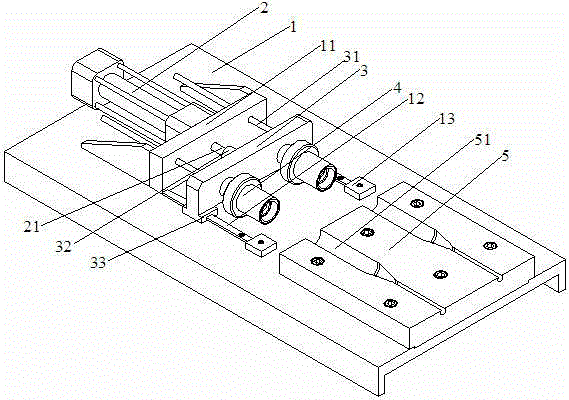

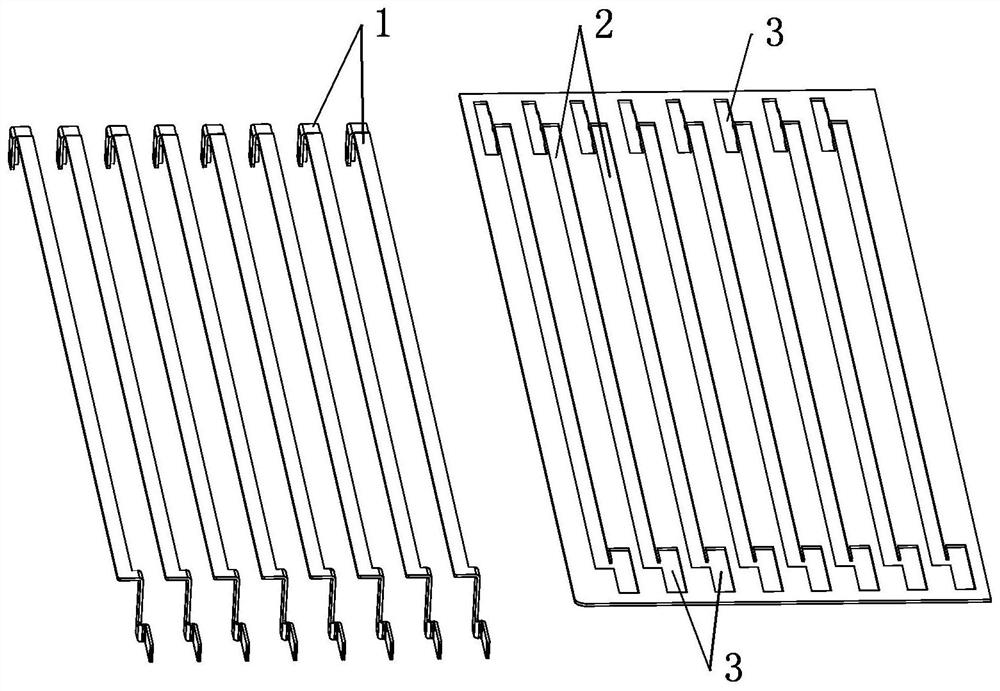

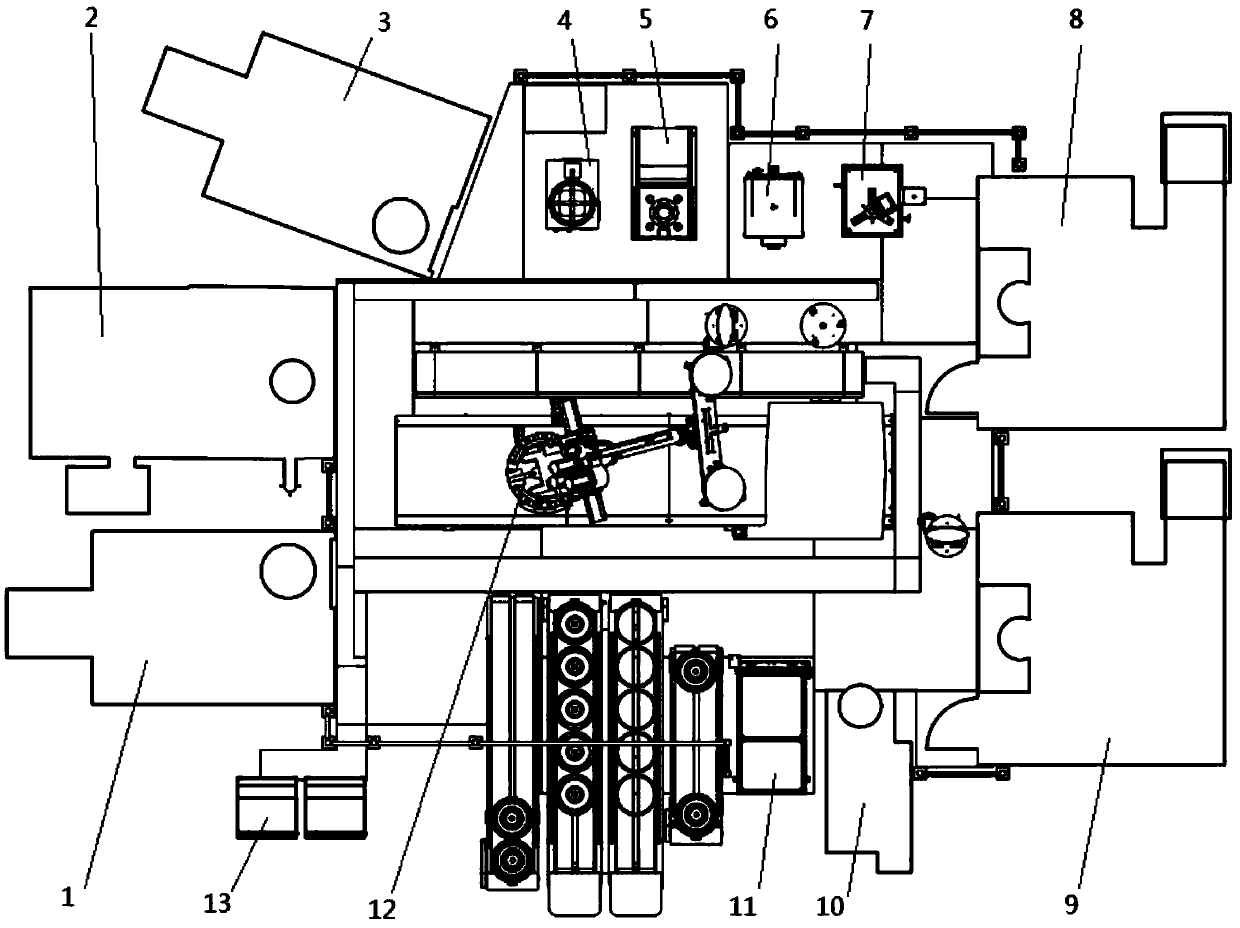

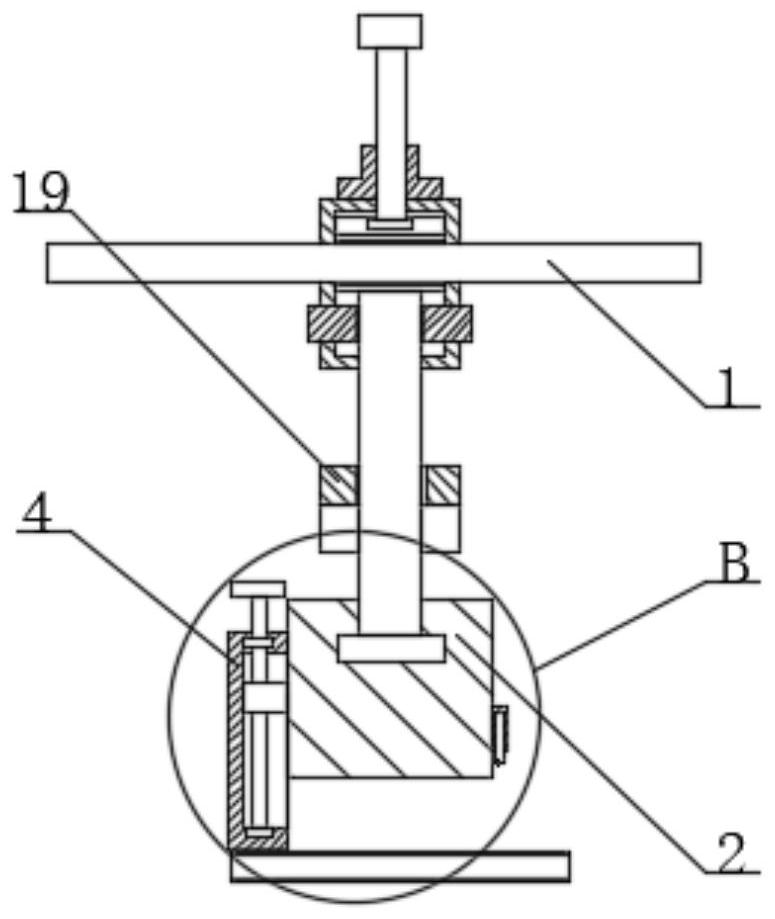

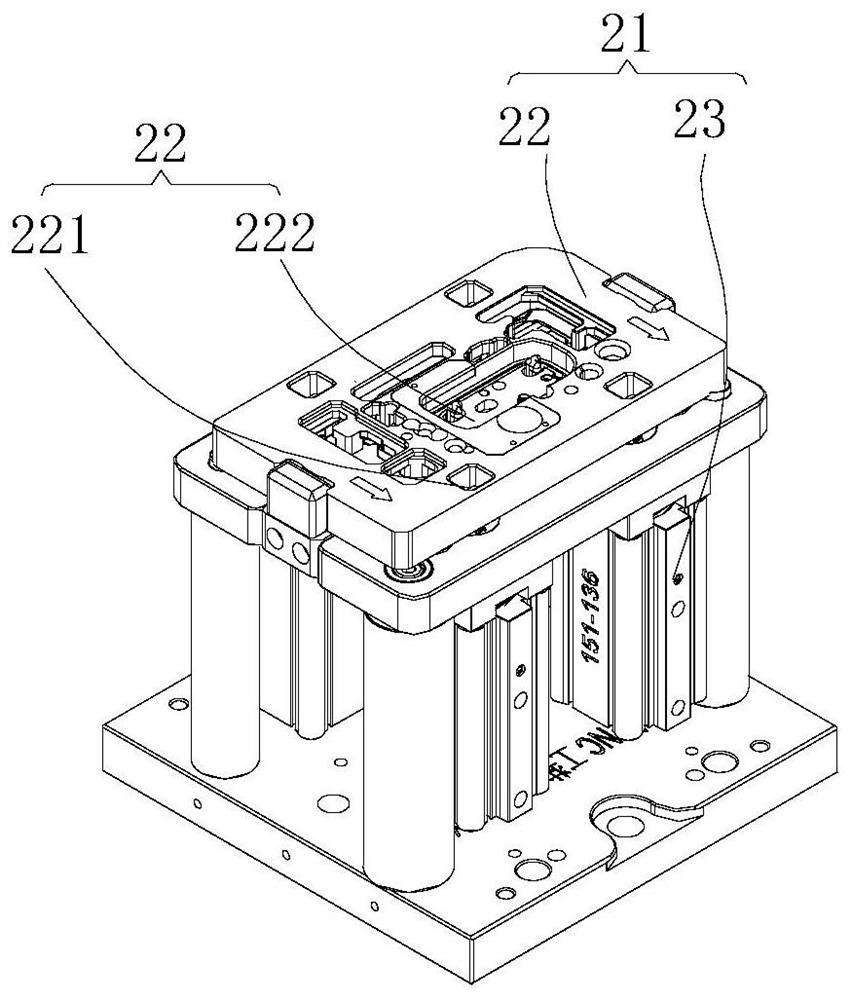

Fixture device for special-shaped groove of automobile brake system support

InactiveCN103630035AImprove production inspection efficiencyReduce processing defect rateMechanical measuring arrangementsEngineeringAbnormal shaped

A fixture device for a special-shaped groove of an automobile brake system support comprises a clamping positioning part and a detection part. The clamping positioning part comprises a base plate (1), vertical plates (2), a positioning plate (5), a Y-direction positioning column (6), a Z-direction positioning column (4), pressure pliers (3) and a Y-direction jacking pin (7). The detection part comprises a detection block (8). The base plate (1) is provided with the Z-direction positioning column (4), and the vertical plates (2) are provided with the Y-direction positioning column (6), the positioning plate (5) and the pressure pliers (3). By the arrangement, degree of freedom of a to-be-detected work piece is limited on three directions and fixed through the Y-direction jacking pin (7) and the pressure pliers (3), the special-shaped trough of the work piece is judged whether to be qualified or not by allowing the detection block (8) to slide in a position of a special-shaped trough of the work piece to determine pass check of the special-shaped trough. The special-shaped groove fixture device has the advantages of convenience in detection, accurate data and easiness in operation and the like, detection of the special-shaped groove of the automobile brake system support has actual using effect, production detection efficiency of the automobile brake system support is greatly improved, and defective rate in processing the automobile brake system support is greatly reduced.

Owner:大久制作(大连)有限公司

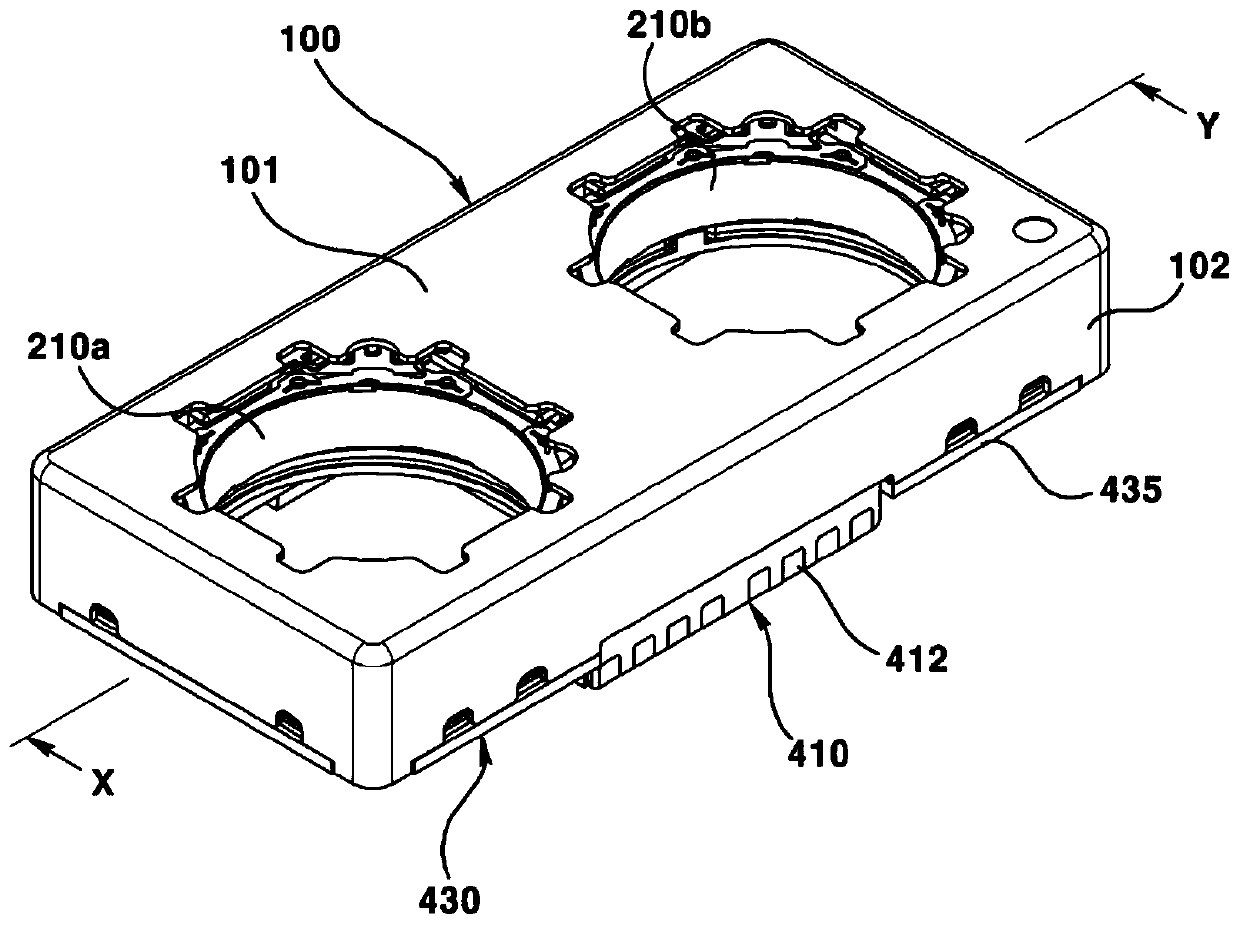

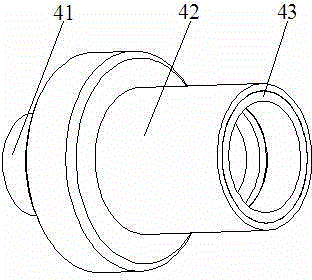

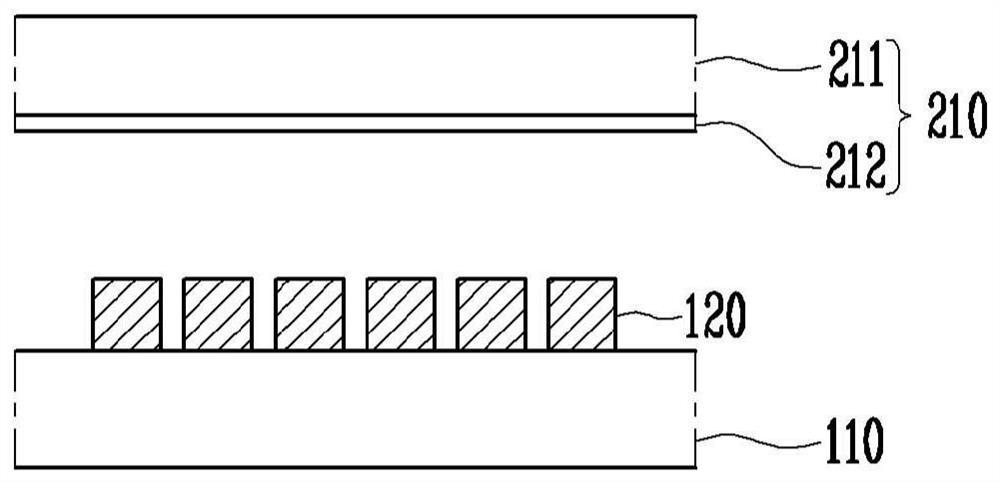

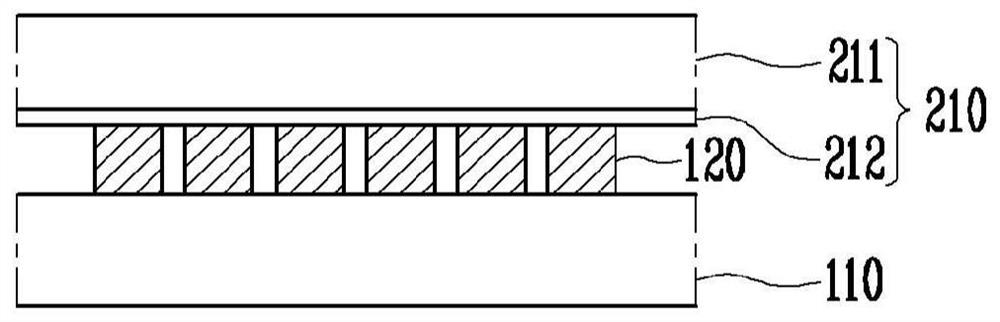

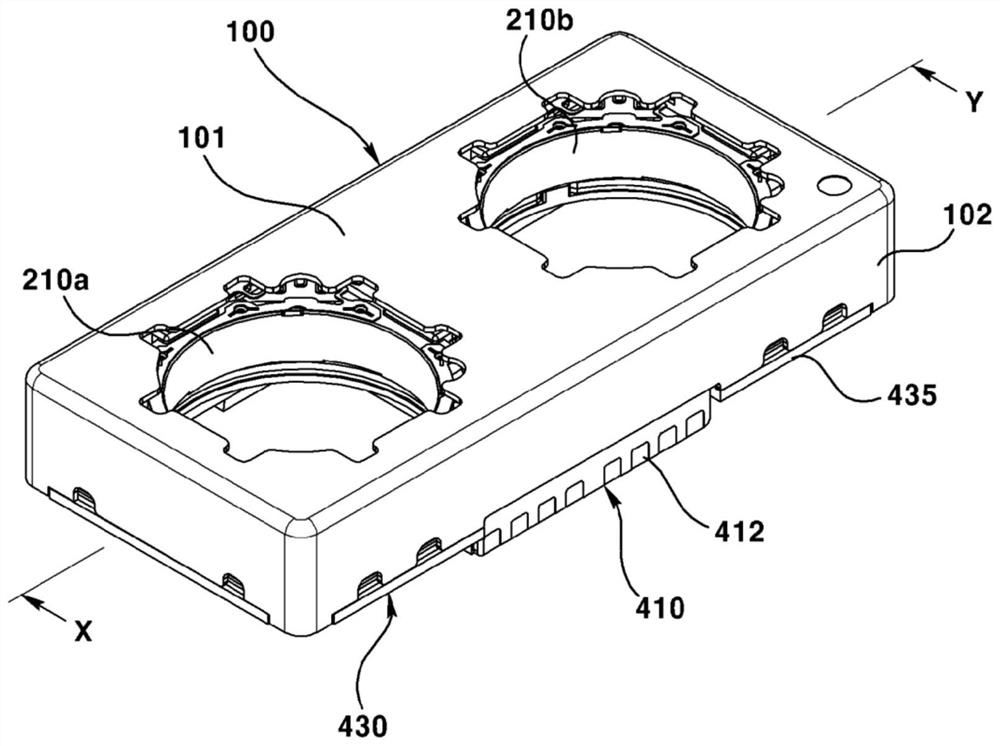

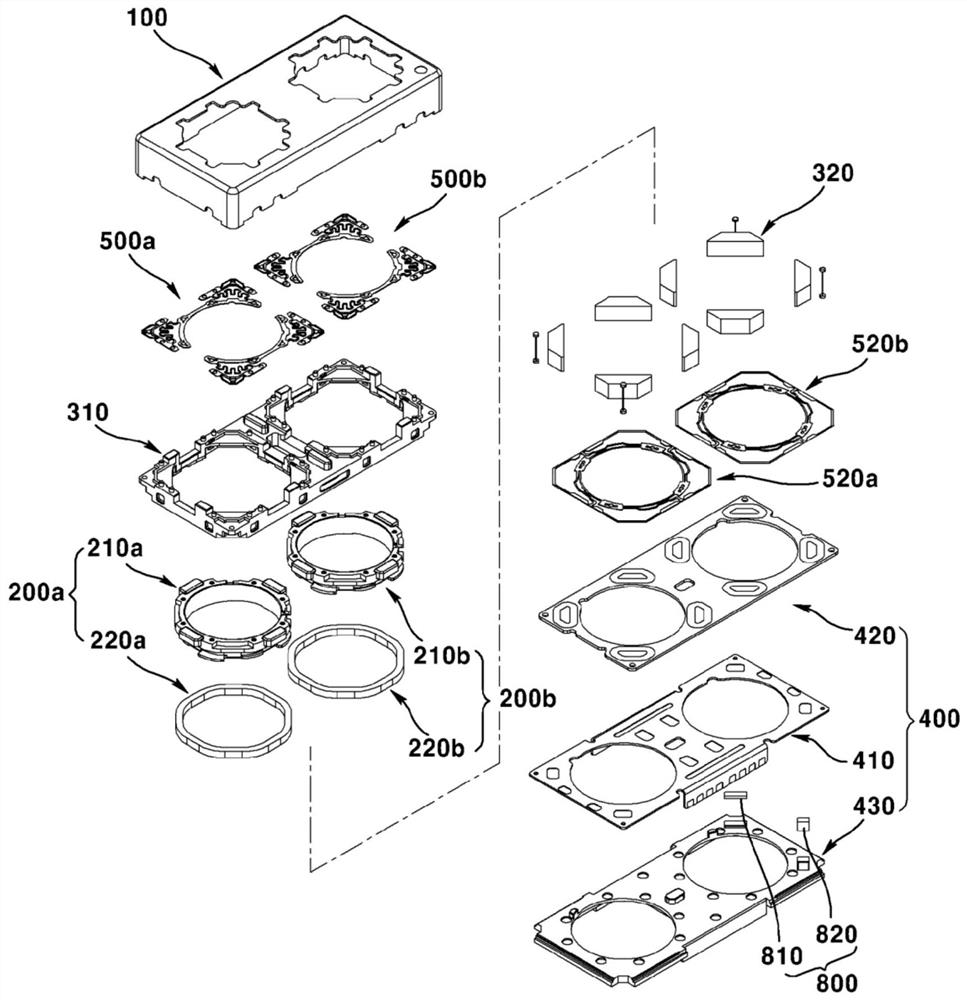

Dual lens drive device, dual camera module, and optical device

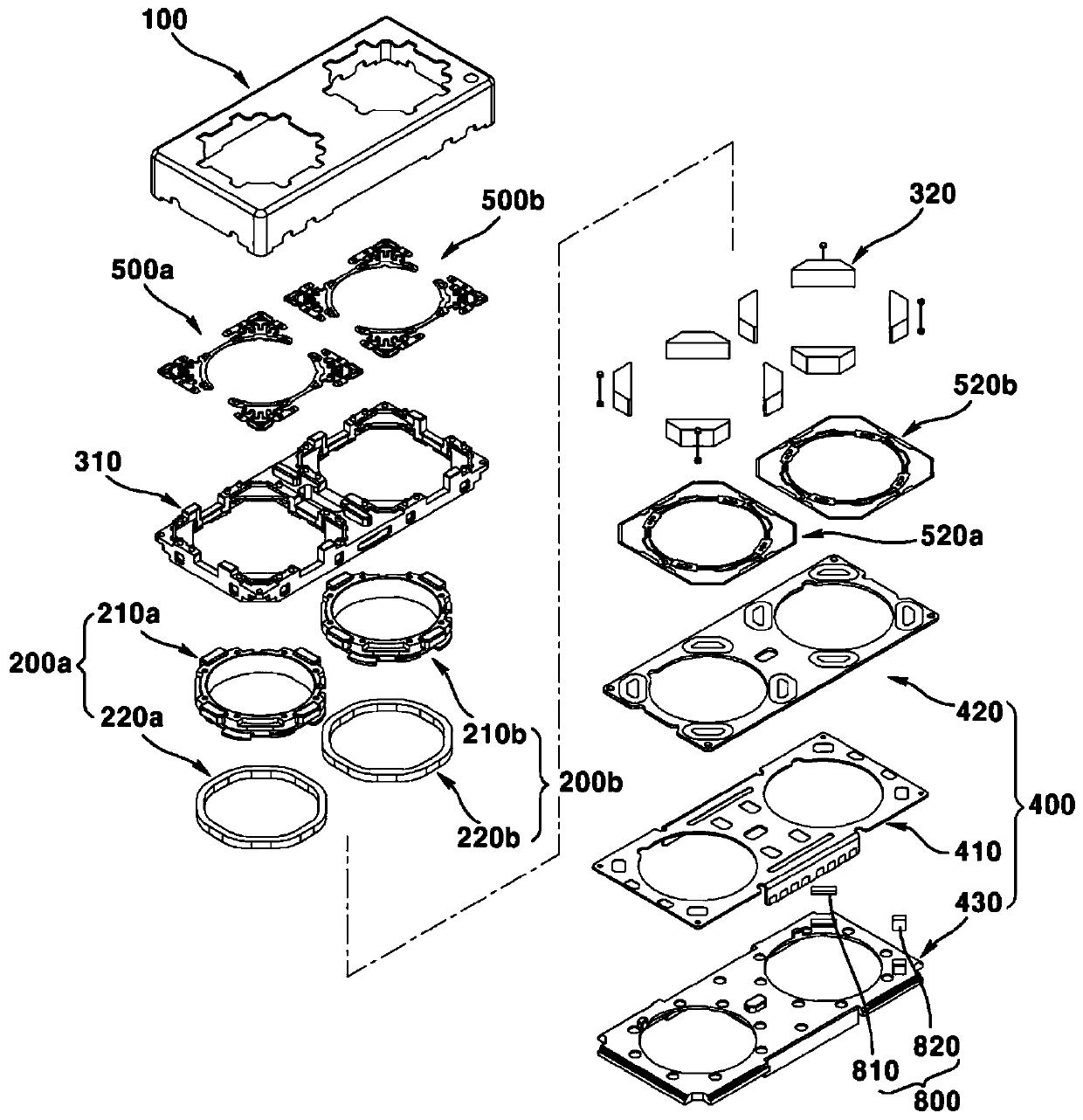

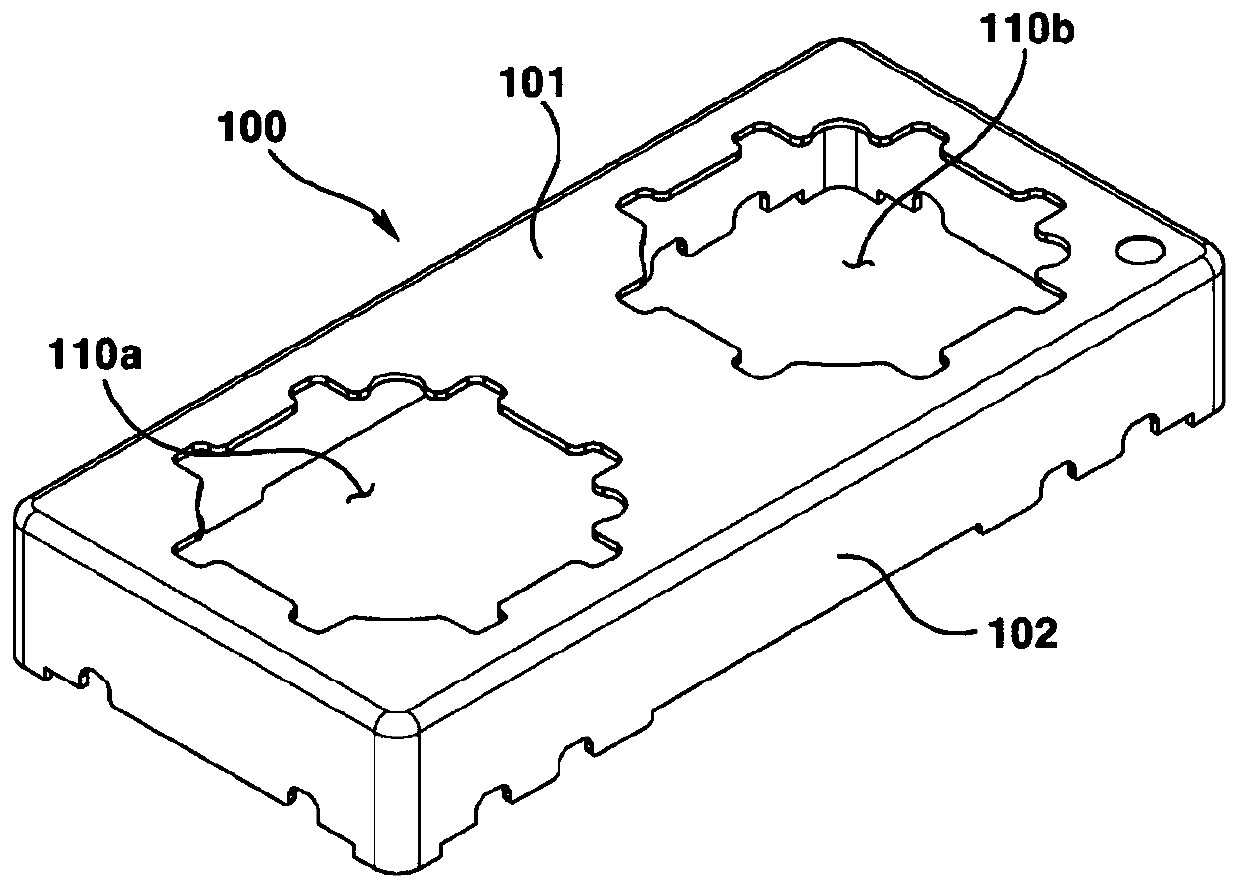

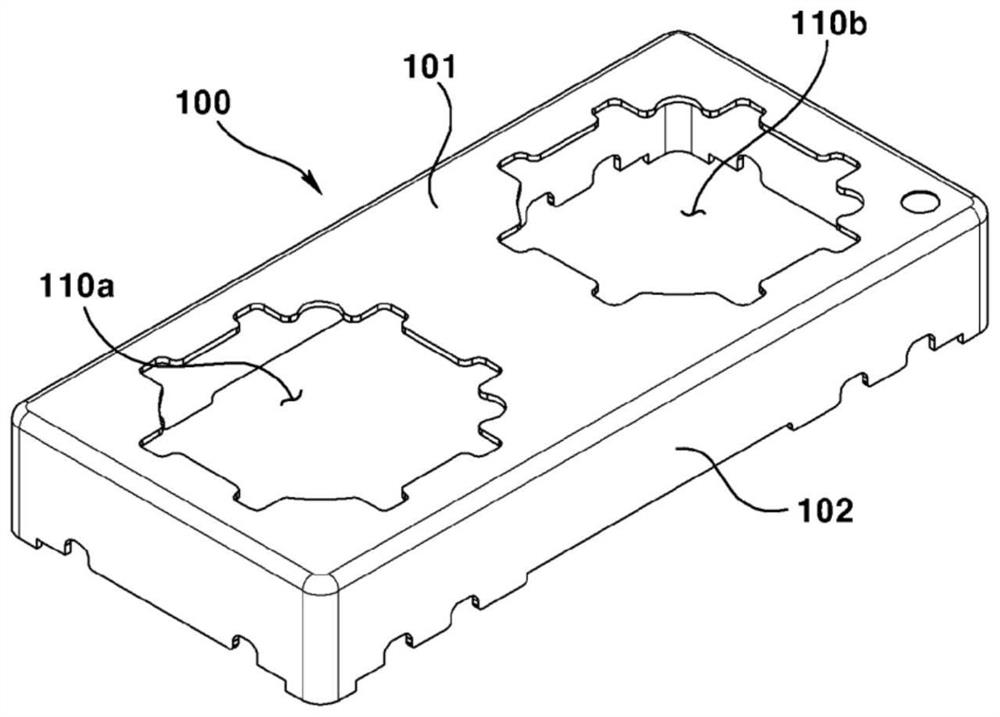

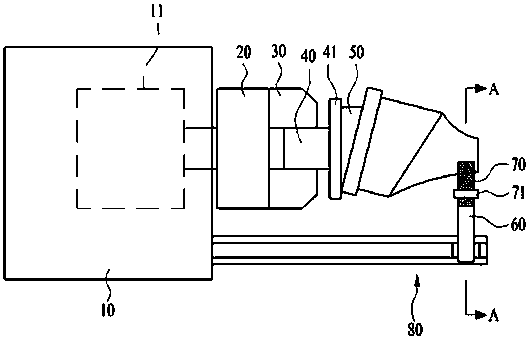

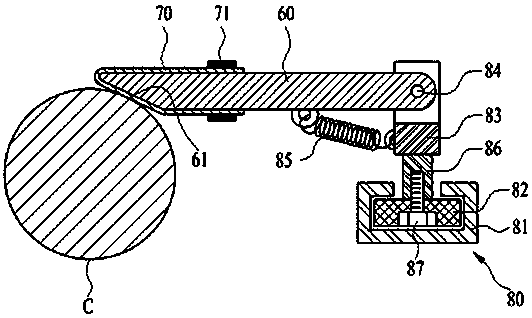

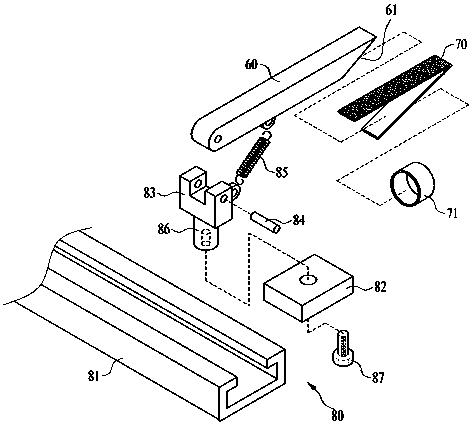

ActiveCN110169048AConvenience guaranteedReduce processing defect rateTelevision system detailsPrintersBobbinEngineering

The present embodiment relates to a dual lens drive device that comprises: a housing; a first bobbin which is disposed to move in a first direction inside the housing; a second bobbin which is disposed to move in the first direction inside the housing and is spaced apart from the first bobbin; a first coil which is disposed on the first bobbin; a second coil which is disposed on the second bobbin;a magnet which is disposed in the housing and faces the first coil and the second coil; a base which is disposed below the housing; a substrate which comprises a circuit member having a third coil disposed to face the magnet between the housing and the base; and a support member which movably supports the housing with respect to the substrate, wherein the housing is integrally formed.

Owner:LG INNOTEK CO LTD

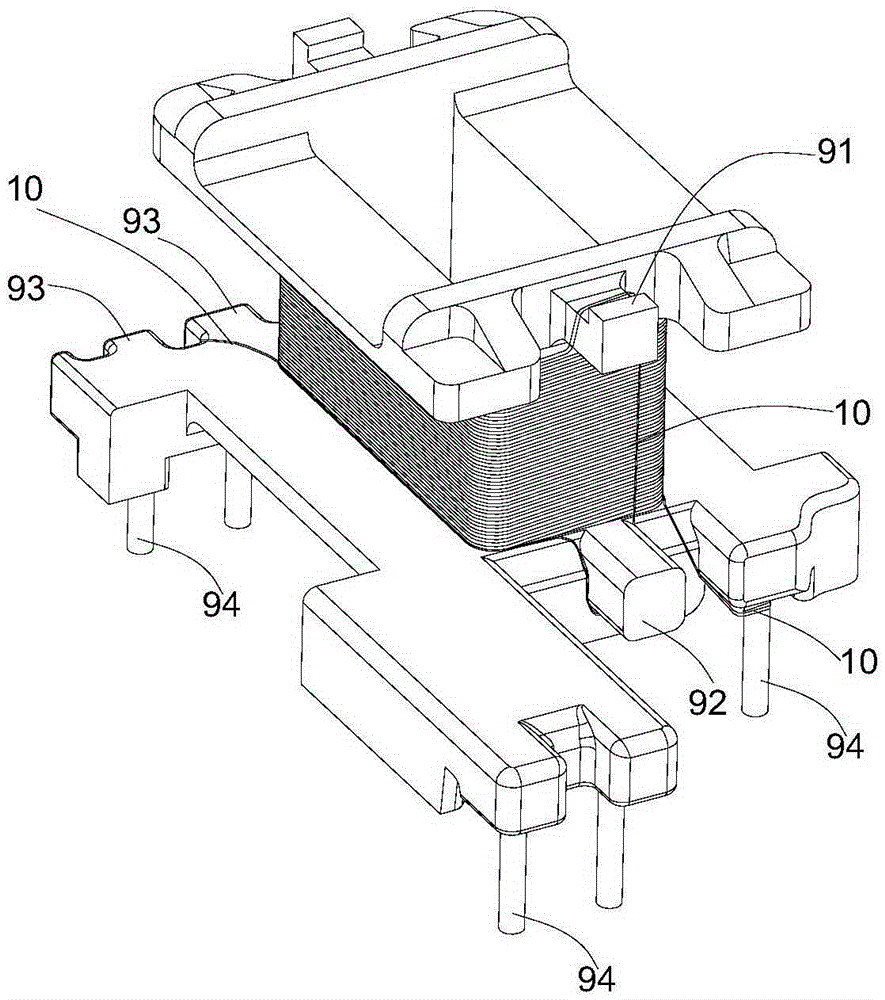

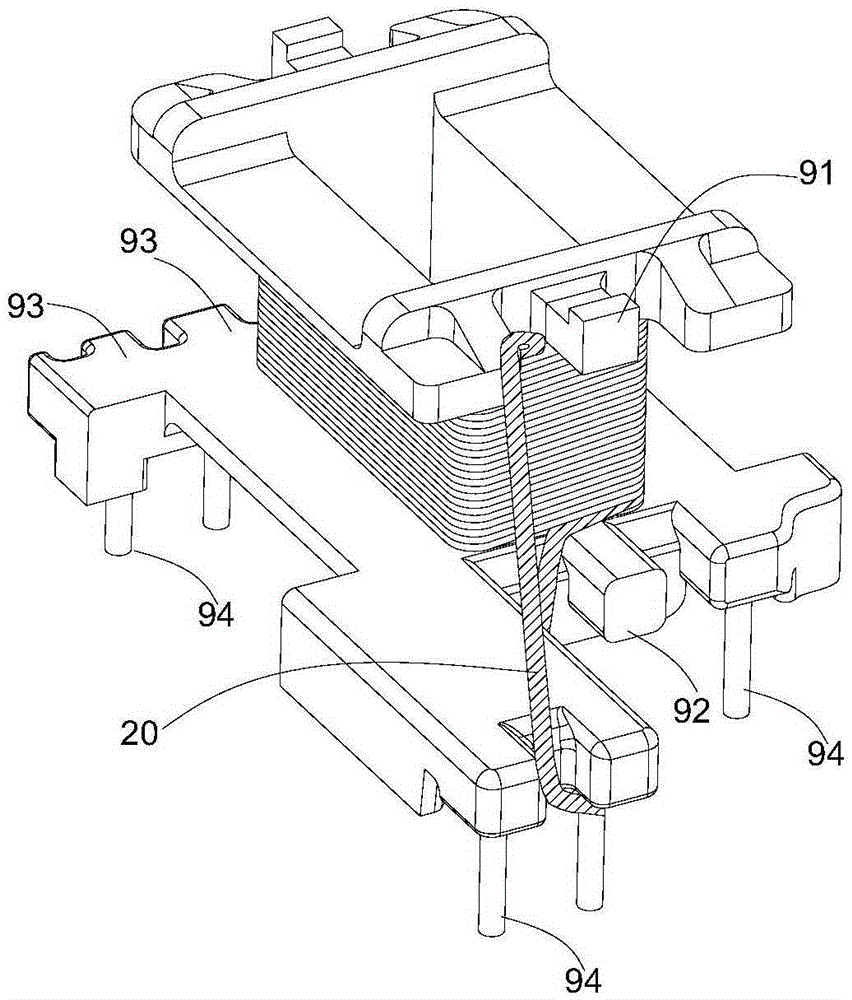

Type-C portable charger capable of reducing common-mode interference and transformer of Type-C portable charger

ActiveCN105405602AMiniaturizationAchieve high efficiencyTransformersTransformers/inductances coils/windings/connectionsWinding machineFine line

The invention discloses a Type-C portable charger capable of being automatically produced and reducing common-mode interference, a transformer and a winding method of the Type-C portable charger. The charger comprises the transformer and a winding structure of the transformer, wherein the transformer is in an EE-type structure, of which the effective sectional area of a magnetic core is greater than or equal to 40 square millimeters and which is small in size and low in cost; the winding structure of the transformer comprises a main winding, an auxiliary wining, a shielding winding and a secondary winding; the main winding is divided into a plurality of sub-windings which are connected in parallel and reduce the common-mode interference by reducing a voltage difference between an initial line and a tail line of the main winding; the sub-windings are in a structure that the sub-windings are individually and tightly wound for one layer; two fine lines, of which the sum of the sectional area is equal to the sectional area of a required single thick line and which can be automatically wound by a winding machine, are adopted by the secondary winding for winding; and outgoing lines of the secondary winding are suspended on PINs of a transformer skeleton, and are distributed at the top part and the bottom part of the transformer skeleton respectively, so as to meet the safe specified distance. Procedures and participants are reduced; the time is saved; winding packets are reduced; and the automatic degree is improved.

Owner:江西吉安奥海科技有限公司

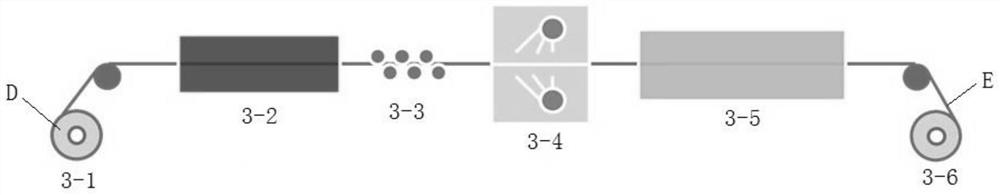

High-deep-drawability ultra-pure ferritic stainless steel and manufacturing method thereof

PendingCN114058972AImprove deep drawing performanceReduce processing defect rateSS - Stainless steelExhaust pipe

The invention relates to high-deep-drawability ultra-pure ferritic stainless steel and a manufacturing method thereof. A stainless steel strip comprises the following chemical components in percentage by mass: less than or equal to 0.025% of C, less than or equal to 1.00% of Si, less than or equal to 1.00% of Mn, less than or equal to 0.040% of P, less than or equal to 0.030% of S, 17.0-19.0% of Cr, 0.75-1.50% of Mo, less than or equal to 0.025% of N, greater than or equal to 8 (C + N) and less than or equal to 0.80% of Ti + Nb, and the balance of Fe and inevitable impurity elements. According to the invention, large-deformation-quantity cold deformation is achieved through reciprocating type multi-pass rolling machining, and the manufactured ultra-pure ferrite stainless steel strip has good deep drawing forming performance and can meet the machining requirement for deep drawing of the automobile exhaust pipe.

Owner:鞍钢联众(广州)不锈钢有限公司

Channel steel machining, corner shearing and bending machine and machining method

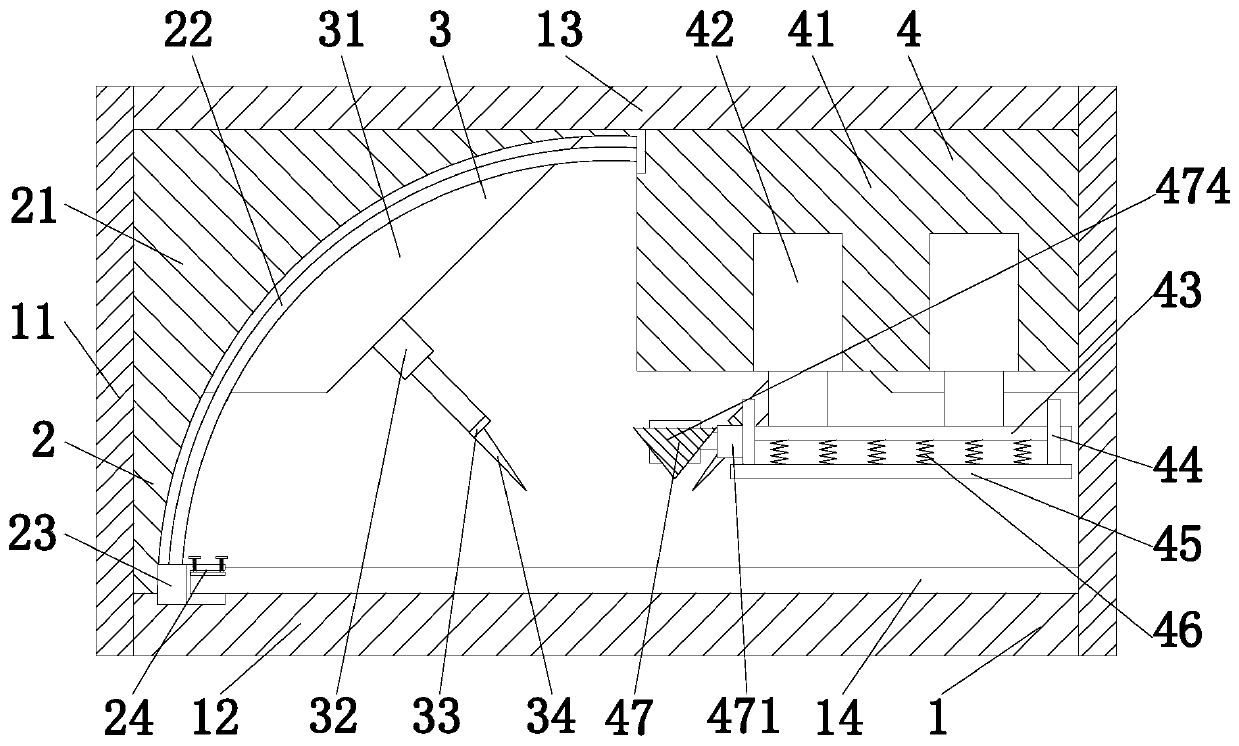

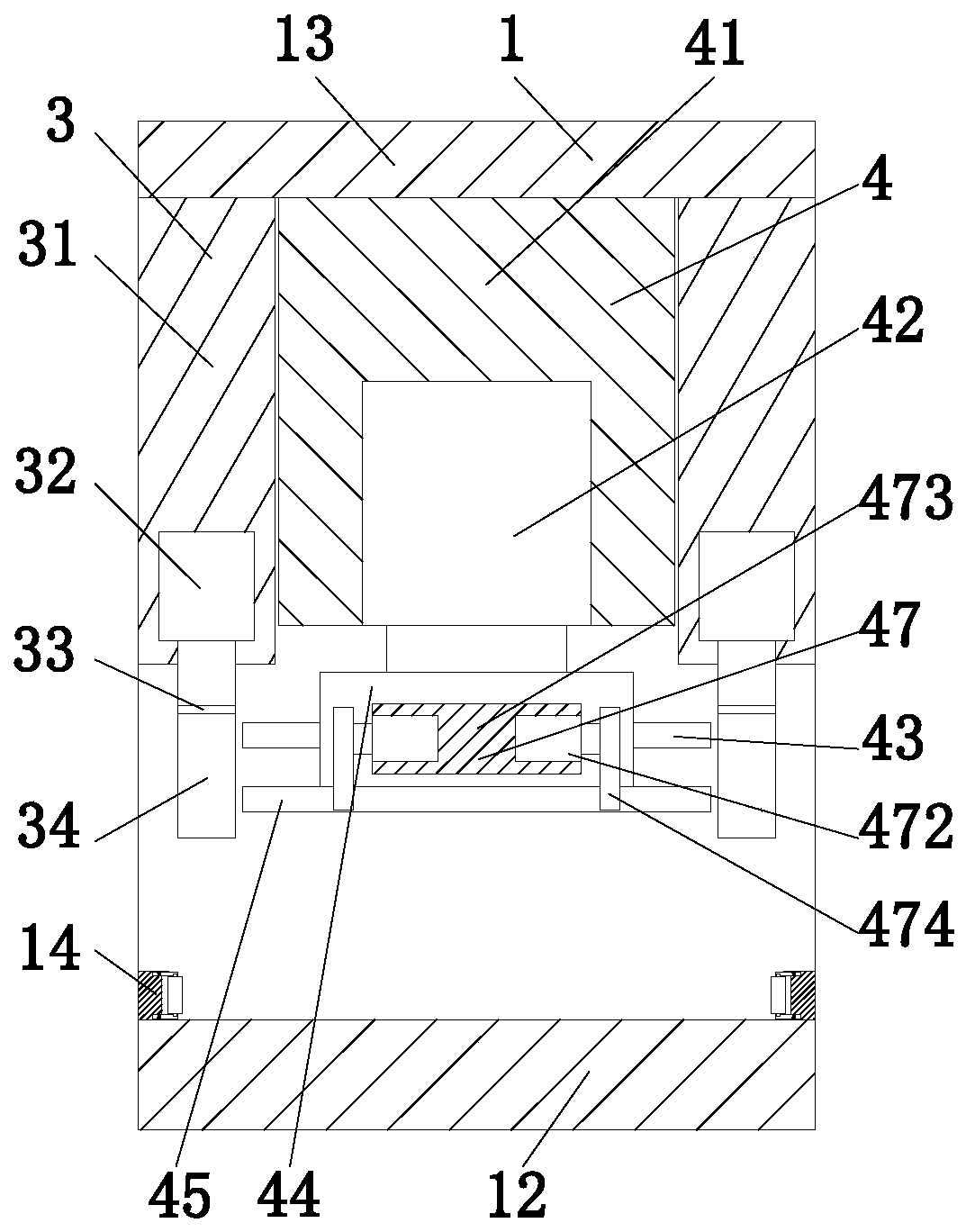

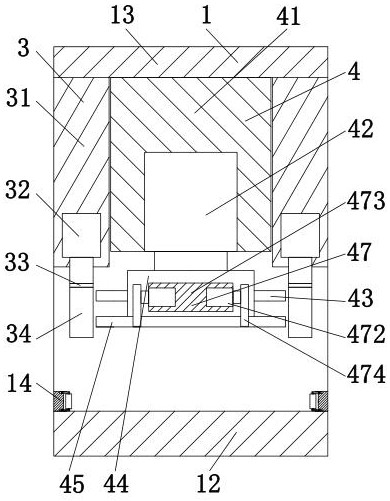

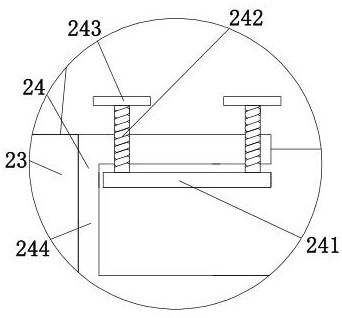

ActiveCN110587316ASolve the problems of low quality and high processing defect rateAvoid deformationShearing machinesOther manufacturing equipments/toolsEngineeringMachining process

The invention relates to a channel steel machining, corner shearing and bending machine and a machining method. The machine comprises a supporting device, a bending device, corner shearing devices anda fixing device. The cross section of the supporting device is of a homocentric-squares-shaped structure, the bending device is mounted on the inner end face of the left side of the supporting device, the fixing device is mounted on the inner end face of the right side of the supporting device, and the corner shearing devices are symmetrically installed on the front and back of the supporting device. The machine can solve the problems that an existing channel steel bending machine often adopts a roller cooperation mode to make channel steel bent by a certain angle, accordingly bent portions have radians, and bending of channel steel needing right angles cannot be completed. Besides, the problems that in the using process of the existing channel steel bending machine, corner shearing portions are lack of supporting, the channel steel is likely to deform in the machining process, the quality of the machined channel steel is low, and the defective rate of machining is high can be solved.

Owner:杭州百尊五金制造有限公司

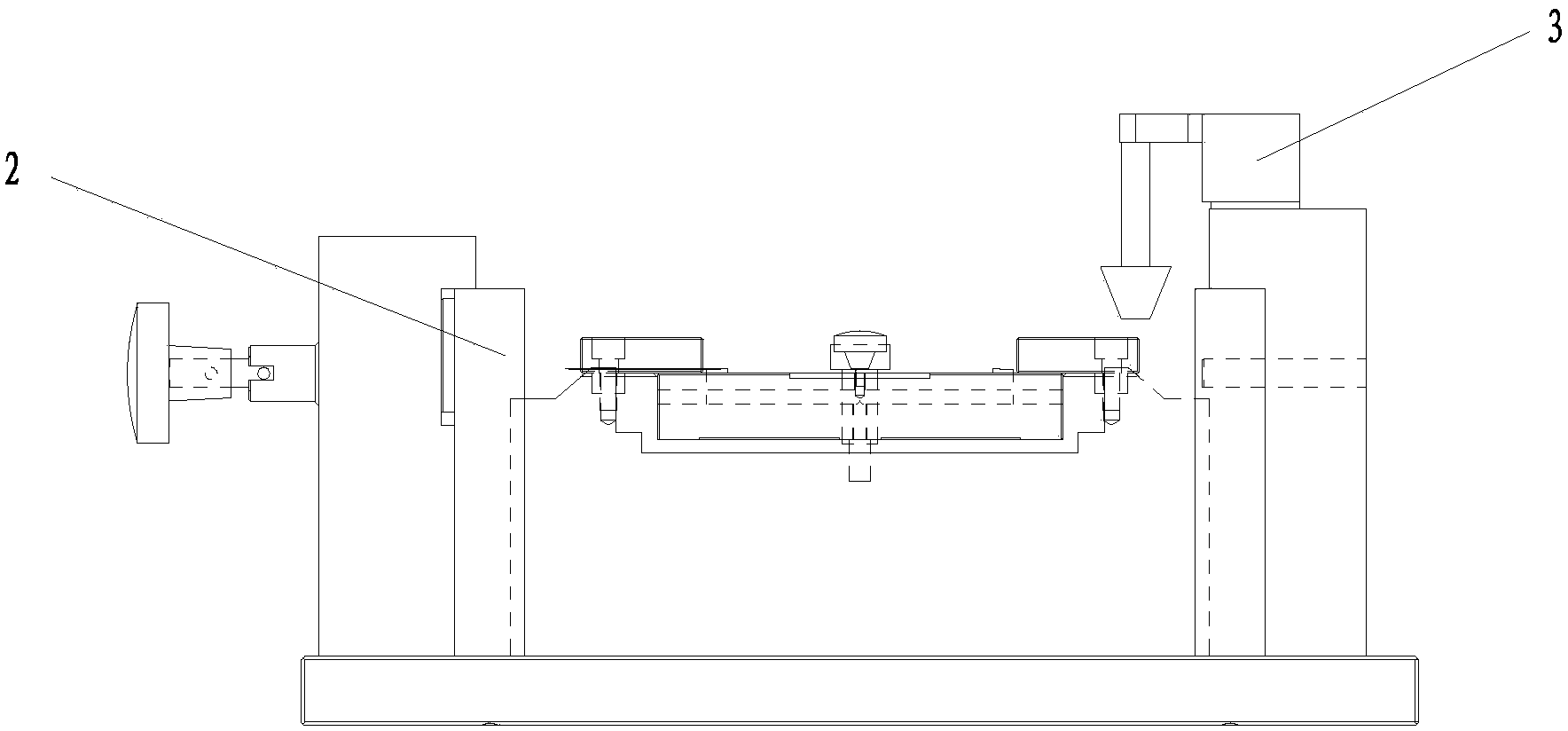

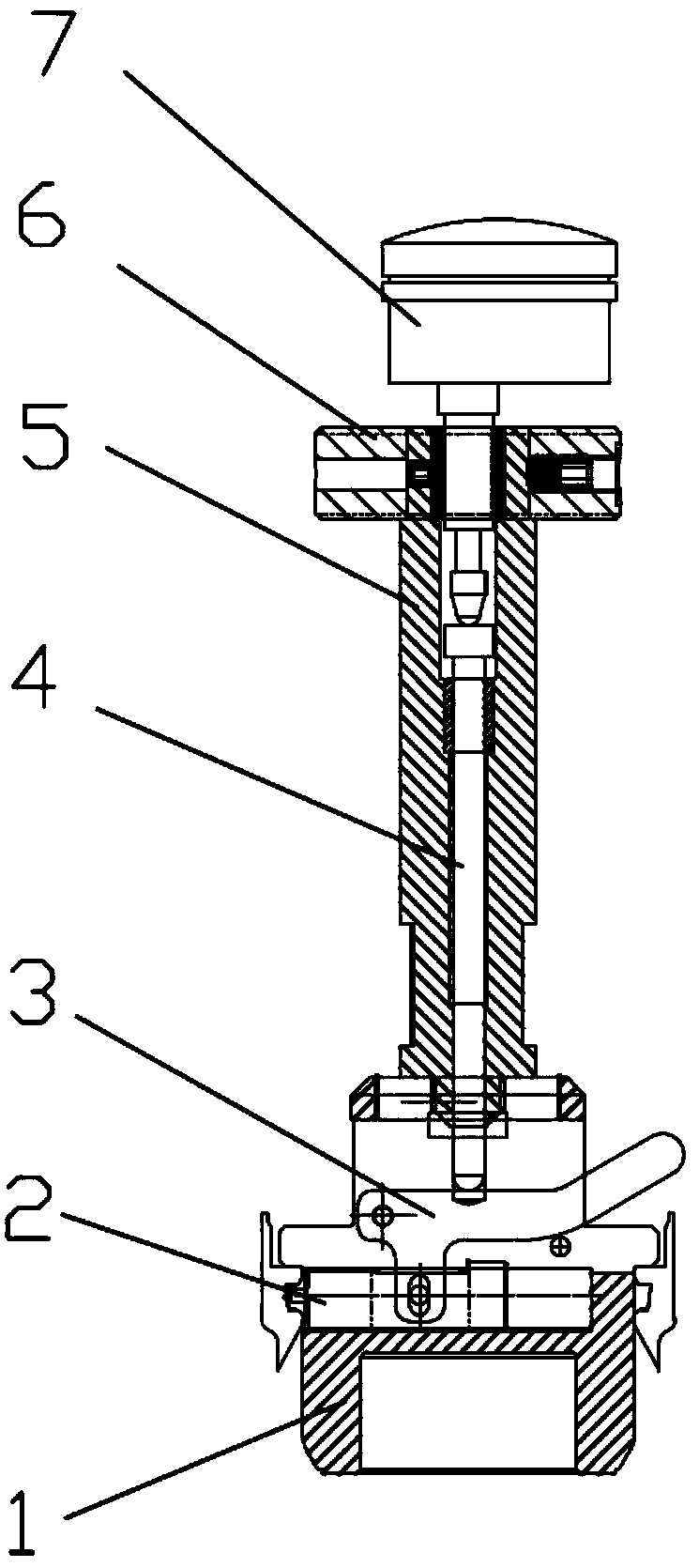

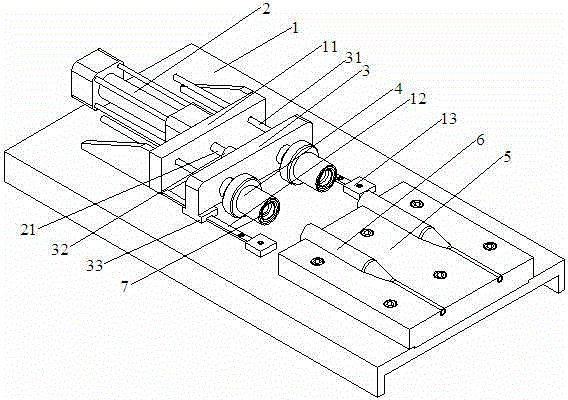

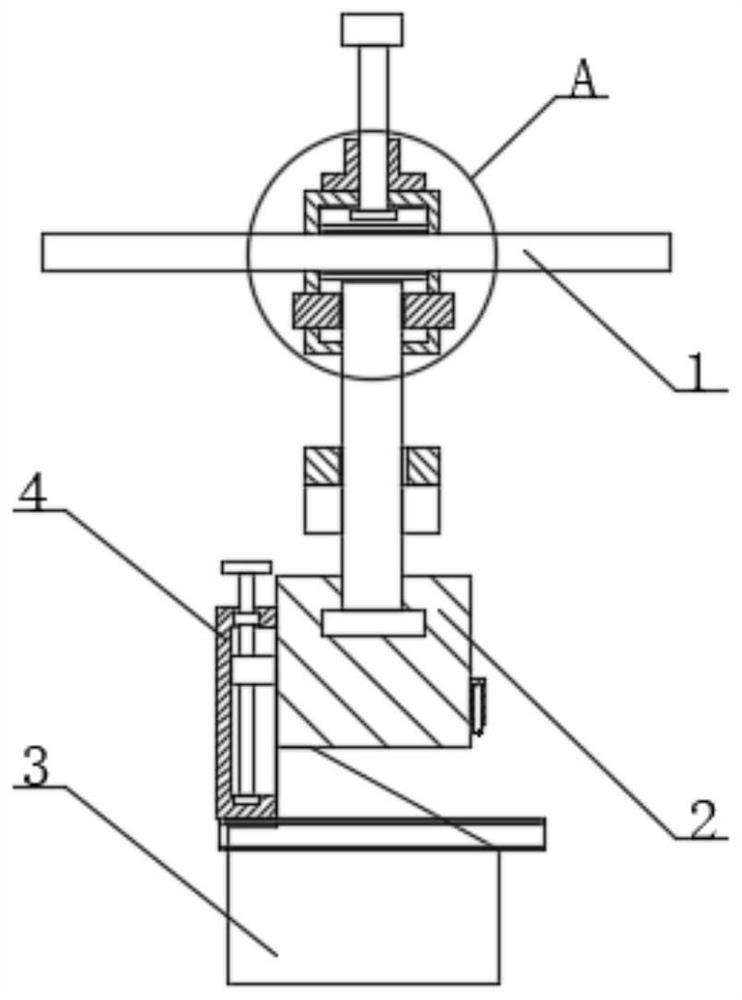

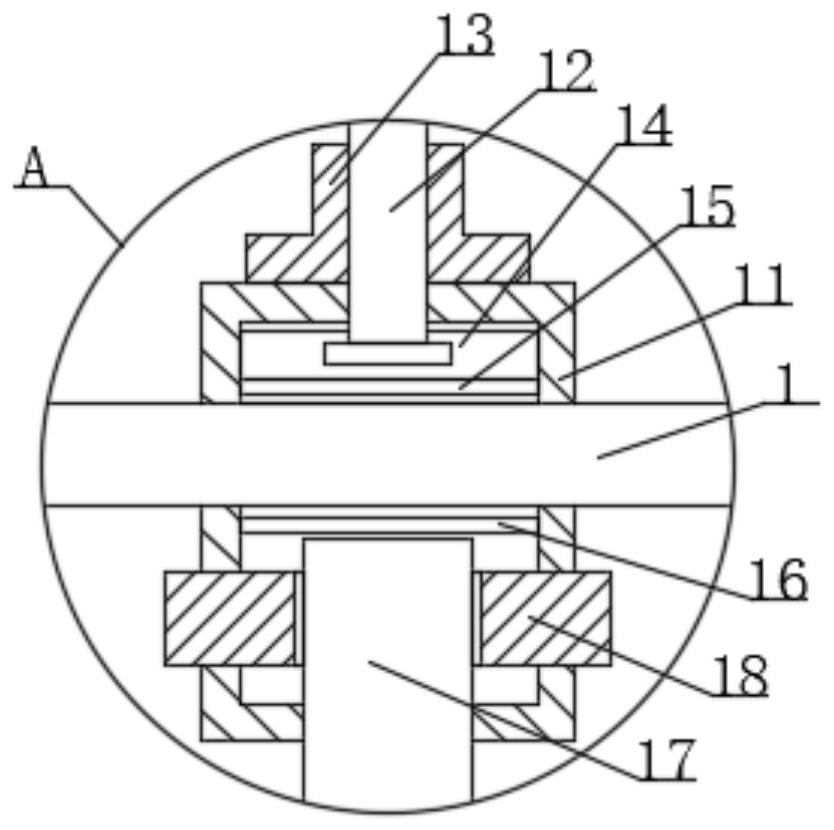

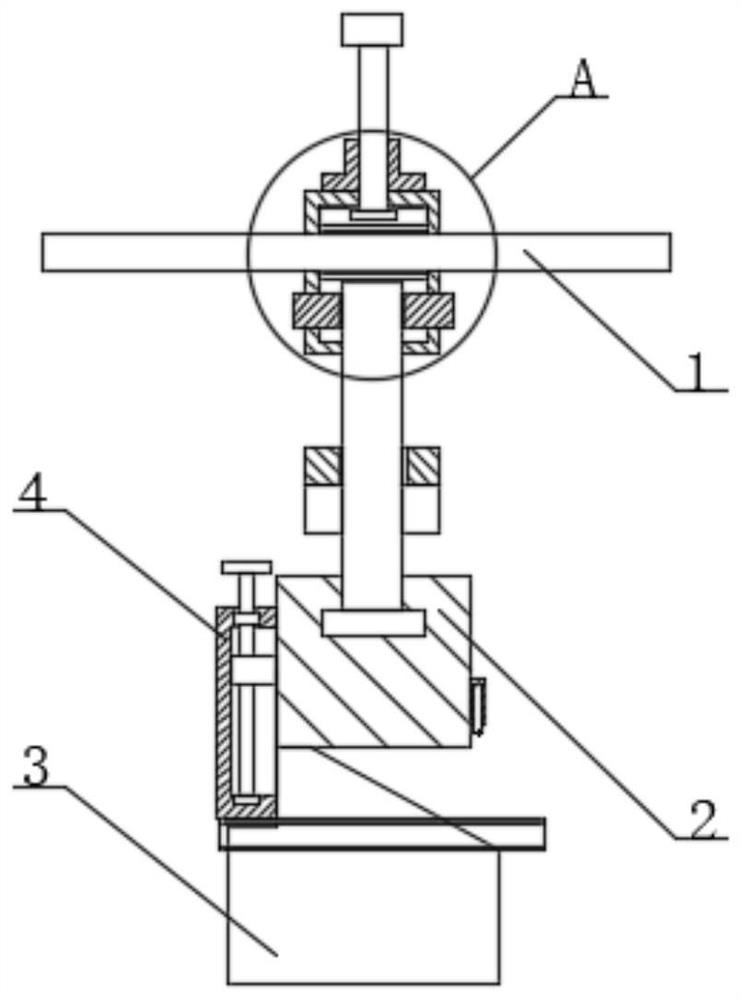

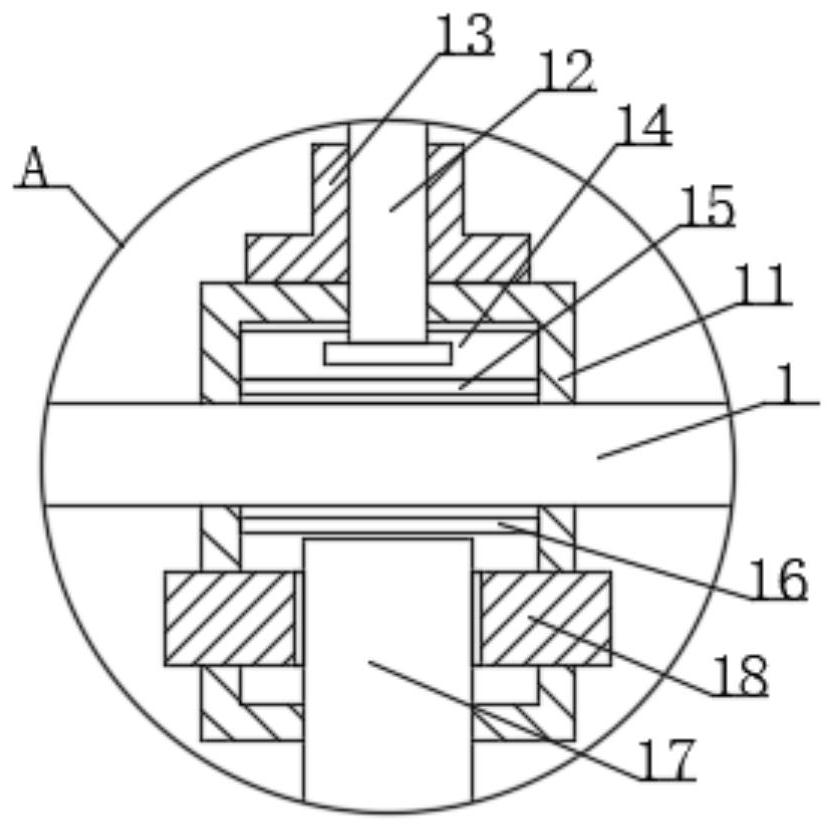

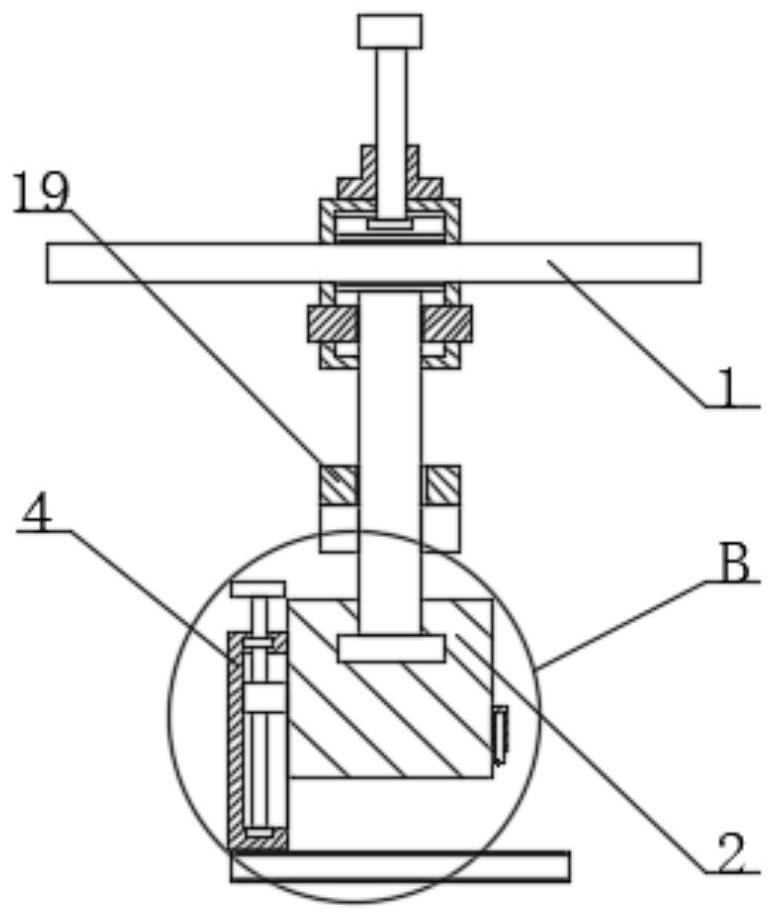

Hole coaxiality detection device of automobile brake system clamp body

InactiveCN103644831AEasy to detectAccurate dataMechanical measuring arrangementsDrive shaftBraking system

The invention relates to a hole coaxiality detection device of an automobile brake system clamp body. The hole coaxiality detection device comprises a positioning shaft (1), a detection head (2), a crank arm (3), a transmission shaft (4), a support shaft (5), an adjusting knob (6) and a dial indicator (7), wherein the positioning shaft (1) is completely matched with a detected workpiece datum hole, the detection head (1) is contacted with the inner diameter of the detected hole, the offset of the detection head (2) corresponding to the positioning shaft (1) is transmitted to the dial indicator through the crank arm (3) and the transmission shaft (4) and expressed in a numerical form directly. A maximum value read when a rotating support shaft (5) rotates for a cycle is the offset of the detected hole. The detection device provided by the invention has the characteristics of convenient detection, accurate data, easy operation and the like, has an actual using effect for detection of the hole coaxiality of the automobile brake system clamp body, enables the production and detection efficiency of the automobile brake system clamp body to be greatly improved, and greatly reduces the processing reject ratio of the automobile brake system clamp body.

Owner:大久制作(大连)有限公司

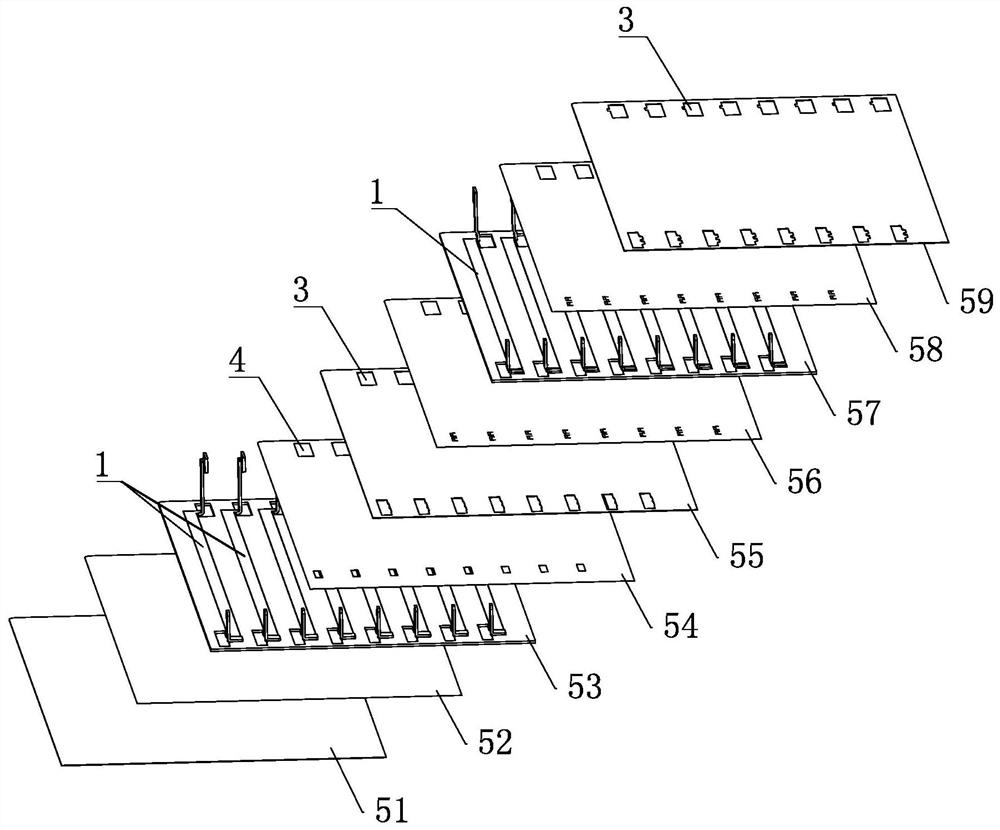

Plug press-in device for bats

InactiveCN105855844APrecise positioningReduce bad scratchesMetal working apparatusCylinder headEngineering

A plug press-in device for bats comprises a frame, a cylinder, a pressing plate, pressing heads and a fixing plate. The cylinder is mounted on a cylinder fixing plate of the frame, a cylinder head is connected with the pressing plate through the cylinder fixing plate, and the two pressing heads are connected to the pressing plate. A pair of guide rails is arranged in front of the cylinder fixing plate on the frame. Two positioning rods on the back face of the pressing plate extend out of the cylinder fixing plate. A pair of guide grooves is further formed in the lower side of the pressing plate and matched with the guide rails on the frame. The pressing plate and the pressing heads can move on the guide rails through the guide grooves. In the moving process, the two positioning rods on the pressing plate also move along with the pressing plate and can position the pressing plate movably through the cylinder fixing plate, and the situation that small deviation of the pressing plate is caused by shock generated when plugs are pressed into the bats can be prevented. The plug press-in device has the beneficial effects that the plugs and bat bodies can be precisely positioned, the defects of scratches of the bat bodies are reduced, the machining reject ratio is low, and production efficiency of assembling of the bat bodies and the plugs of the bats is greatly improved.

Owner:林裕雄

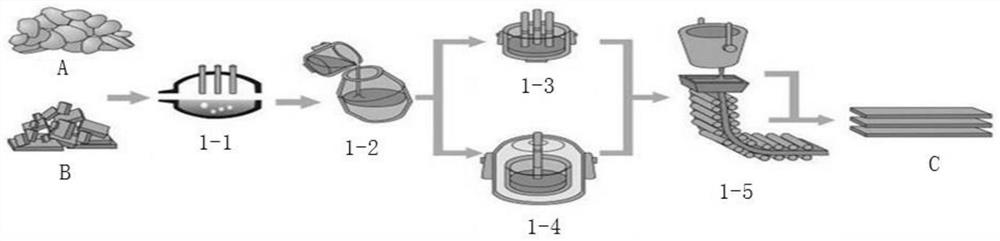

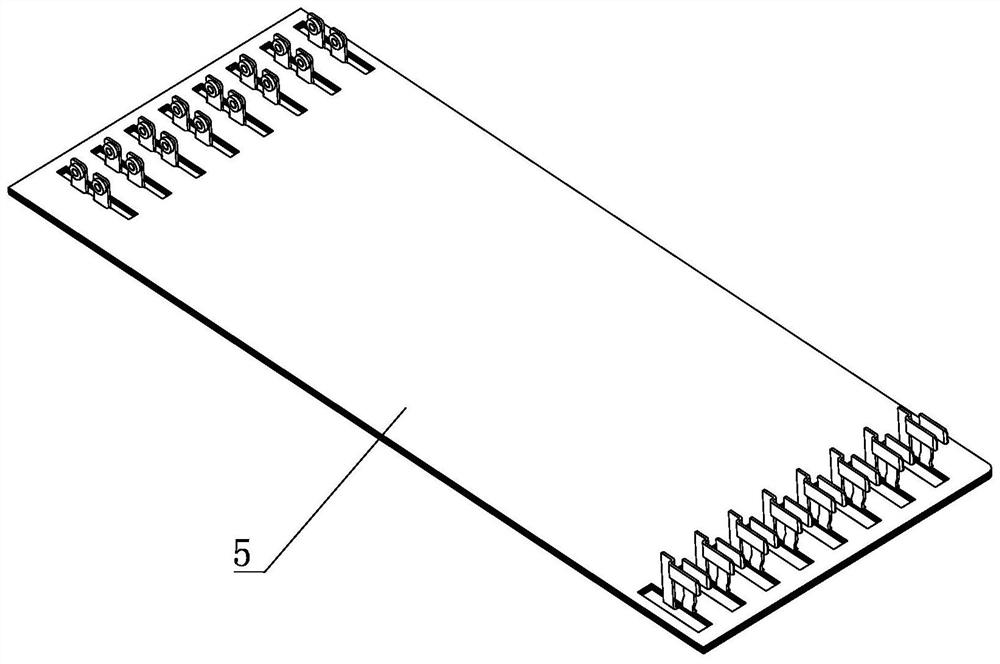

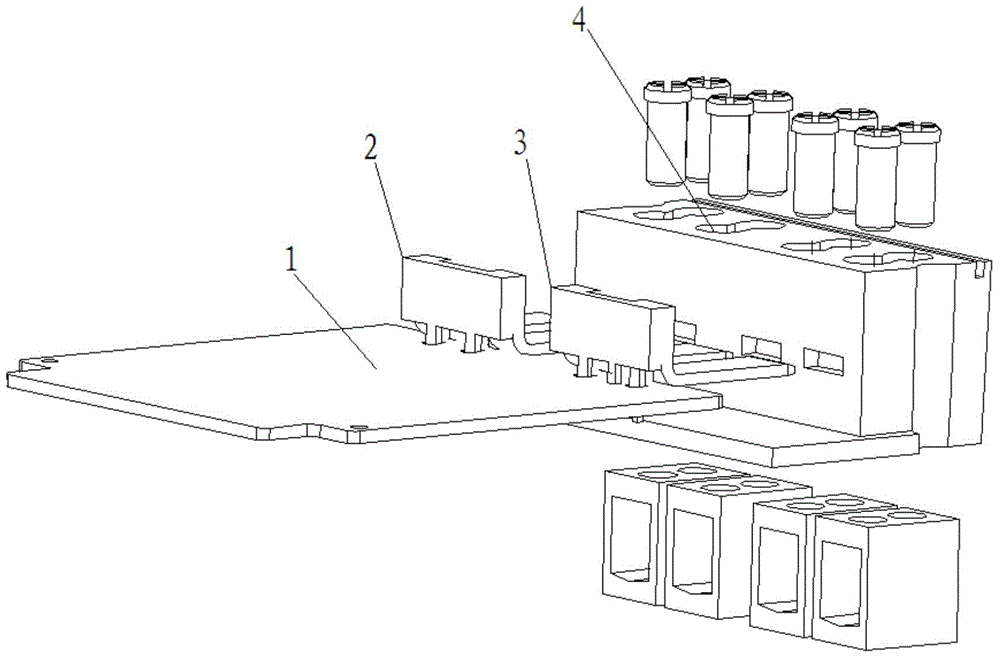

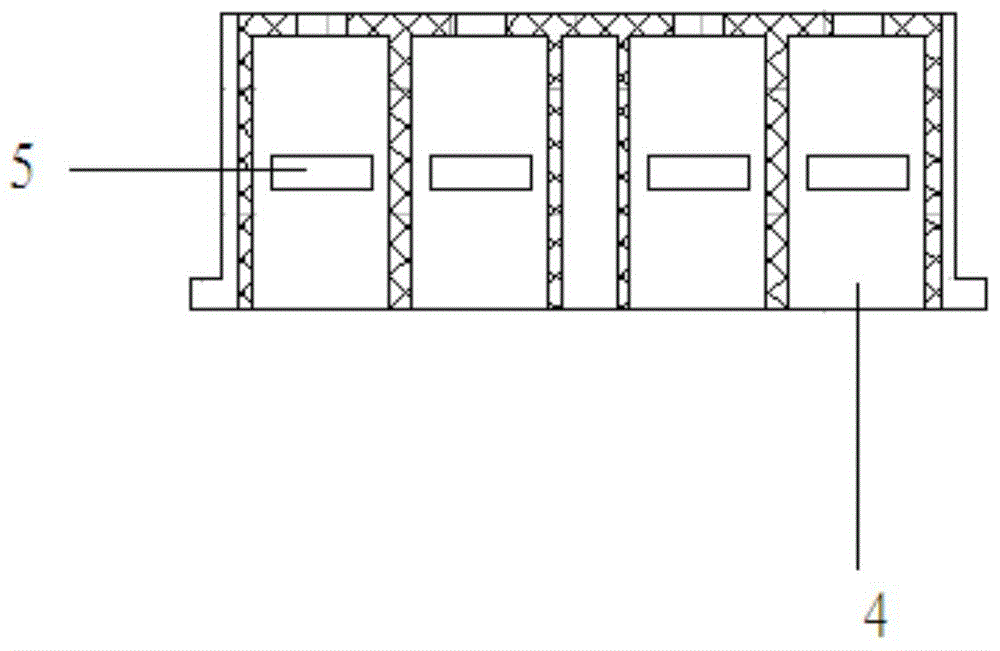

Production and manufacturing method of copper bar body

ActiveCN113113825AImprove insulation performanceQuick Plug AdapterContact member manufacturingContact member assembly/disassemblyMechanical engineeringIndustrial engineering

A production and manufacturing method of a copper bar body comprises the following steps: manufacturing a copper bar through stamping, bending the two ends of the copper bar to form a front-end contact piece and a rear-end contact piece, and deburring the copper bar; according to the shape and size of the copper bars, processing a plurality of through hole grooves which are through up and down in an insulating plate, embedding the copper bars in the corresponding through hole grooves, and processing windows for exposing the front-end contact piece and the rear-end contact piece at the two ends of the insulating plate; cutting the prepreg, and forming through holes for avoiding the front-end contact piece and the rear-end contact piece in the prepreg; then carrying out typesetting in a stacking form; putting the multi-layer stacked body, obtained after typesetting is completed, into a pressing machine to be subjected to hot pressing; and finally, processing the multi-layer stacked body after hot pressing into a plurality of copper bar bodies. The manufacturing process is simple, the production efficiency is high, and the produced copper bar body product is good in structural strength and insulating property, has the characteristic of quick plugging and switching of electric energy or signals, and is convenient to disassemble and maintain when being applied to the field of connectors.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

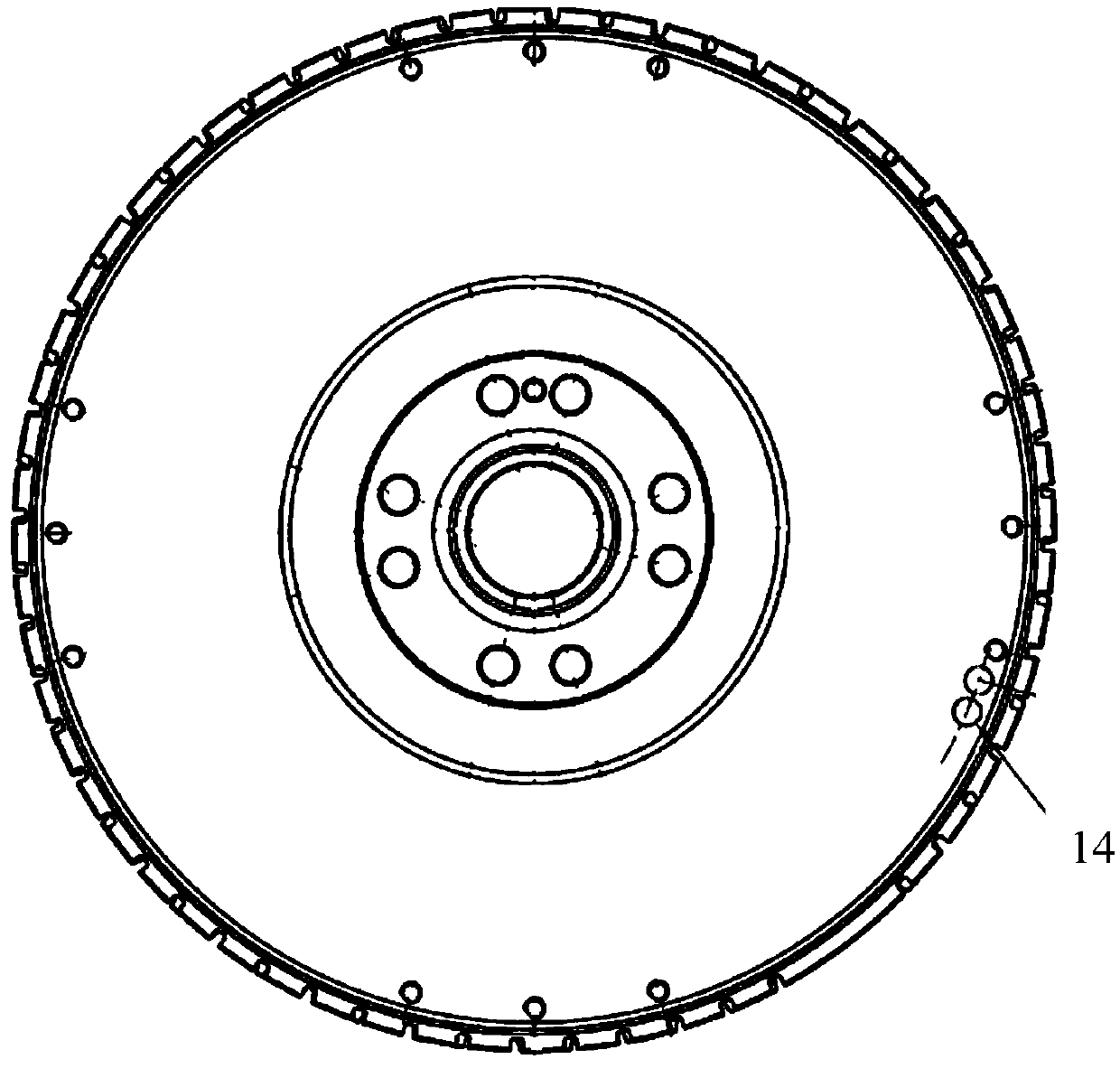

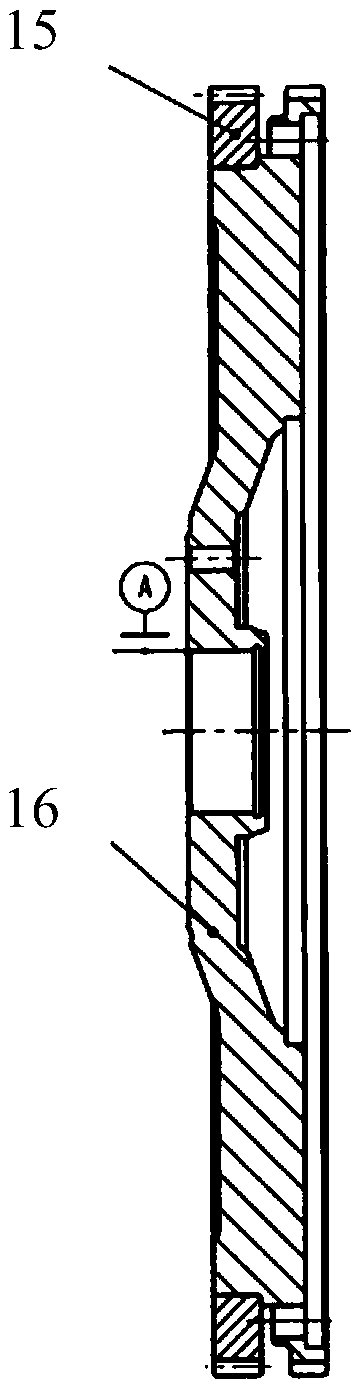

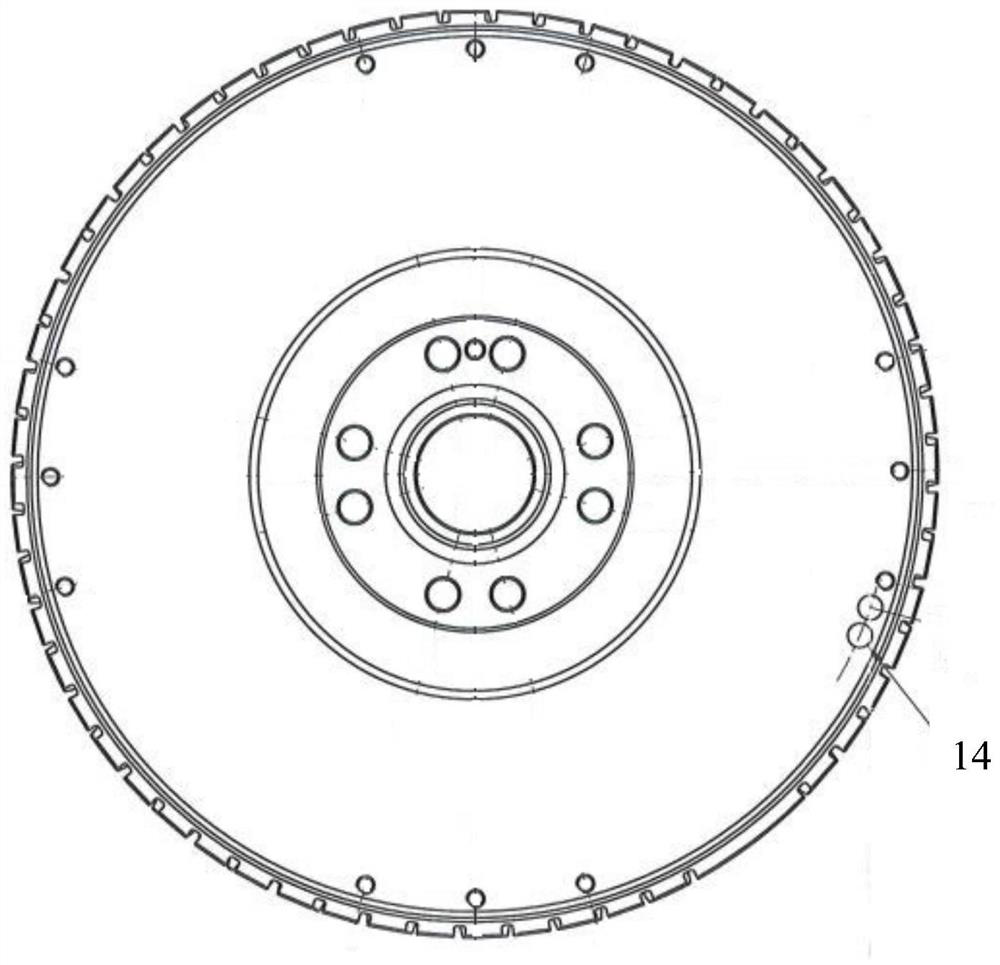

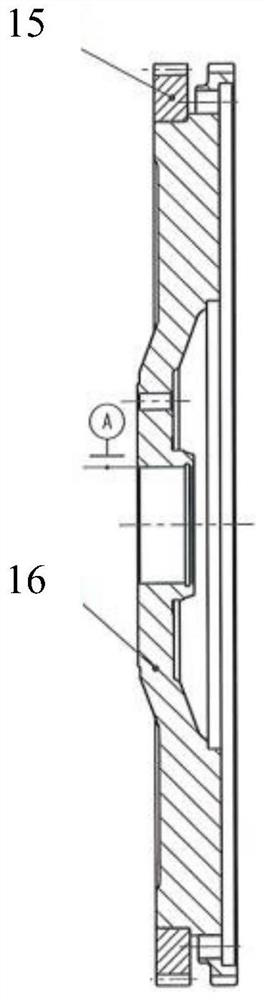

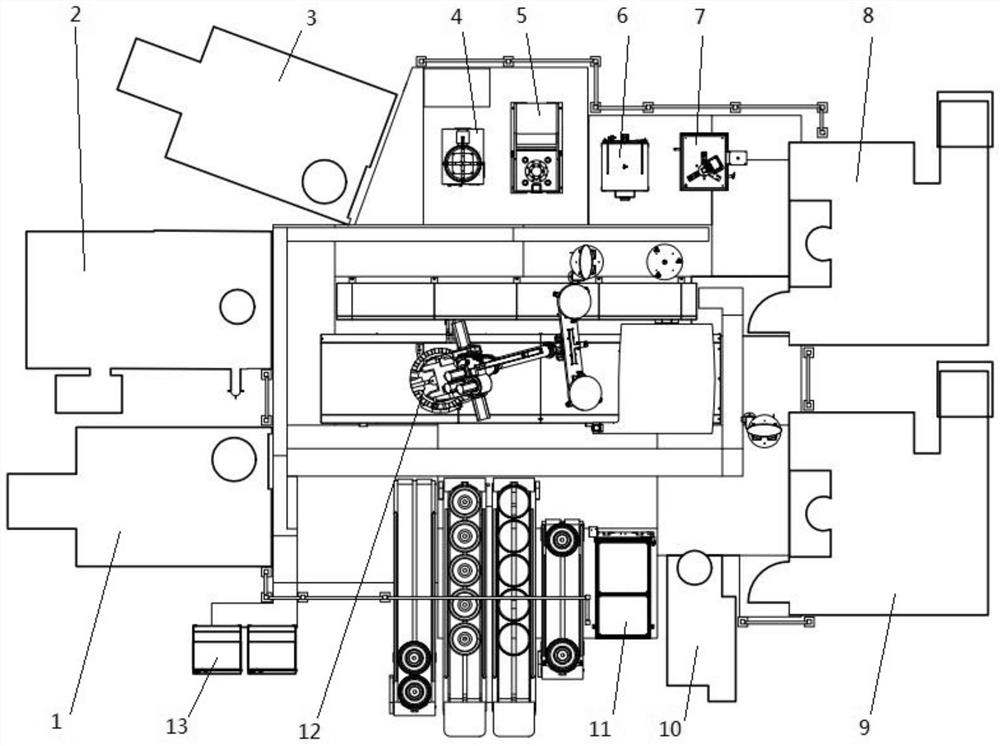

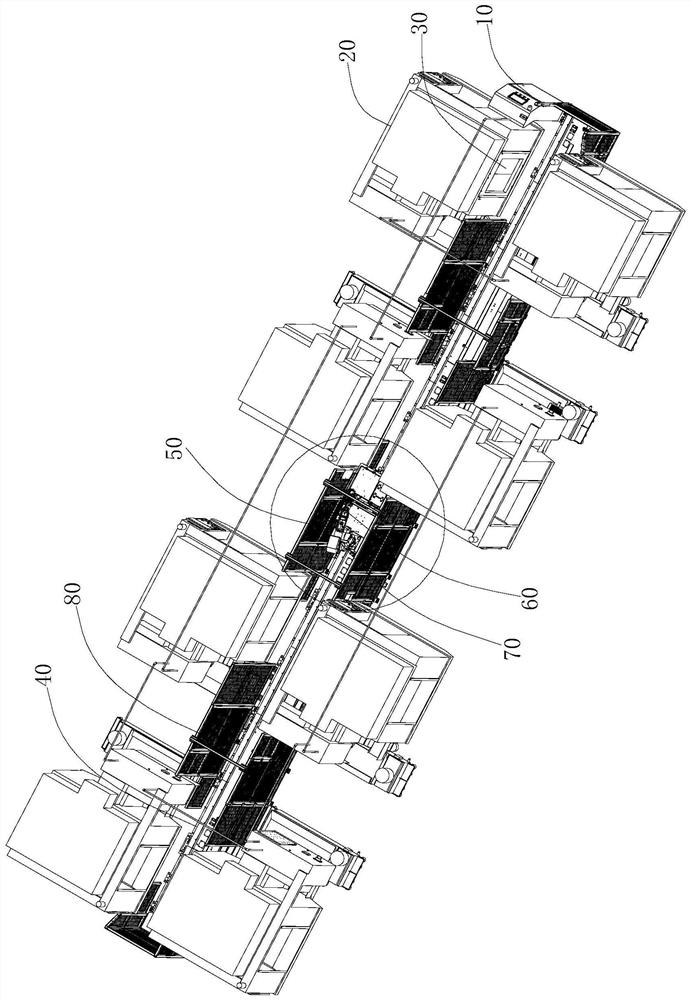

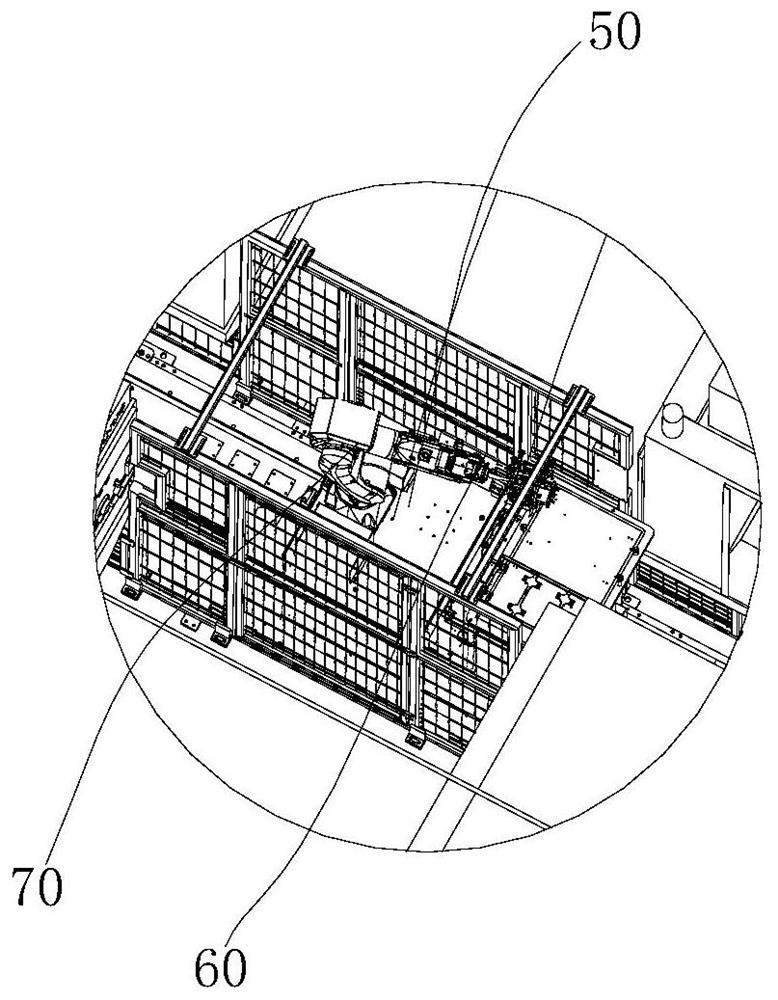

Device and method for machining flywheel assembly

ActiveCN109093397AReduce lossesReduce manual labor intensityOther manufacturing equipments/toolsDynamic balanceEngineering

The invention discloses a device and a method for machining a flywheel assembly. The whole machining processes are sequentially as follows: a first vertical lathe is used for machining the front surface of a flywheel; a horizontal machining unit is used for performing flywheel signal gear machining; a gear ring heating device is used for heating a gear ring; a press machine is used for carrying out gear ring and flywheel pressing and sleeving; a second vertical lathe is used for machining the working face of the flywheel; a cleaning workbench is used for cleaning the flywheel; an online detection device is used for carrying out online detection on the flywheel; an infrared scanning unit is used for carrying out infrared scanning and positioning on the flywheel; a first vertical machining unit is used for carrying out flywheel hole position machining; a second vertical machining unit is used for carrying out flywheel installation hole machining; a laser marking machine is used for carrying out laser printing of an ignition mark; and dynamic balance equipment is used for carrying out dynamic balancing of the flywheel. According to the device and the method, due to the adoption of a roundabout layout of automatic operation of manipulators, the labor intensity of workers and the number of the workers are greatly reduced, the fact the process capabilities of important sizes of products are all 1.67 or above is ensured, the reject ratio of product machining is remarkably reduced, and the monthly waste loss is reduced by 50% or above.

Owner:十堰东风飞斯特机械制造有限公司

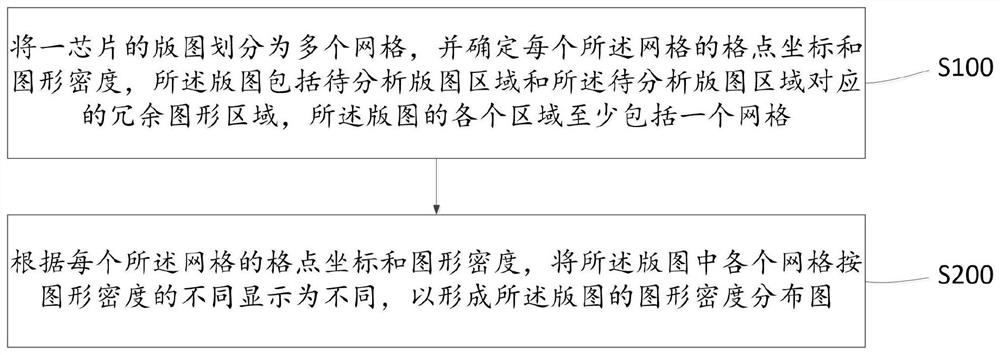

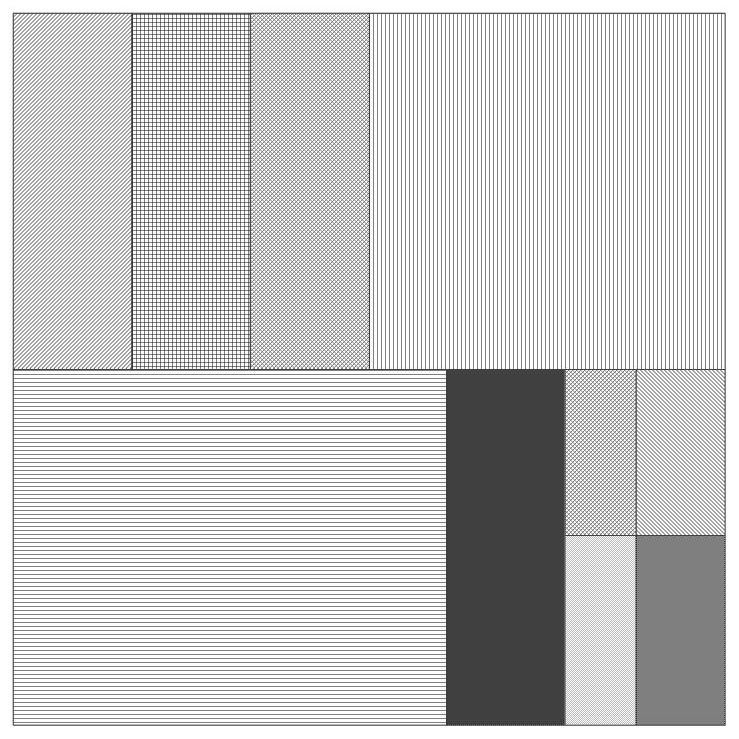

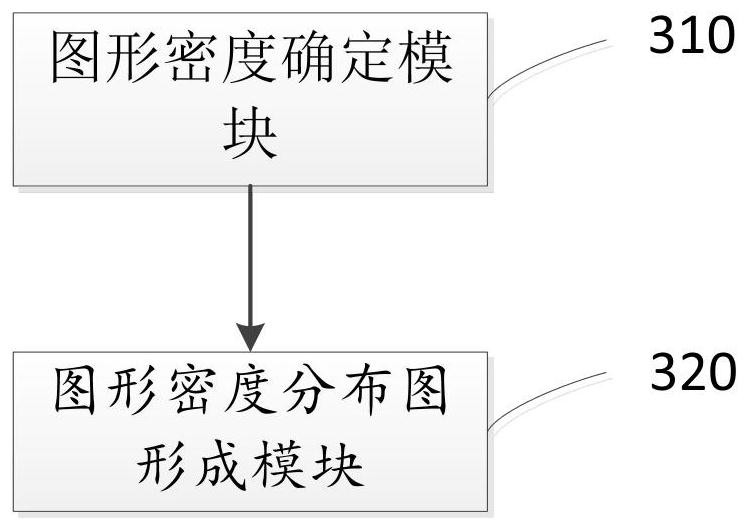

Method and device for analyzing graph density of chip and electronic equipment

PendingCN112818632AImprove analysis efficiencyImprove yieldComputer aided designSpecial data processing applicationsAlgorithmSemiconductor technology

The invention provides an analysis method and device for the graph density of a chip and electronic equipment, and is applied to the technical field of semiconductors. According to the graph density analysis method provided by the invention, after the graph density of each region in the edition graph is calculated, the graph density of each region is displayed in a graph display mode through the preset display strategy; therefore, a technician can visually check the distribution condition of the graph density of each area in the layout, the analysis efficiency of the graph density of the layout is improved, finally, the process defect rate in the subsequent manufacturing process is reduced, and the product yield is increased.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

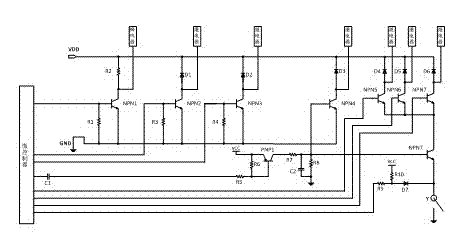

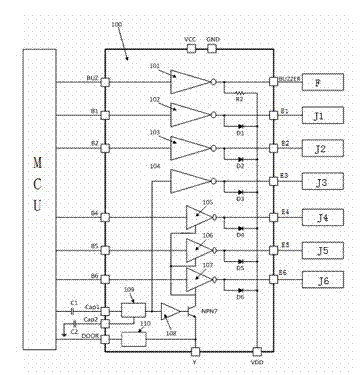

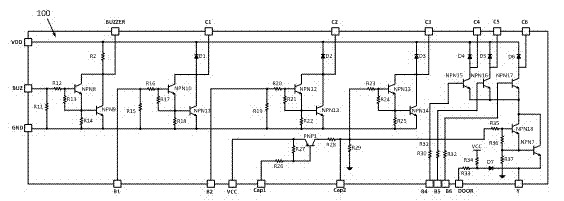

Drive control integrated circuit special for microwave oven

InactiveCN104730969AReduce the number of piecesSmall sizeProgramme controlDomestic stoves or rangesControl setMicrowave oven

The invention discloses a drive control integrated circuit special for a microwave oven, and relates to circuit structures, in particular to the improvement technology of a drive circuit structure. The drive control integrated circuit special for the microwave oven is composed of a microcontroller, an integrated chip, a buzzer and six relays. A buzzer drive circuit and six relay drive circuits in the integrated chip are connected with the buzzer and the six relays respectively. A single-chip microcomputer detection circuit and a gate signal detection circuit are further arranged in the integrated chip. The output end of the single-chip microcomputer detection circuit is connected with a triode drive circuit and one relay drive circuit, the triode drive circuit is connected with the base electrode of a triode, the emitting electrode of the triode is grounded through a gate switch (remark: a Y end is grounded through the gate switch, when the switch is switched off, the Y end is suspended in midair, and when the switch is switched on, the Y end is grounded), and the collector electrode of the triode is connected with the three relay drive circuits. The input end of the gate signal detection circuit is connected with the gate switch, and the output end of the gate signal detection circuit is connected with a single-chip microcomputer. The drive control integrated circuit special for the microwave oven solves the problems that in the prior art, the number of peripheral elements is many, the size of a PCB is large, and the design cost of a system and machining reject ratio are high.

Owner:SINOTECH MIXIC ELECTRONICS

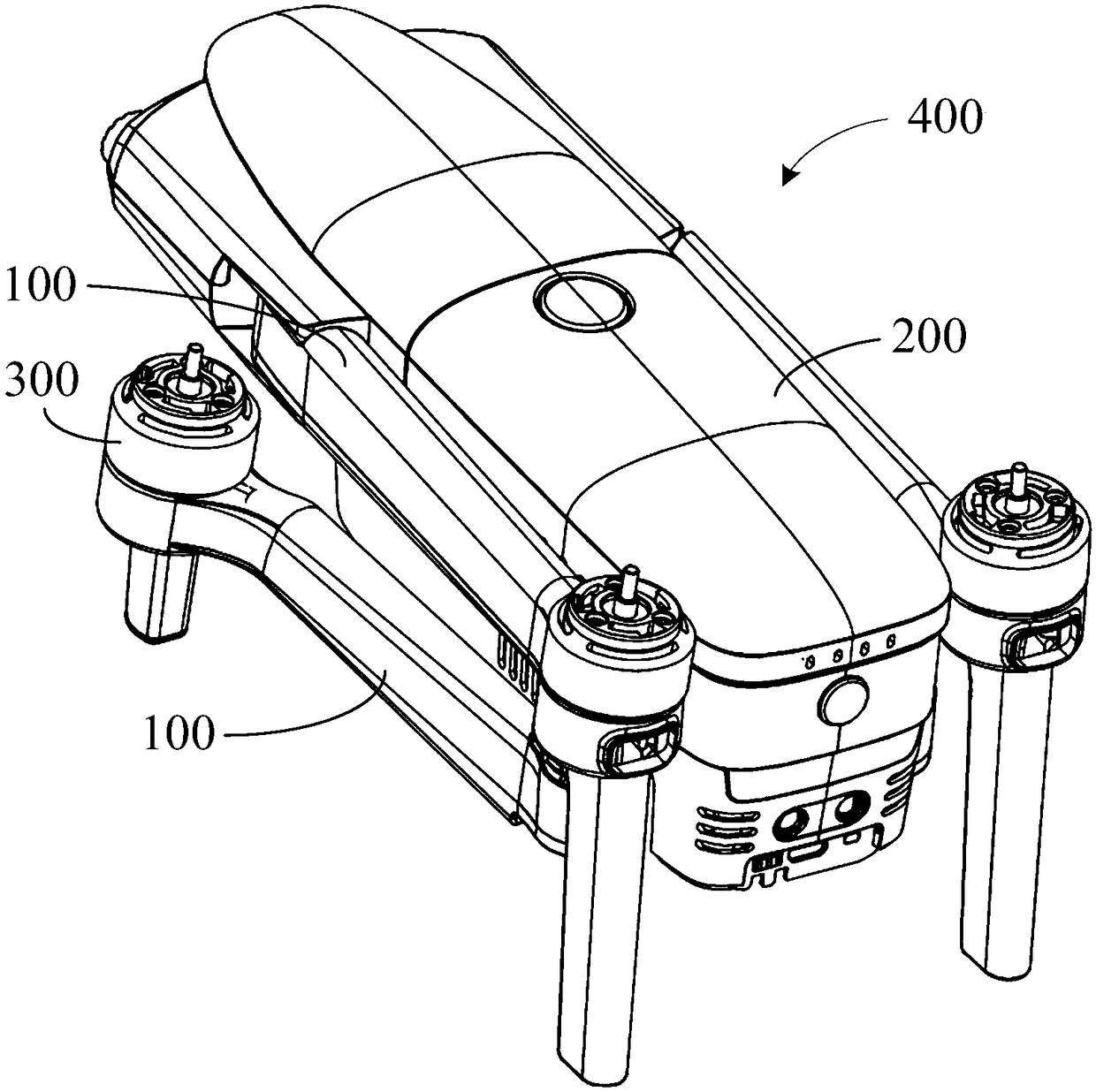

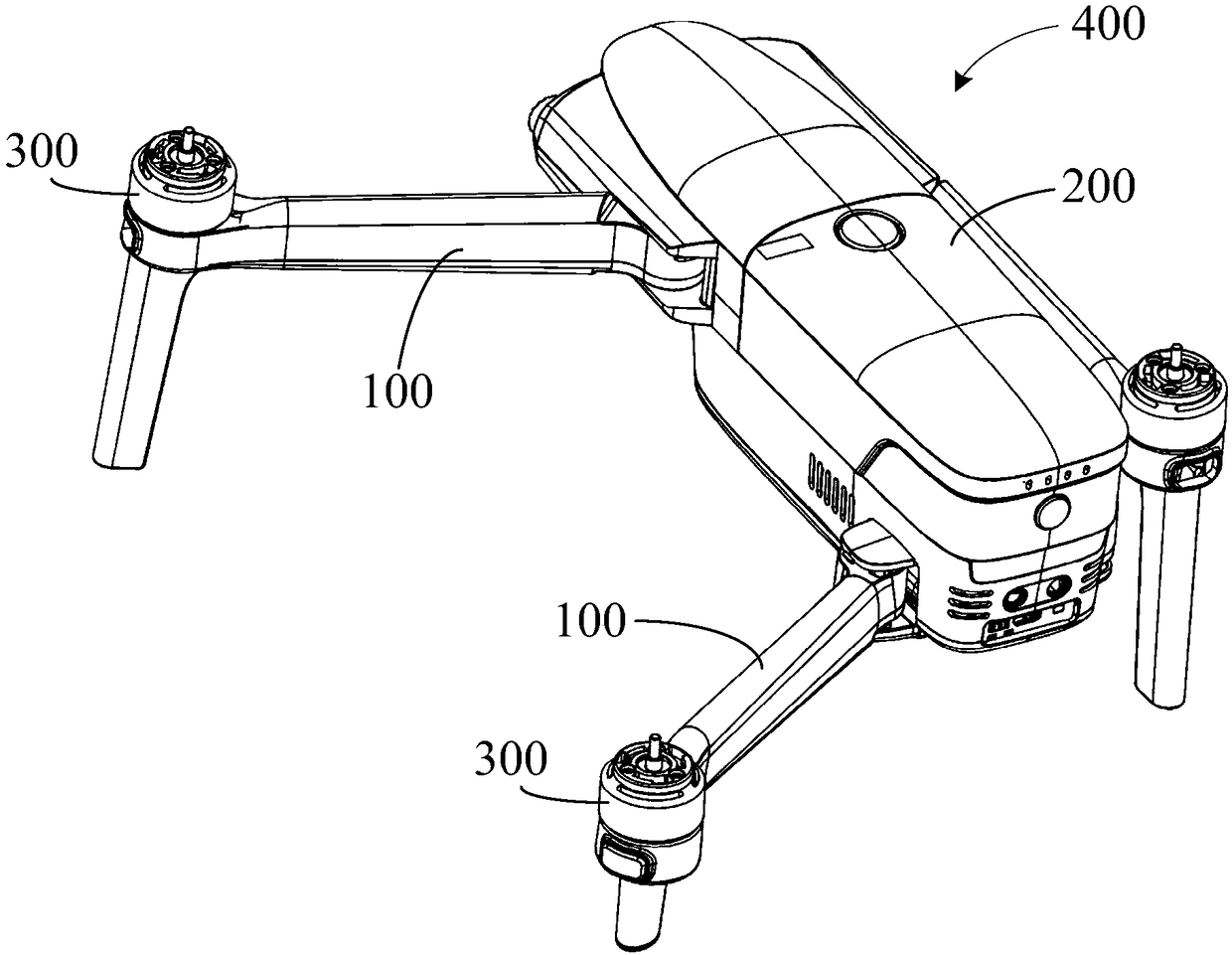

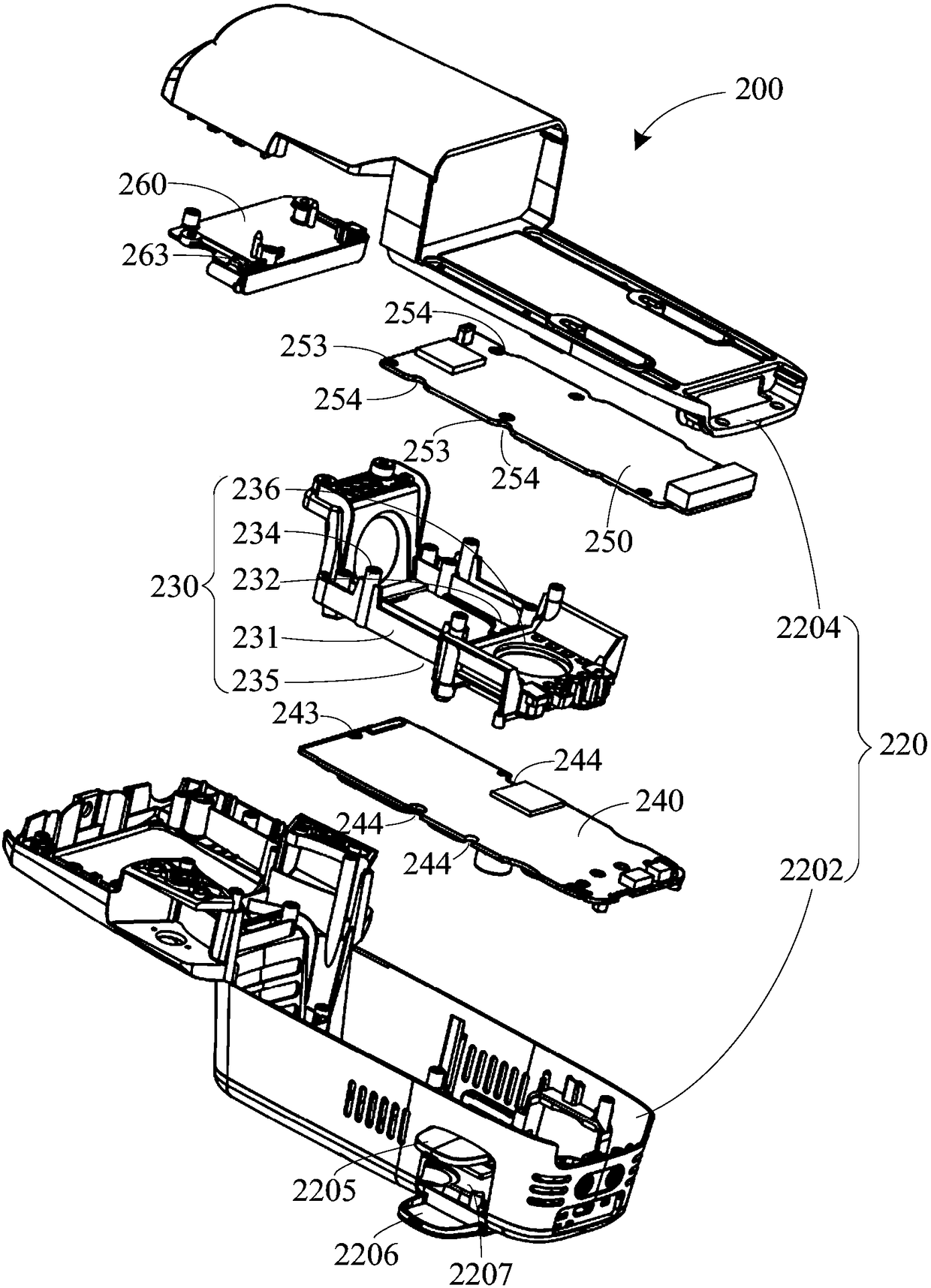

Unmanned aerial vehicle and fuselage assembly thereof

PendingCN108609156AReduce manufacturing costSimple internal and external structureFuselage framesEngineeringUnmanned spacecraft

The invention provides an unmanned aerial vehicle and a fuselage assembly thereof. The fuselage assembly comprises a shell, a bracket and an internal assembly piece. The shell is provided with an accommodating cavity. The bracket is accommodated in the accommodating cavity and connected with the shell. The internal assembly piece is mounted on the bracket. In the fuselage assembly, the shell doesnot need a fixing structure used for mounting the internal assembly piece, so that the internal and external structures of the shell are concise, low in weight, easy to machine and low in machining defect rate; and the high-quality appearance can also be obtained under the low-cost condition, so that the overall manufacturing cost of the fuselage assembly is reduced.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

Y-axis positioning structure of rear fixed gauge of bending machine

ActiveCN112170562AImprove the qualified rate of hemmingEffective position positioning fastening effectMetal-working feeding devicesPositioning devicesCircular discStructural engineering

The invention discloses a Y-axis positioning structure of rear fixed gauge of a bending machine. The Y-axis positioning structure comprises a fixed beam and a Y-axis positioning block, and the periphery of the fixed beam is sleeved with a fixed seat in a sliding mode. According to the Y-axis positioning structure, a rotary table drives a connecting rod to lift in the fixed seat, so that a user caneffectively and conveniently adjust the flexibility of clamping a product body, and meanwhile, the position of the rear fixed gauge on the periphery of the connecting rod is rotated and is positionedby virtue of a clamping block, so that the position positioning and fastening effect of the rear fixed gauge can be effectively realized; a threaded rod is driven by a disc to enable the Y-axis positioning block to perform positioning adjustment on the Y-axis position through a sliding block in a sliding groove, so that the auxiliary positioning effect of the product body during bending machiningcan be more stable, and the product machining reject ratio is greatly reduced; and meanwhile, the situation that due to the fact that the positioning size of the positioning edge of the product bodyis too small or the special-shaped edge cannot be effectively and vertically positioned is further avoided, and the edge folding yield of sheet products is effectively increased.

Owner:深圳市龙诚行实业有限公司

Flexible display substrate, method for manufacturing the same, and display device

ActiveCN109887416BReduce processing defect rateImprove adhesionFinal product manufacturePhotovoltaic energy generationDisplay deviceFlexible display

The present application relates to a flexible display substrate, a manufacturing method thereof, and a display device, and belongs to the field of display technology. The flexible display substrate includes: a flexible base substrate and a wiring layer stacked on the flexible base substrate, a first adhesion enhancement layer and a first insulating layer, the first insulating layer is located on one side of the wiring layer, and the first The adhesion enhancement layer is located between the first insulation layer and the wiring layer, and the first adhesion enhancement layer is bonded to the first insulation layer and the wiring layer respectively; the flexible substrate has a bending area, and the first adhesion The orthographic projection of the adhesion enhancement layer on the flexible substrate is at least located in the bending area, the orthographic projection of the signal traces in the wiring layer on the flexible substrate is located in the bending area, and the first adhesion is enhanced layer is used to enhance the adhesion between the wiring layer and the first insulating layer. The present application is used to prevent the breakage of the signal wiring of the wiring layer of the flexible display substrate.

Owner:BOE TECH GRP CO LTD

Flywheel assembly processing device and method

ActiveCN109093397BReduce lossesReduce manual labor intensityOther manufacturing equipments/toolsWaste productFlywheel

The invention discloses a processing device and method of a flywheel assembly. The whole processing procedure is as follows: the first vertical lathe processes the front of the flywheel, the horizontal lathe processes the flywheel signal teeth, the ring gear heating device heats the ring gear, and the press machine Ring gear and flywheel pressure sleeve, the second vertical lathe is used for processing the flywheel working surface, the cleaning table is used for cleaning the flywheel, the online detection device is used for online detection of the flywheel, infrared scanning is used for infrared scanning positioning of the flywheel, and the first vertical lathe is used for processing the hole position of the flywheel , The second vertical plus is used for flywheel installation hole processing, laser marking machine for laser printing ignition marks, and dynamic balance equipment for flywheel dynamic balance and weight removal. Because the present invention adopts the circular island layout of the automatic operation of the manipulator, the manual labor intensity and the number of operators are greatly reduced, and the process capacity of the important dimensions of the product is ensured to be above 1.67, and the defective rate of the product is significantly reduced. Over 50% reduction in monthly scrap loss.

Owner:东实汽车动力零部件(湖北)有限公司

A channel steel processing shear angle bending machine and processing method

ActiveCN110587316BAvoid deformationMeet needsShearing machinesOther manufacturing equipments/toolsClassical mechanicsEngineering

The invention relates to a channel steel processing angle shearing bending machine and a processing method, comprising a supporting device, a bending device, a shearing angle device and a fixing device. A bending device is installed, a fixing device is installed on the inner end surface on the right side of the supporting device, and an angle shearing device is installed symmetrically before and after the supporting device. The present invention can solve the problem that the existing channel steel bending machine usually adopts the method of rotating rollers to bend the channel steel at a certain angle. This method makes the bending place have radians, and the bending of the channel steel that requires a right angle angle cannot be completed. , and can solve the problem that the existing channel steel bending machine lacks support for the shear angle during use, which easily leads to deformation in the process of channel steel processing, resulting in lower quality of processed channel steel and high processing defect rate. .

Owner:杭州百尊五金制造有限公司

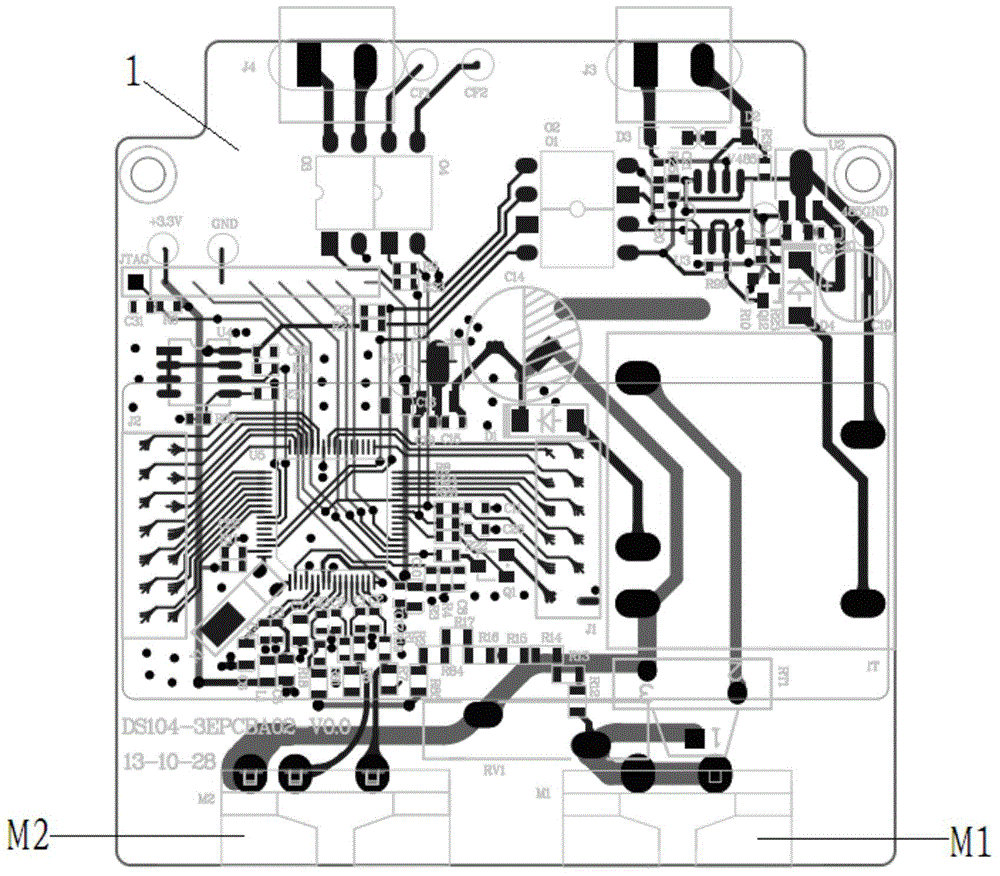

An integrated circuit board for a single-phase guide rail meter

ActiveCN103630709BSimple production processHigh degree of automationPrinted circuit detailsElectrical measurement instrument detailsManganinEngineering

Owner:QINGDAO ITECHENE TECH CO LTD

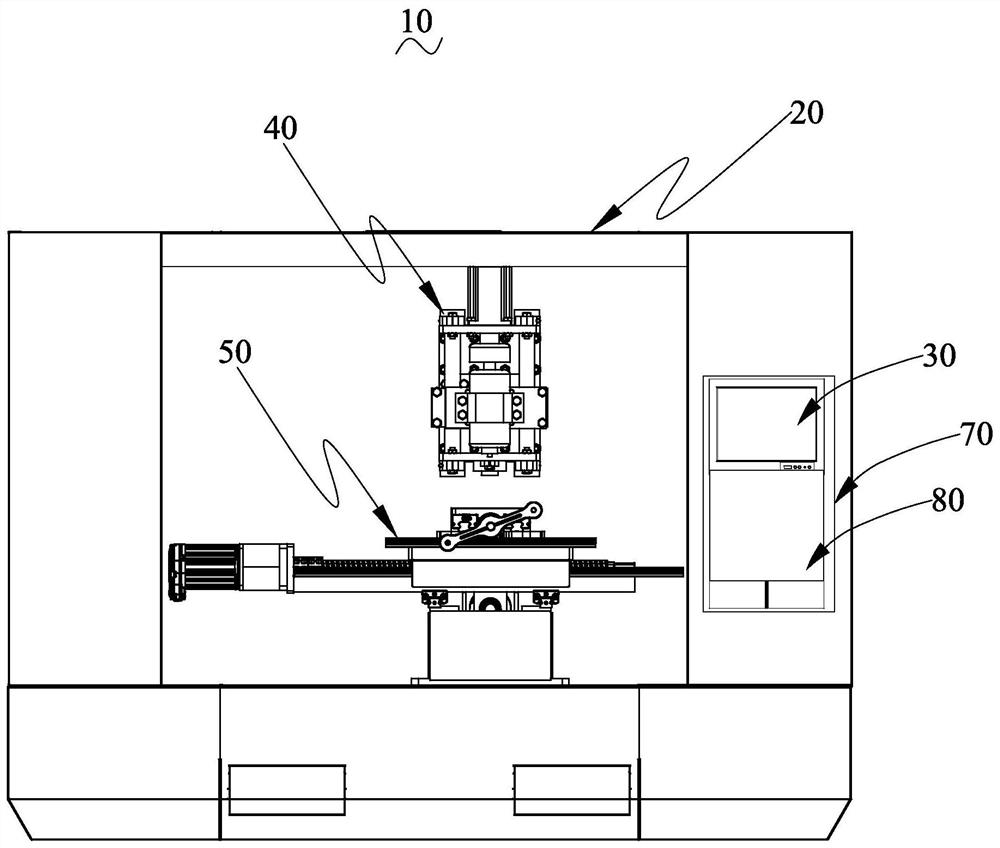

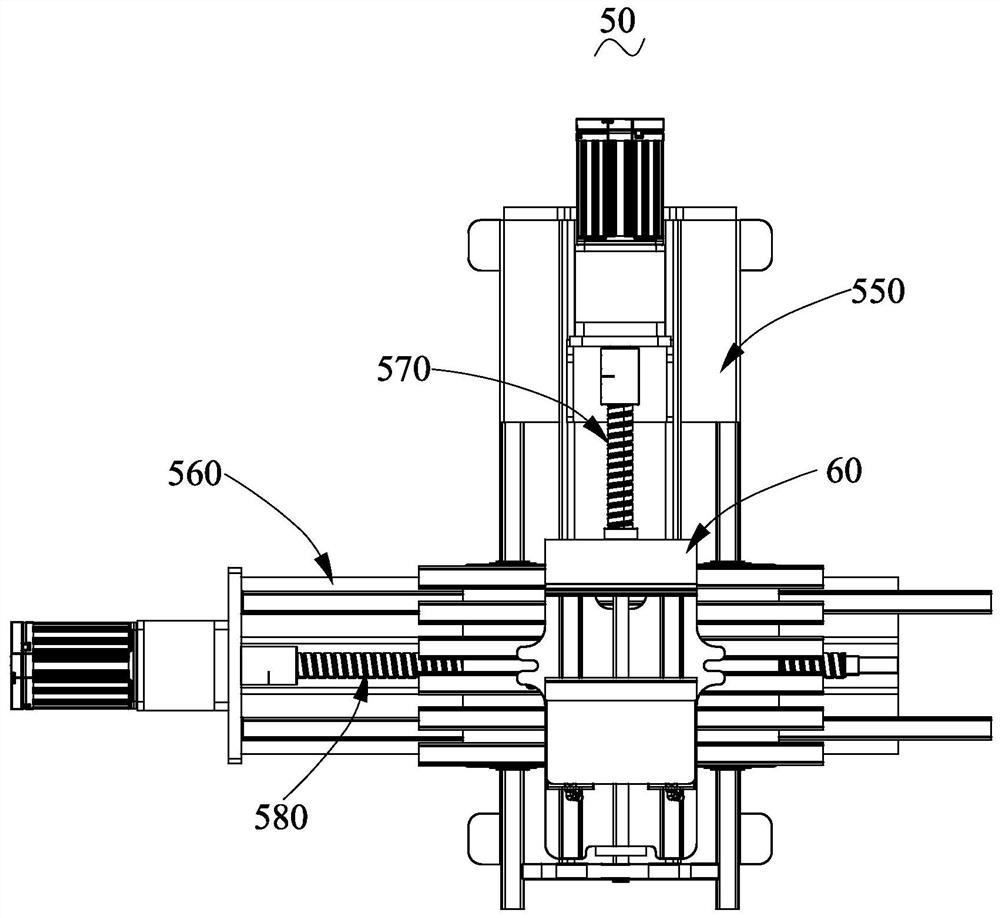

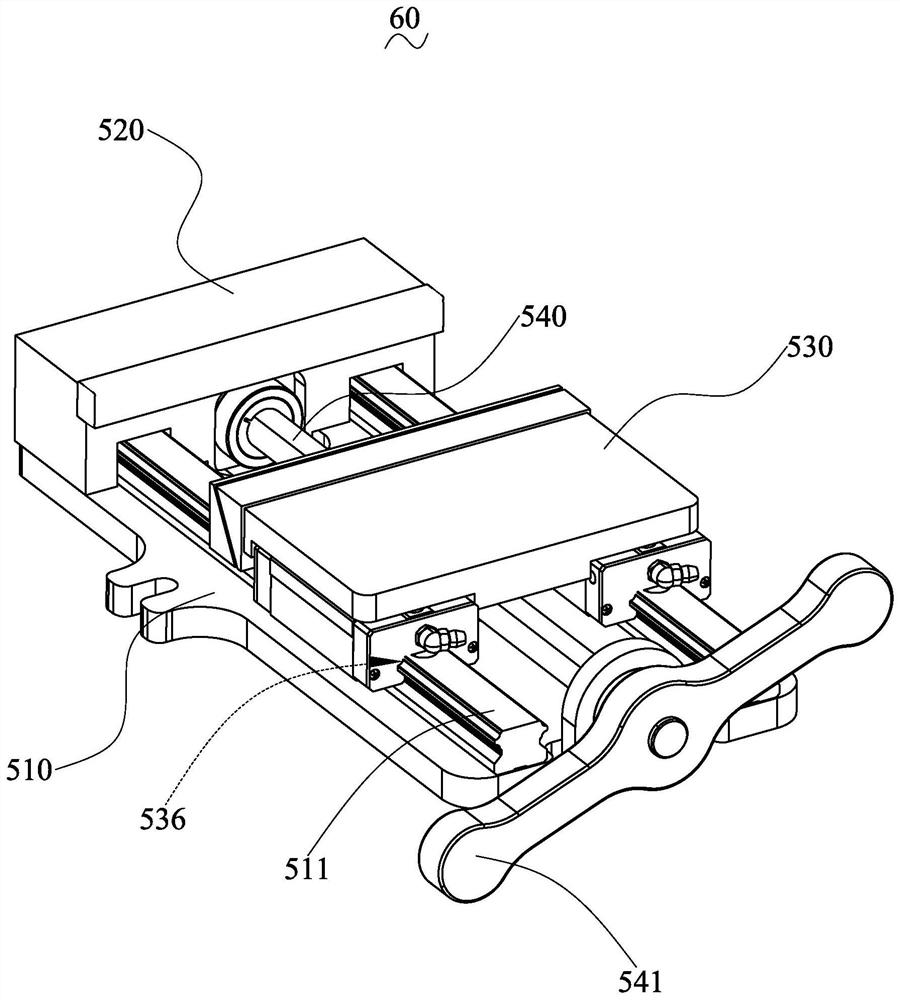

Numerical control machining center with elastic clamping jig

ActiveCN113579792AReduce processing defect rateImprove processing efficiencyPositioning apparatusMetal-working holdersPhysicsEngineering

The invention relates to a numerical control machining center with an elastic clamping jig. The numerical control machining center comprises a numerical control machining machine shell, a touch display screen, a control system, the elastic clamping jig and a machining tool bit system. The elastic clamping jig comprises an elastic clamping mechanism, the elastic clamping mechanism comprises a clamping base, a fixed clamping piece, a movable clamping assembly and a clamping loosening and tightening lead screw, the fixed clamping piece is fixedly arranged on the clamping base, and the movable clamping assembly is arranged on the clamping base in a sliding mode; the movable clamping assembly is in driving connection with the clamping loosening and tightening lead screw; and the movable clamping assembly comprises a first movable block, a second movable block and an adjusting spring, and the first movable block and the second movable block are connected through the adjusting spring. According to the numerical control machining center with the elastic clamping jig, a workpiece is elastically clamped, and the situation that the workpiece is stably clamped through elastic clamping, and meanwhile the workpiece cannot be clamped too tightly; and the machining reject ratio of the workpieces is reduced, and the machining efficiency of the workpieces is improved.

Owner:深圳市锴诚精密模具有限公司

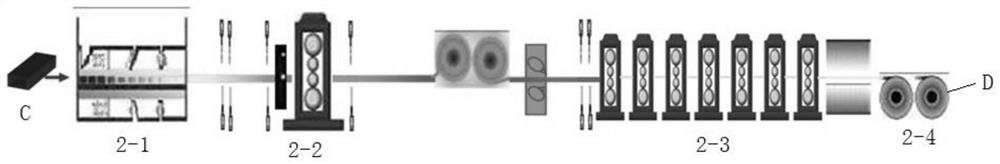

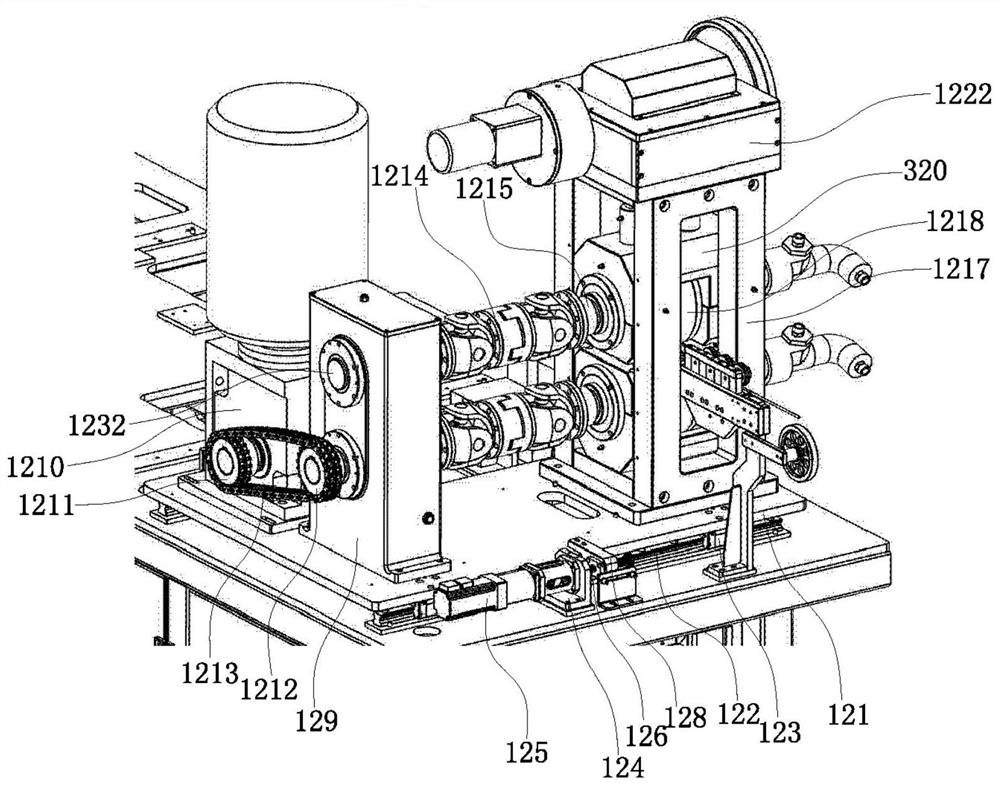

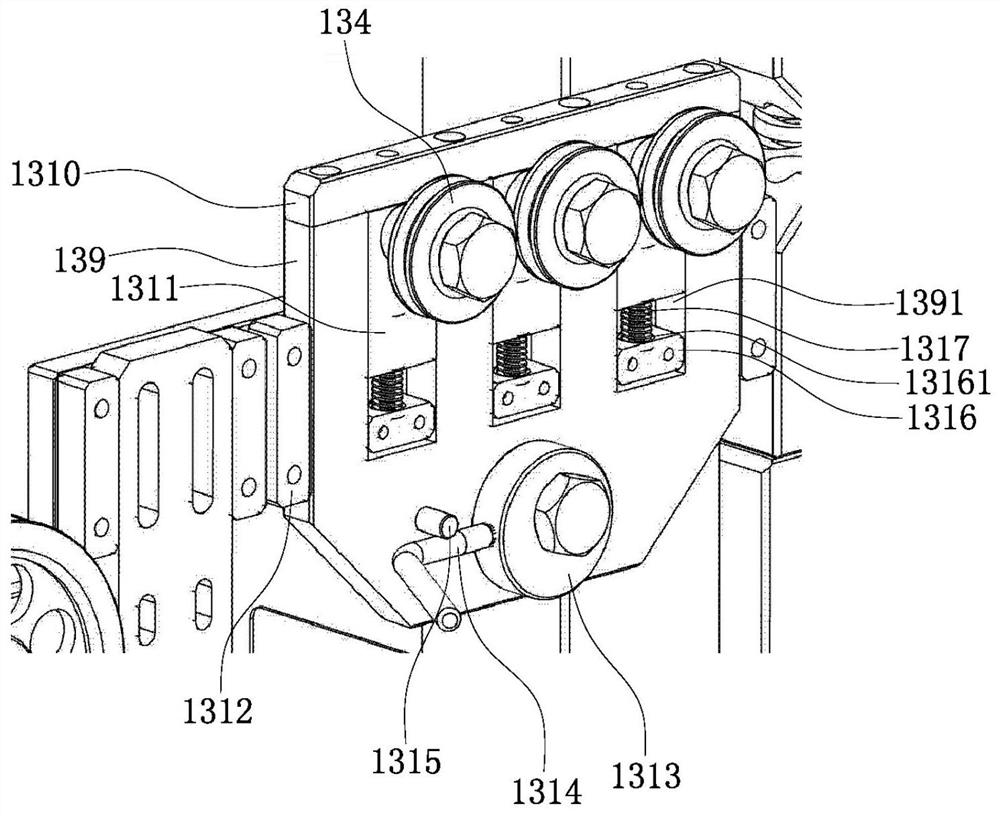

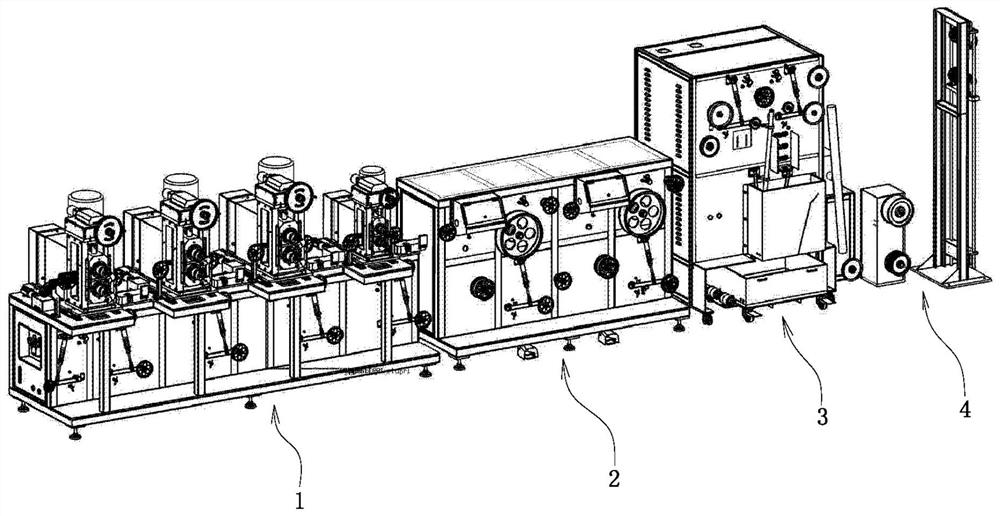

Production equipment for photovoltaic round wire copper strip

PendingCN114074114AAvoid bendingAvoid misalignmentMetal rolling stand detailsMetal rolling arrangementsStructural engineeringCooling fluid

The invention relates to production equipment for a photovoltaic round wire copper strip. The production equipment comprises a calendering mechanism, a drawing mechanism, an annealing and cooling mechanism and a wire storage mechanism which are sequentially arranged in the material feeding direction; The calendering mechanism comprises a first cabinet body, a plurality of rolling assemblies which are transversely and sequentially arranged are arranged on the upper side of the first cabinet body, each rolling assembly is further provided with a guide assembly, and a straightening assembly comprises an input assembly and an output assembly; the input assembly and the output assembly are arranged on the outer sides of the left side block and the right side block correspondingly and arranged above a first buffering assembly and a second buffering assembly correspondingly; and the drawing mechanism comprises a second cabinet body, and a plurality of transversely-arranged drawing assemblies are arranged on the second cabinet body. The application range is widened, bending and dislocation of the copper strip in the processing process can be avoided so that use can be facilitated, meanwhile, the processing reject ratio is greatly reduced, and the effective utilization rate of cooling liquid is increased so that the production cost can be reduced.

Owner:ZHEJIANG TRUMHE NEW MATERIAL CO LTD

40-pin signal transmission cable with distance of 0.8 mm and manufacturing method thereof

InactiveCN112838398ASimple assembly structureEasy to operateCoupling device connectionsElectric cablesElectrically conductive

The invention discloses a 40-pin signal transmission cable with the distance of 0.8 mm and a manufacturing method thereof, the signal transmission cable comprises a connector and an FFC, the conductive end of the FFC is inserted into the connector, the distance between wires of the FFC is 0.8 mm, and the number of the wires of the FFC is 40. After the connector of the flexible flat cable provided by the invention is assembled with the cable, the overall size of the product is reduced, and the use requirement of an ultra-thin product is met; and meanwhile, the assembly structure between the cable and the connector is simple and easy to operate, so that the cost is reduced, and the reject ratio of the manufacturing process is also reduced.

Owner:苏州新亚电通股份有限公司

cnc automatic line

ActiveCN109571144BIncrease productivityReduce labor costsMetal working apparatusPositioning apparatusNumerical controlRobot hand

The invention provides a computerized numerical control machine automatic line. The computerized numerical control machine automatic line comprises a main control box, automatic doors, a ground rail,feeding trolleys, secondary positioning devices, mechanical arms and material taking and cleaning palms, wherein the feeding trolleys are arranged on the ground rail, the secondary positioning devicesare arranged on the feeding trolleys, the material taking and cleaning palm are arranged on the mechanical arm, the automatic doors are arranged on the side edge of the computerized numerical controlmachine, and clamps are arranged in the computerized numerical control machine. The computerized numerical control machine automatic line is arranged on the side edge of the automatic doors, when thefeeding trolleys slide to the computerized numerical control machine precise positions, the automatic doors are automatically opened, machined products on the clamps are taken out by the feeding trolleys, the clamps are cleaned, and after the cleaning is completed, products which is positioned by the secondary positioning devices are installed on the clamps through the material taking and cleaning palms, after the installation is completed, the material taking and cleaning palms exits the automatic doors, the automatic doors are closed, the computerized numerical control machine begins to work; according to the arrangement of the automatic doors, the mechanical arms, and the material taking and cleaning palms arranged on the mechanical arms, the intelligent replacement and assembly of products are realized, the waste chips can be cleaned, the labor cost can be saved, the processing reject ratio can be reduced, and the production efficiency can be improved.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

Display device and manufacturing method thereof

PendingCN112913019AReduce processing defect rateReduce processing timeSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

The present invention relates to a display device manufacturing method and a display device according to same, the method comprising the steps of: placing a plurality of light-emitting elements on a first transfer film; elongating the first transfer film such that the plurality of light-emitting elements are spaced apart from each other; transferring the plurality of light-emitting elements onto a TFT array substrate; and removing the transfer film from the plurality of light-emitting elements.

Owner:SAMSUNG DISPLAY CO LTD

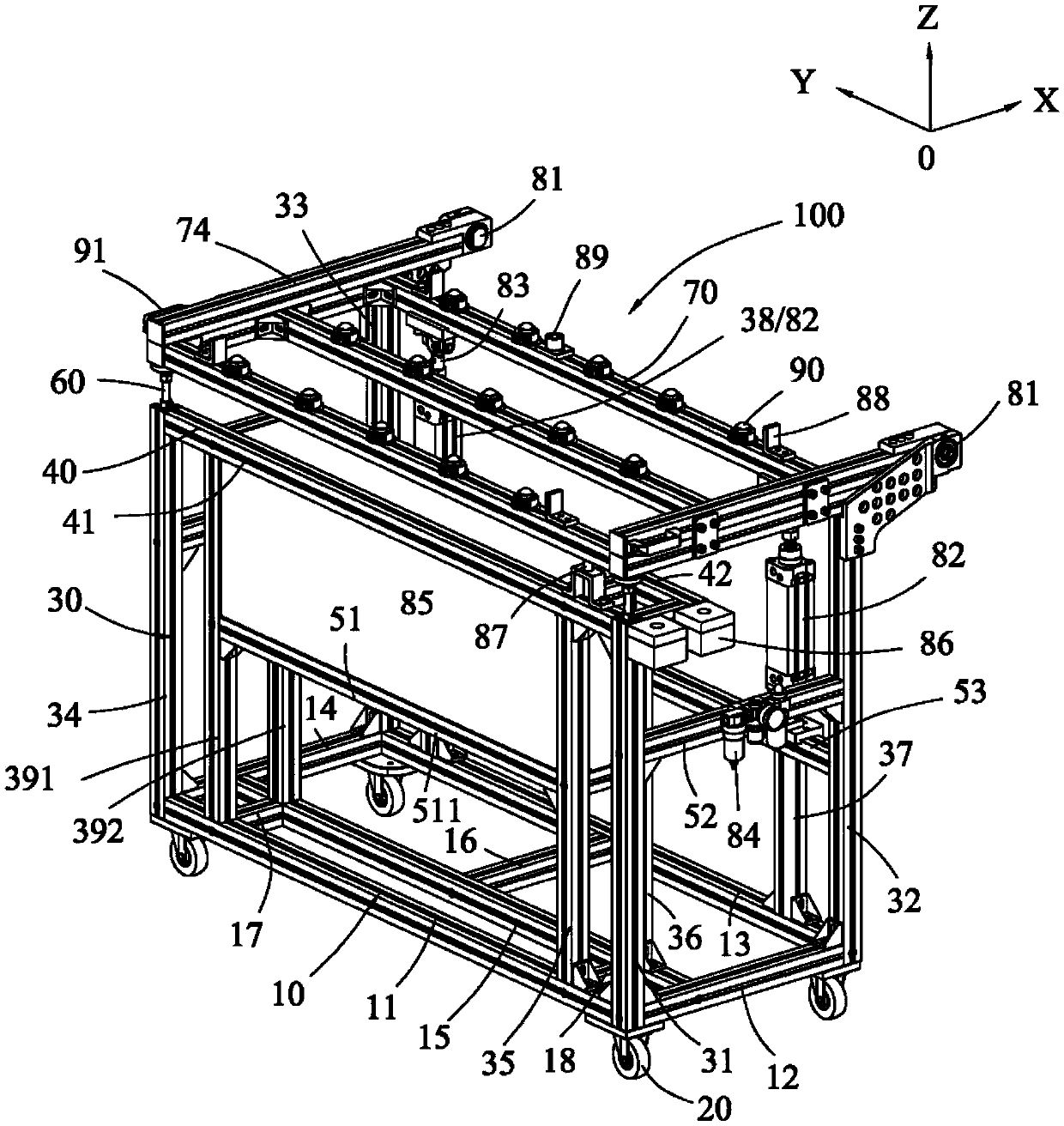

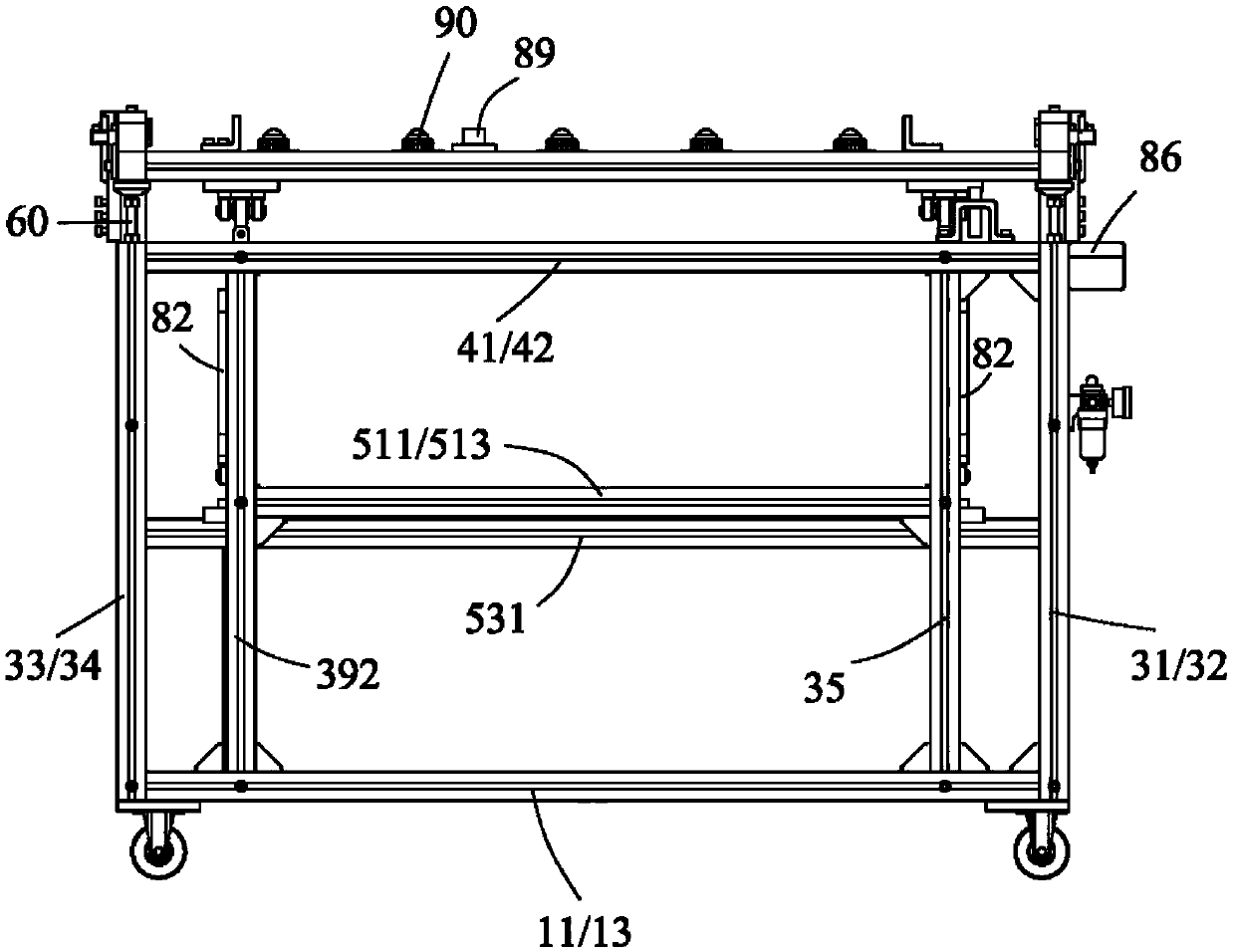

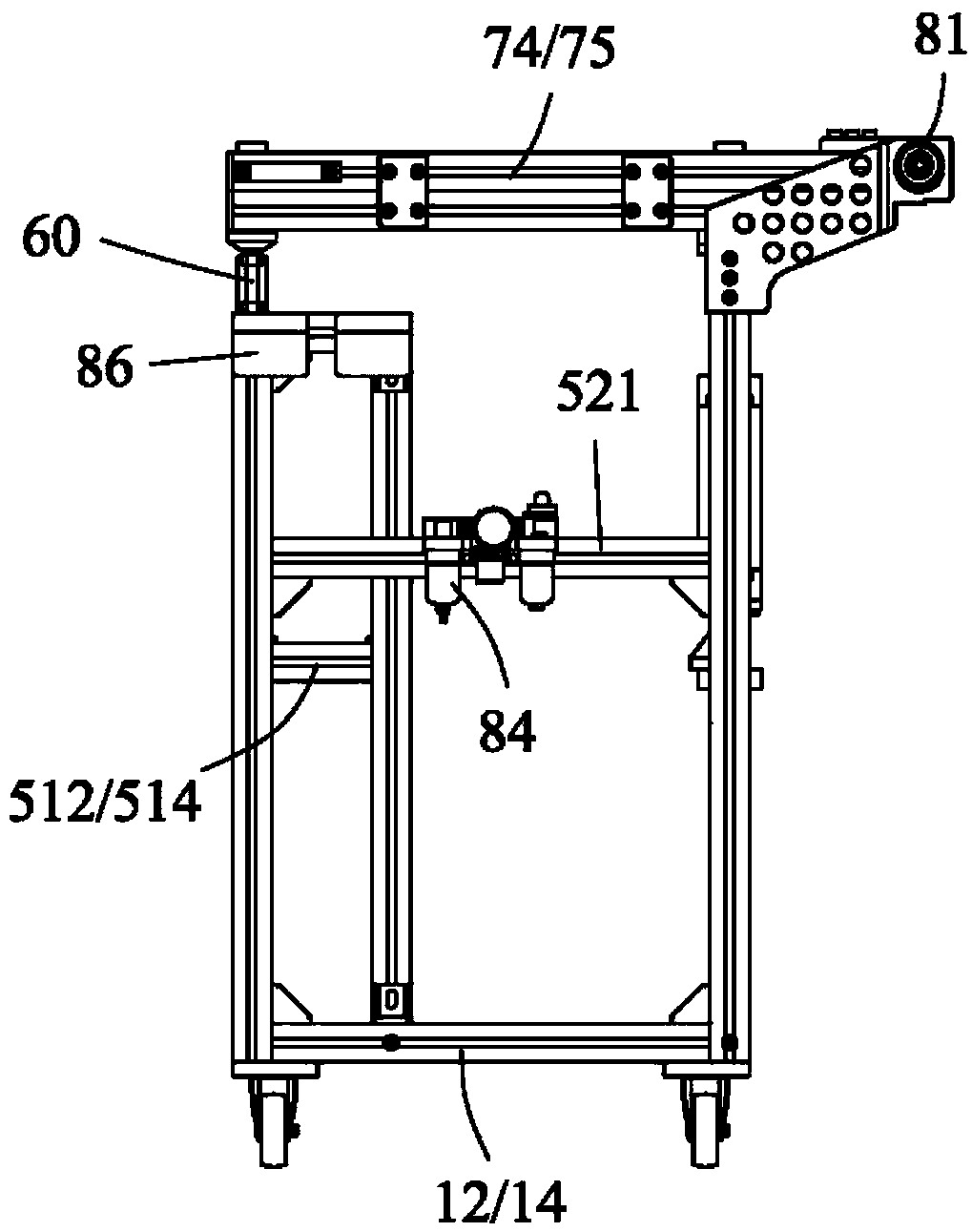

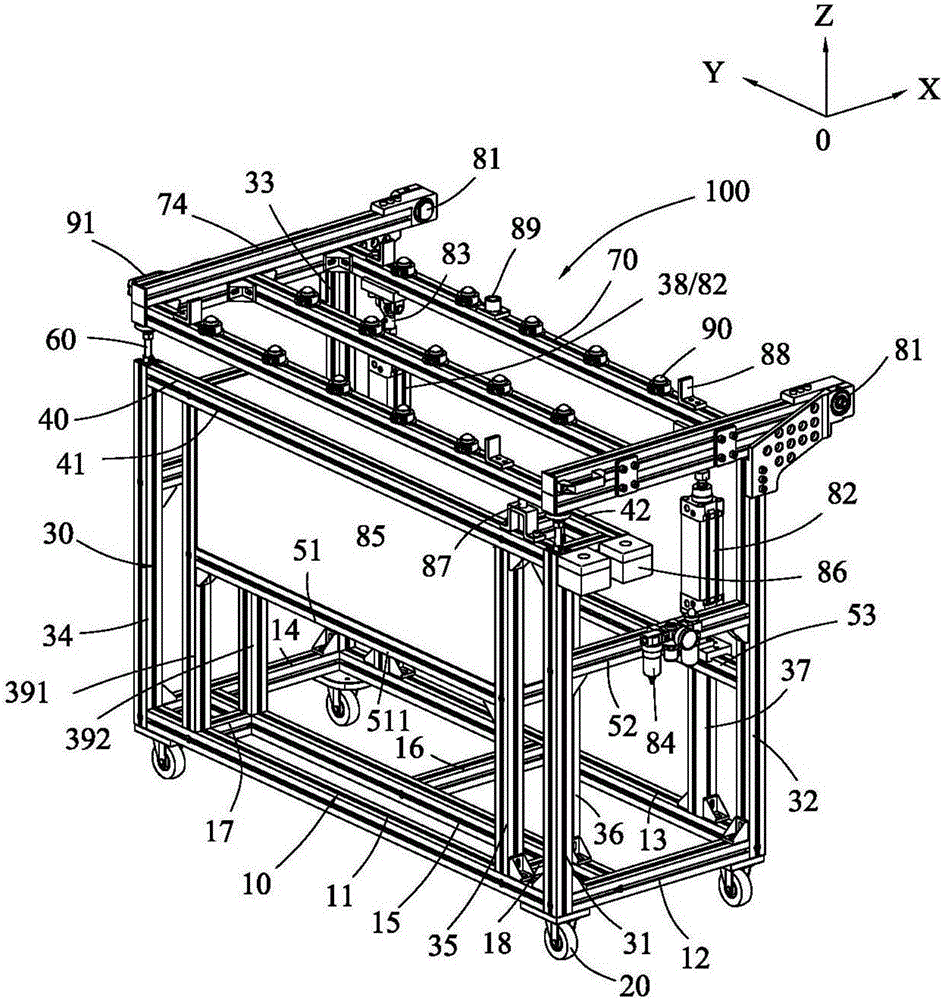

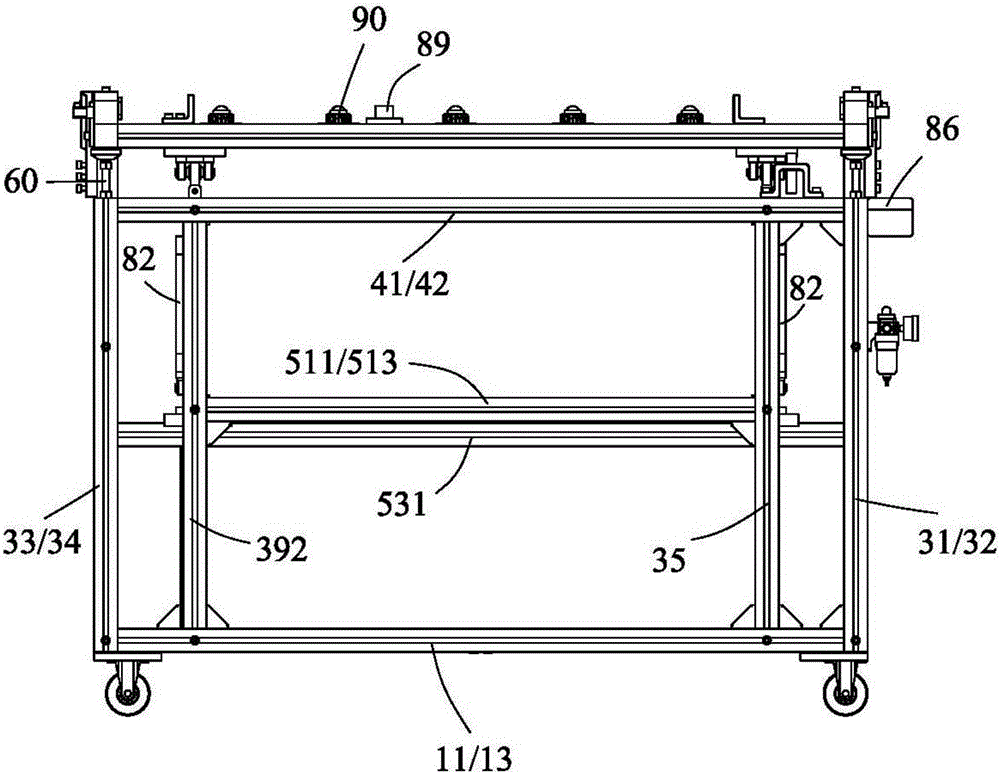

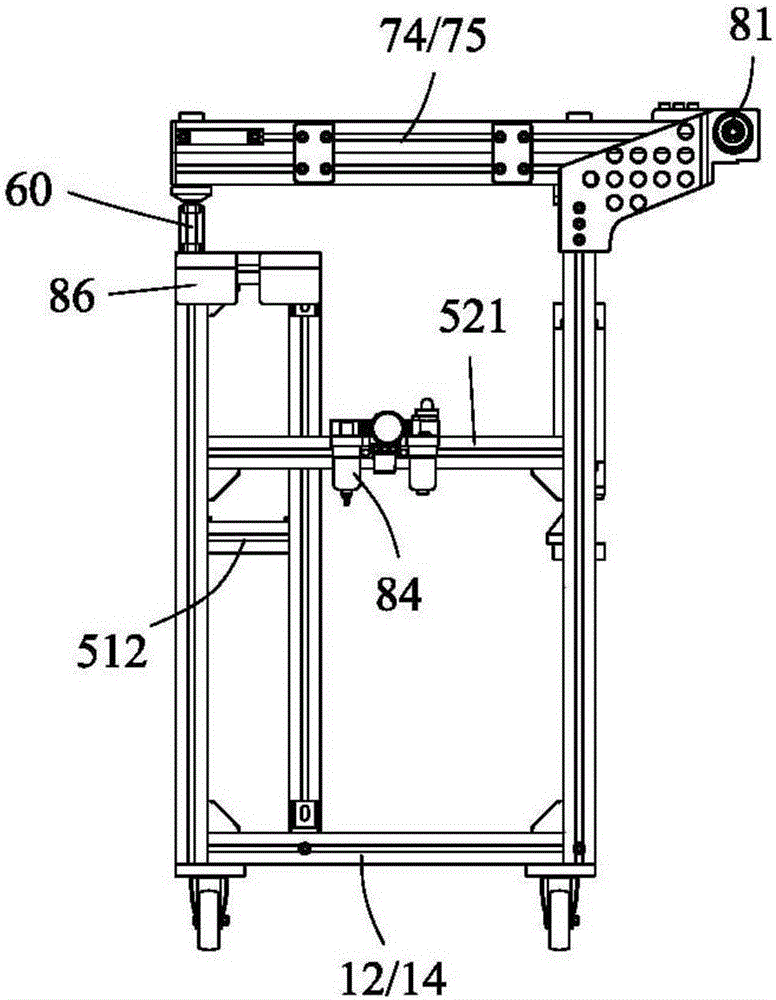

auxiliary support device

ActiveCN106001220BEasy to useDifficult to solveShaping safety devicesUniversal jointElectrical control

The invention provides an assistant supporting device. The assistant supporting device comprises a bottom supporting device, a vertical supporting device, an upper supporting device, a first middle supporting device ,a second middle supporting device, a third middle supporting device, a buffering device, a top supporting device, an electrical control box, an air source processing device, a jacking cylinder, an universal joint device, a plurality of movable baffle plates, an electric chuck, a plurality of steel ball rollers, two operating handles and two rotating bearings, wherein the plurality of movable baffles, the electric chuck, the plurality of steel ball rollers, the two operating handles and the two rotating bearings are fixed to the top supporting device. The assistant supporting device is used in match with a numerically-controlled bending machine, and thus a large sheet metal spare part can be easily bent; the stroke of the air source processing device and the jacking cylinder can be adjusted to easily control the rotating speed and the rotating angle of the machine. With the adoption of the assistant supporting device, the difficulty of workers at workpiece arranging and positioning can be solved, and the fraction defective in the processing of the spare part can be reduced; the difficulty of the workers carrying a large workpiece can be solved; the potential risk that the workers handhold the workpiece during the machine stand processing process can be effectively avoided.

Owner:昆山力盟机械工业有限公司

Assistant supporting device

ActiveCN106001220AEasy to useDifficult to solveShaping safety devicesUniversal jointElectrical control

The invention provides an assistant supporting device. The assistant supporting device comprises a bottom supporting device, a vertical supporting device, an upper supporting device, a first middle supporting device ,a second middle supporting device, a third middle supporting device, a buffering device, a top supporting device, an electrical control box, an air source processing device, a jacking cylinder, an universal joint device, a plurality of movable baffle plates, an electric chuck, a plurality of steel ball rollers, two operating handles and two rotating bearings, wherein the plurality of movable baffles, the electric chuck, the plurality of steel ball rollers, the two operating handles and the two rotating bearings are fixed to the top supporting device. The assistant supporting device is used in match with a numerically-controlled bending machine, and thus a large sheet metal spare part can be easily bent; the stroke of the air source processing device and the jacking cylinder can be adjusted to easily control the rotating speed and the rotating angle of the machine. With the adoption of the assistant supporting device, the difficulty of workers at workpiece arranging and positioning can be solved, and the fraction defective in the processing of the spare part can be reduced; the difficulty of the workers carrying a large workpiece can be solved; the potential risk that the workers handhold the workpiece during the machine stand processing process can be effectively avoided.

Owner:昆山力盟机械工业有限公司

Dual lens drive, dual camera module and optics

ActiveCN110169048BConvenience guaranteedReduce processing defect rateTelevision system detailsPrintersBobbinEngineering

The present embodiment relates to a dual-lens drive device comprising: a housing; a first bobbin arranged to move in a first direction within the housing; and a second bobbin arranged to move along a first direction within the housing a first coil arranged on the first bobbin; a second coil arranged on the second bobbin; a magnet arranged in the housing and facing the first coil and a second coil; a base arranged below the housing; a substrate including a circuit member having a third coil arranged to face the magnet and between the housing and the base; and a support member to attach the housing The body is supported for movement relative to the base plate, wherein the housing is integrally formed.

Owner:LG INNOTEK CO LTD

A wire-drawing processing device for the surface of an asymmetric cylindrical curved surface mold core of an injection mold

InactiveCN104369067BReduce processing timeReduce manpowerGrinding wheel securing apparatusGrinding machinesEngineeringMachining time

The invention relates to the technical field of mould machining, in particular to a wire drawing machining device for the surface of an asymmetric and cylindrical curved surface mould core of an injection mould. The wire drawing machining device comprises a body with a driver, a rotating body connected with the body, a fixed disc installed on the rotating body, a rotation shaft meshed with the fixed disc, an inclined block combined with the rotation shaft, a fixator corresponding to the mould core, abrasive paper fixed to one end of the fixator, and an elastic supporting portion arranged between the body and the fixator. The wire drawing machining device enables the asymmetric and cylindrical curved surface mould core to be machined in a buffing mode, thereby obviously shortening the machining time of a surface subjecting to wire drawing, saving manpower and reducing the machining reject ratio.

Owner:TIANJIN FANJIN MOLD

A positioning structure of the rear y-axis of a bending machine

ActiveCN112170562BImprove the qualified rate of hemmingEffective position positioning fastening effectMetal-working feeding devicesPositioning devicesCircular discMachine

The invention discloses a rear gauge Y-axis positioning structure of a bending machine, comprising a fixed beam and a Y-axis positioning block, and a fixed seat is slidably sleeved on the periphery of the fixed beam; Lifting can effectively facilitate the user to adjust the flexibility when clamping the product body, and at the same time, rotate the position of the rear gauge on the periphery of the connecting rod and use the clamping block to perform positioning, so as to effectively achieve the position and tightening effect of the rear gauge, and through the disc Drive the threaded rod so that the Y-axis positioning block can adjust the Y-axis position through the slider in the chute, so that the auxiliary positioning effect of the product body during bending processing can be more stable, which greatly reduces the product processing defect rate. At the same time, it is further realized to avoid the situation that the positioning size of the positioning edge of the product body is too small or the opposite sex edge cannot be effectively positioned vertically, thereby effectively improving the qualified rate of sheet product hemming.

Owner:深圳市龙诚行实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com