LED liquid crystal display backlight module

A technology of backlight module and liquid crystal display, which is applied in the field of backlight module and can solve the problems of high defect rate of modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

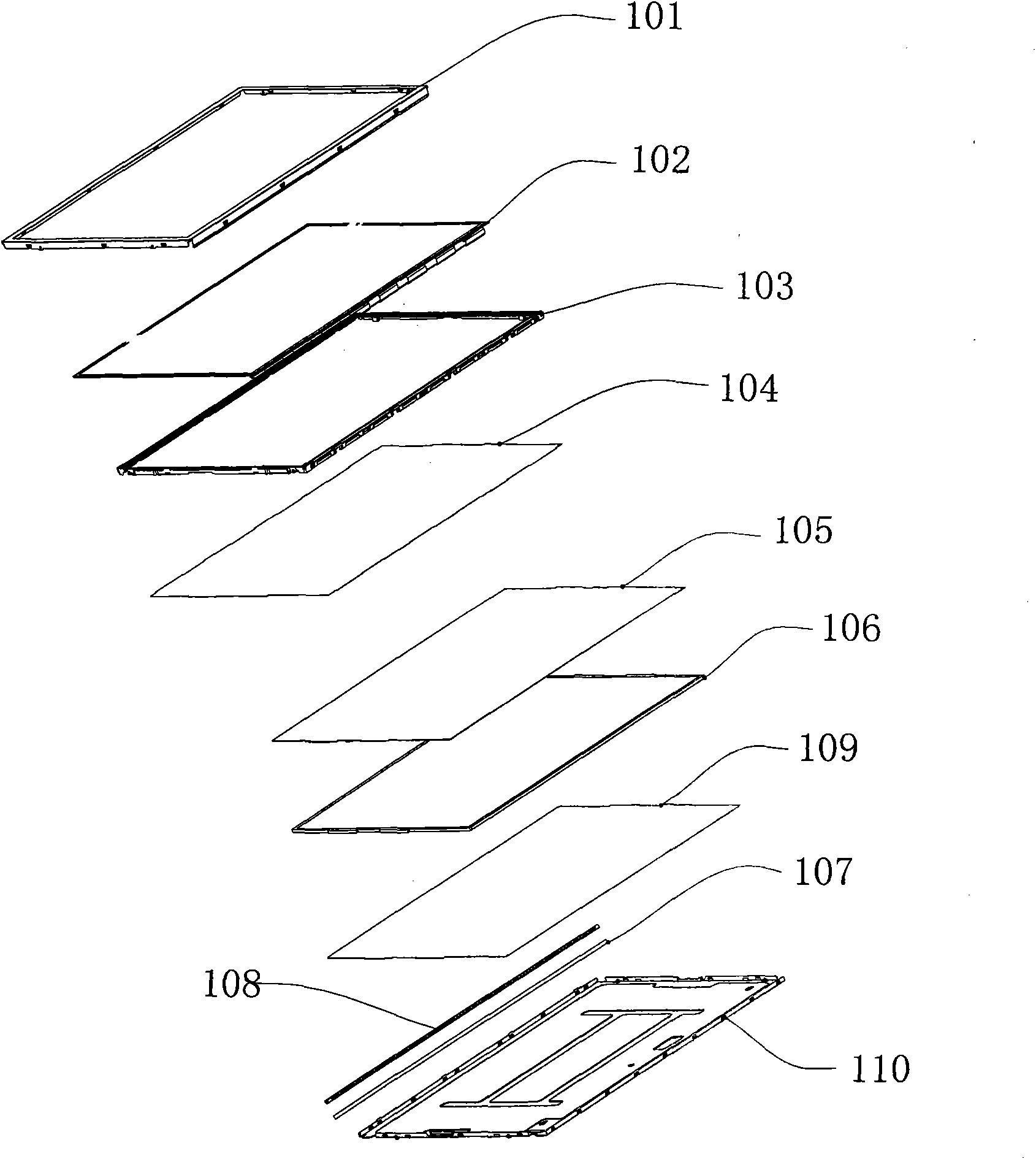

[0025] The present invention proposes an LED liquid crystal display backlight module, including an LED light bar and a light guide plate, an LED light is provided on the LED light bar, and the LED light bar is provided on the back of the light guide plate, corresponding to the position of the LED light There are holes on the light guide plate. The holes include two holes on the front and back of the light guide plate. There are direct-down LED lights at the holes on the back of the light guide plate. Light reflectors.

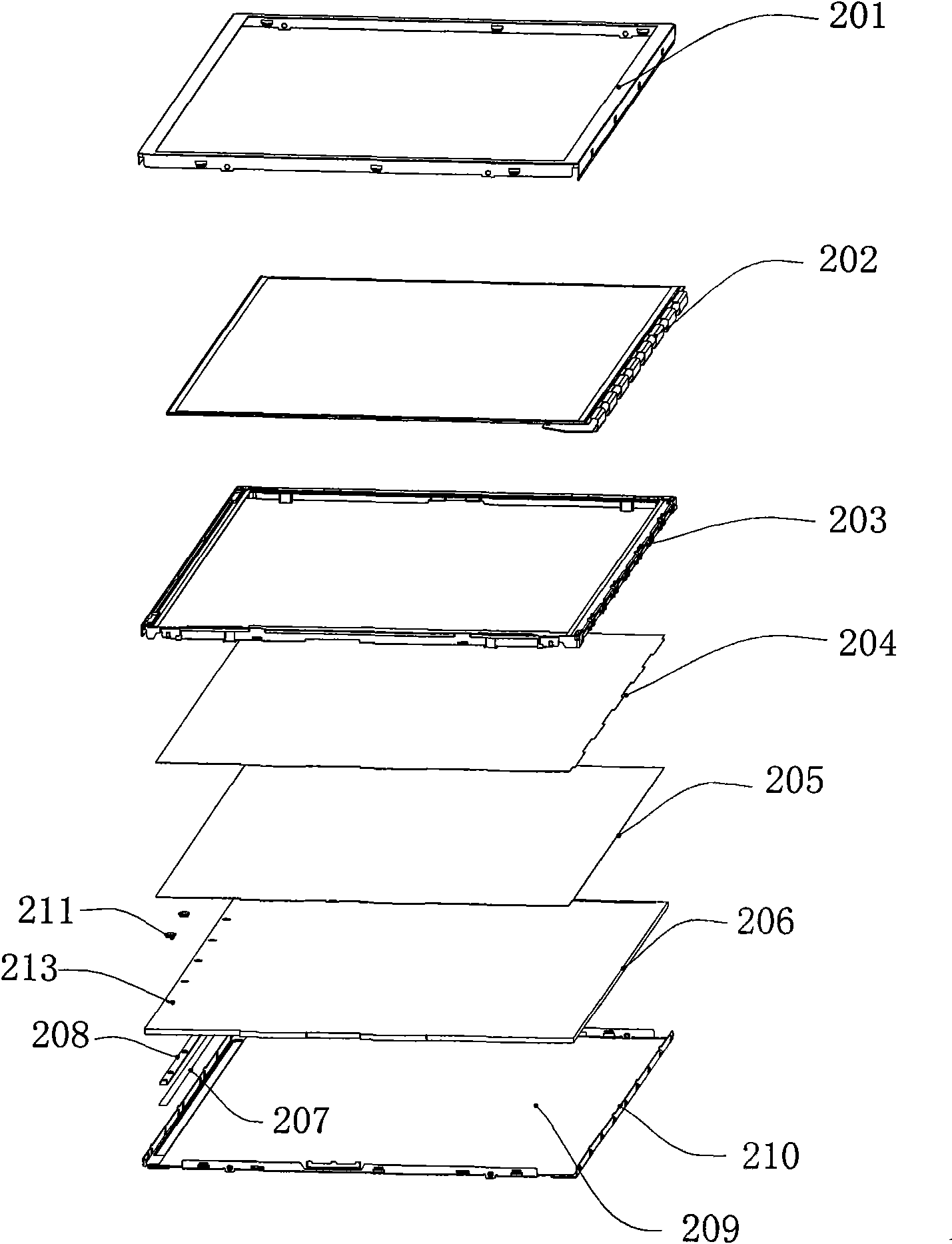

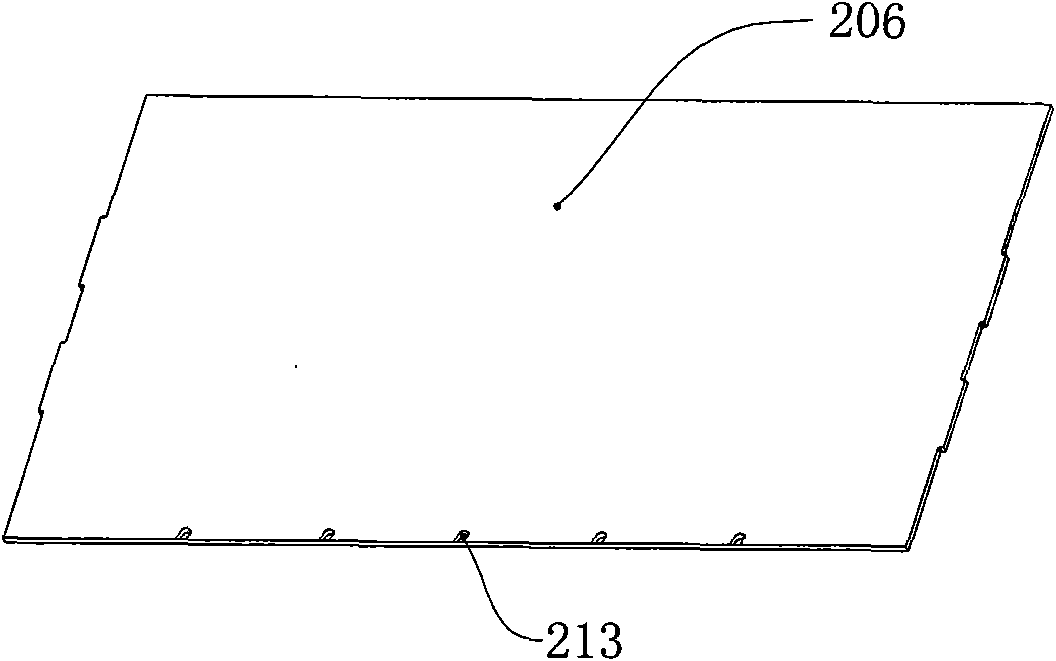

[0026] For an embodiment of the invention see figure 2 and Figure 4 shown. The module from top to bottom is hardware front frame 201, glass (OPEN CELL) 202, plastic middle frame 203, upper diffuser 204, lower diffuser 205, light guide plate 206, LED light bar 208, reflector 209 and back Plate 210 et al. There is thermal conductive glue 207 between the LED light bar and the back plate 210 .

[0027] There are LED lights 212 on the LED light bar 208 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com