Flywheel assembly processing device and method

A processing method and flywheel technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of heavy manual load, low manufacturing accuracy of flywheel discs, and high production costs, reduce monthly waste loss, reduce labor intensity and The effect of reducing the number of workers and the rate of defective product processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

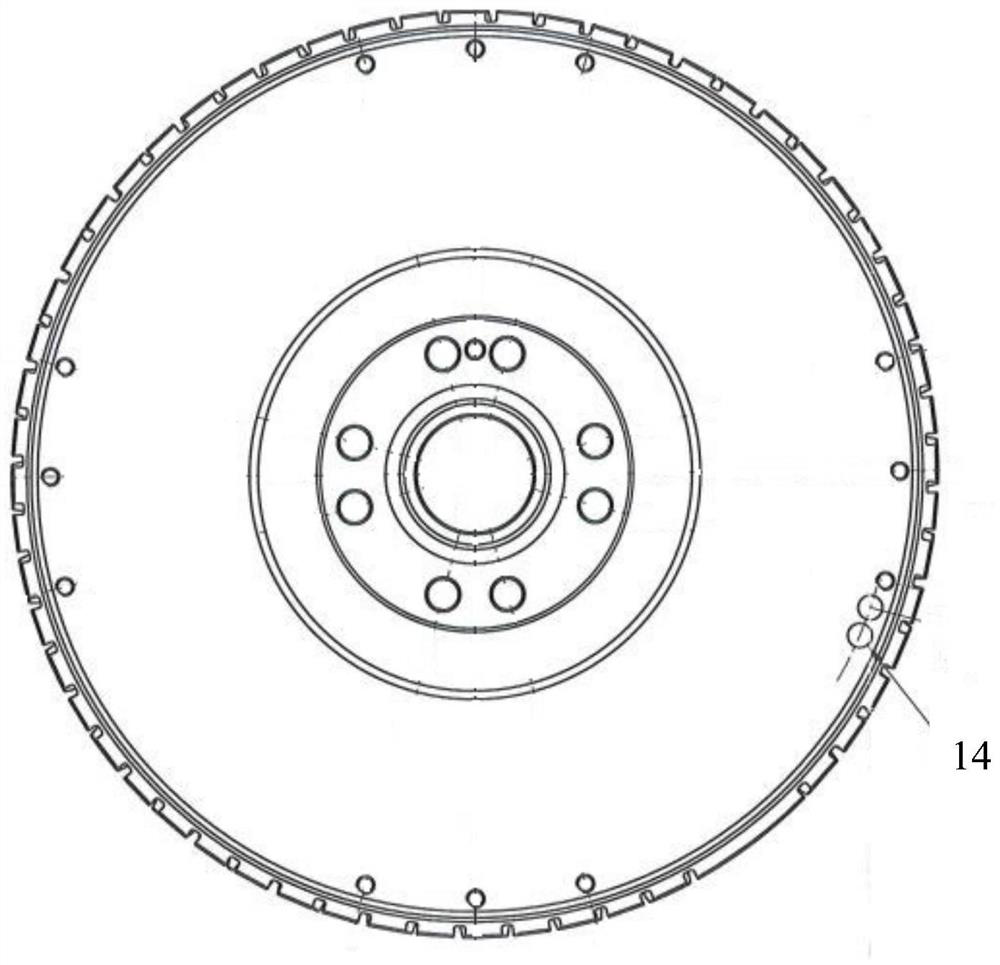

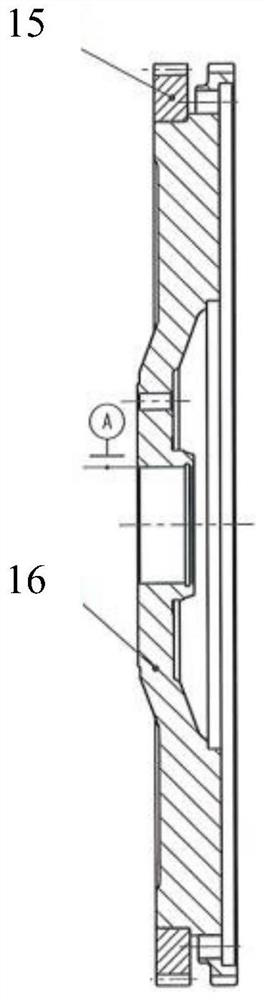

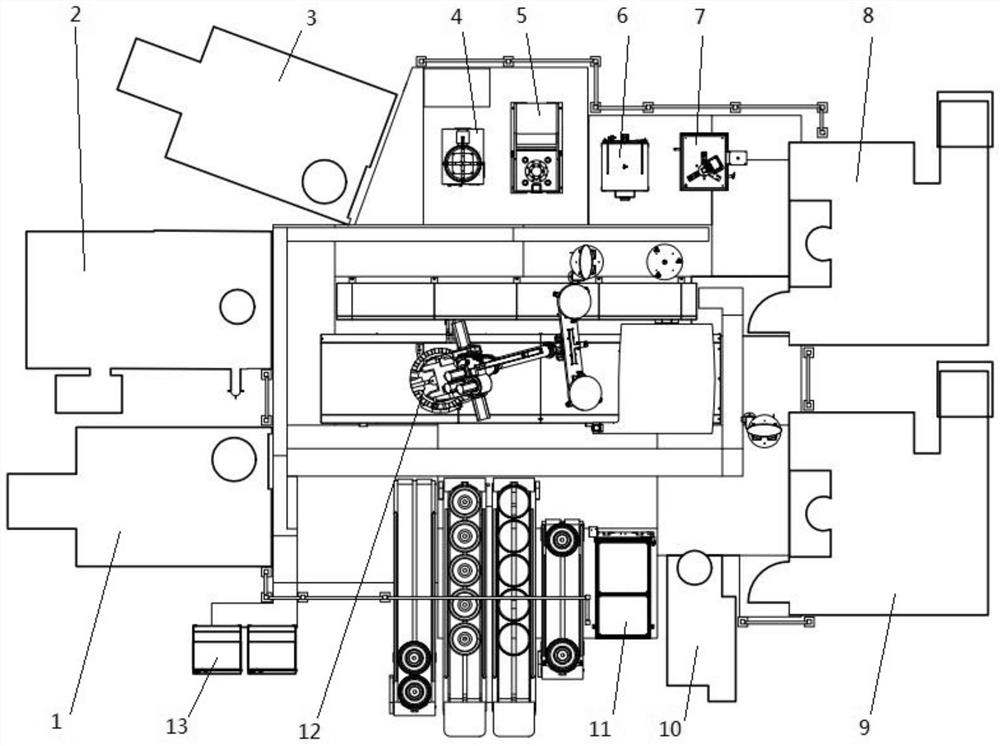

[0027] refer to image 3 , the processing device of the flywheel assembly, including the first vertical lathe 1, the horizontal lathe 2, the second vertical lathe 3, the ring gear heating device 4, the press 5, the cleaning table 6, the online detection device 7, the first vertical lathe 8 , The second vertical plus 9, dynamic balancing equipment 10, infrared scanning and laser marking machine 11, robot 12, automation system 13, dynamic balancing hole 14, ring gear 15, flywheel 16.

[0028] Processing method of flywheel assembly:

[0029] After the system is started, firstly the first vertical lathe 1 opens the protective door after finishing the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com