A wire-drawing processing device for the surface of an asymmetric cylindrical curved surface mold core of an injection mold

A technology for injection molding and wire drawing processing, which is applied in the direction of fixed grinding wheel devices, metal processing equipment, manufacturing tools, etc. It can solve the problems of difficult grinding, consuming a lot of time and manpower, poor corrosion treatment, etc., and achieve the effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

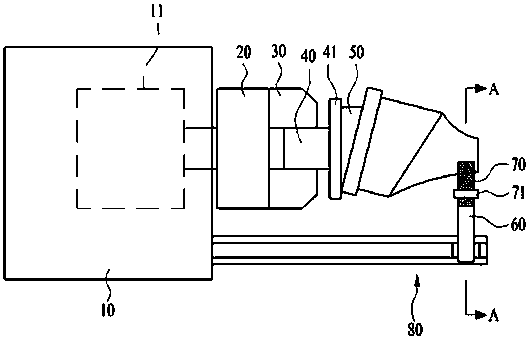

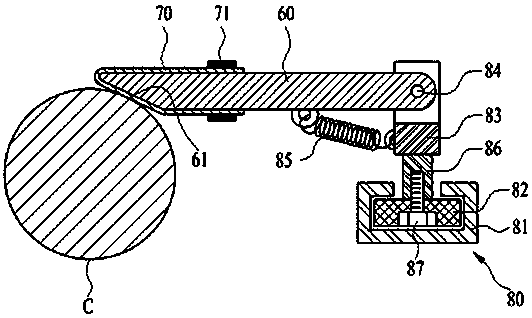

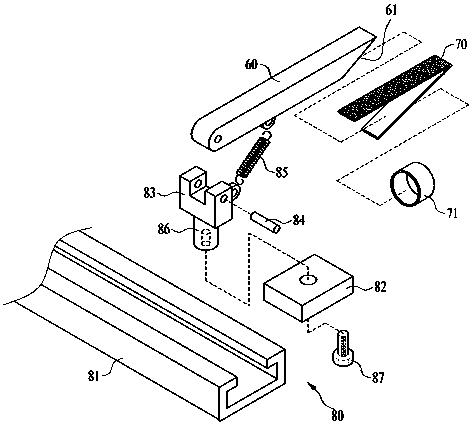

[0018] see Figure 1 to Figure 4 , this specific embodiment adopts the following technical solutions: it includes a body 10 with a driver, a rotating body 20 connected to the body 10, a fixed disk 30 mounted on the rotating body 20, a rotating shaft 40 engaged with the fixed disk 30, and a rotating The inclined block 50 combined with the shaft 40 , the holder 60 corresponding to the mold core C, the sandpaper 70 fixed at the end of the holder 60 , and the elastic support part 80 arranged between the body 10 and the holder 60 .

[0019] Wherein, the main body 10 is provided with a driver 11, and the driver 11 drives the rotating body 20, thereby driving the mold core C. The fixed disk 30 is arranged at the end of the rotating body 20 , and functions to fix the rotating shaft 40 and also loosen the rotating shaft 40 . The rotating shaft 40 is fixed on the fixed disk 30 , and the end of the rotating shaft 40 is provided with a disk 41 to facilitate the installation of the tiltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com