Adjustable double torsion mirror box and device for measuring yarn appearance parameters

A parameter measurement and adjustable technology, applied in measurement devices, color measurement devices, optical devices, etc., can solve the problems of expanding instrument space, increasing equipment costs, unable to obtain accurate yarn information, etc., to achieve accurate and complete reflection, The effect of high reliability comprehensive analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

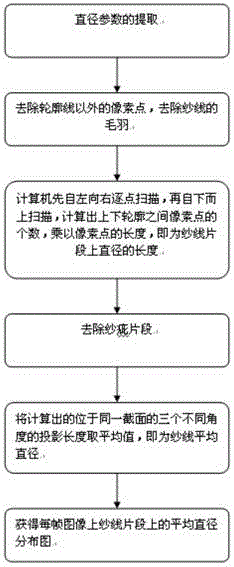

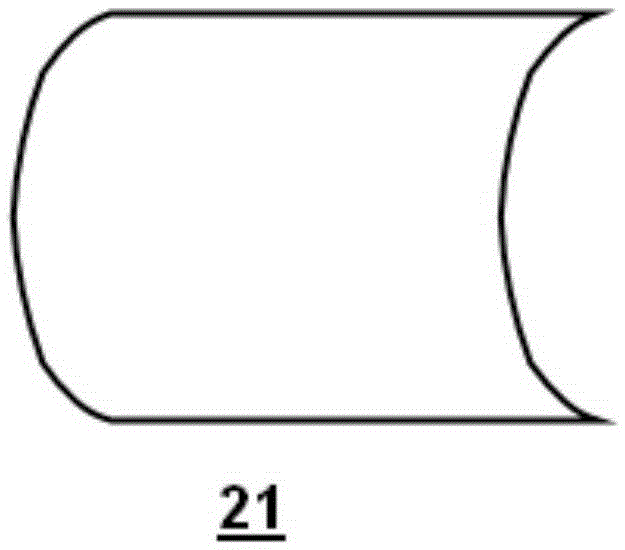

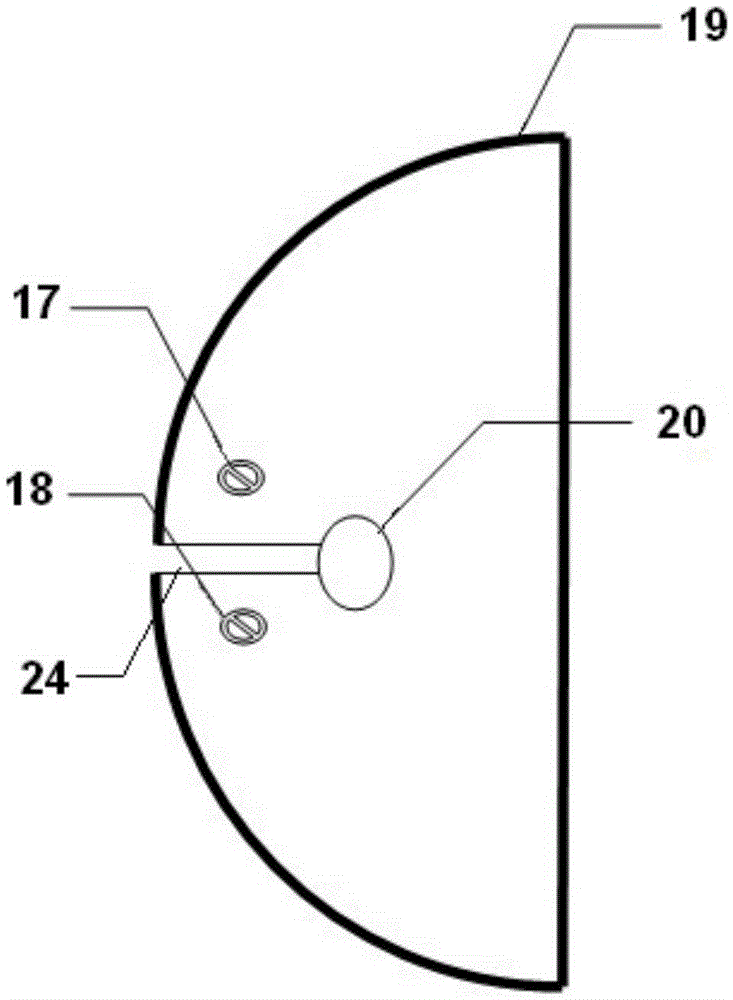

[0036] see figure 1 , figure 2 , image 3 , Figure 4 Shown is an adjustable double-twist mirror box for measuring yarn appearance parameters. The adjustable double-twist mirror box is a hollow semi-cylindrical closed structure, including a diffuse reflection arc cover 21 with a semicircular cross section and two A semicircular fixed plate 19, the diffuse reflection arc cover plate 21 constitutes the arc surface of the semi-cylindrical body, and the two fixed plates 19 form two end faces of the semi-cylindrical body respectively; Arc-shaped, the length of the diffuse reflective arc cover 21 is just equal to the distance between the two fixed plates 19, the fixed plate 19 and the diffuse reflective arc cover 21 are well closed to form a sealed and complete space, thereby ensuring the lighting conditions of stability. The color of the inner surface of the diffuse reflection arc cover plate 21 is equivalent to the background color, which is convenient for image processing. T...

Embodiment 2

[0045] see Figure 5 A device for measuring yarn appearance parameters is shown, including a yarn guiding hole 1, a yarn guiding device 2, a yarn guiding wheel 3, the adjustable double-twisted mirror box 4 in Example 1, and a yarn guiding wheel arranged in sequence 5. The yarn guide wheel 6, the yarn guide outlet hole 7, the tension control device 8 and the winding device 9, and the adjustable double twist mirror box 4 is also connected to the computer (not shown in the figure);

[0046] The yarn guide hole 1 and the yarn guide outlet hole 7 play the role of controlling the direction of yarn movement; the yarn guide device 2 is composed of a pair of pulleys, which mainly play the role of controlling the yarn tension and movement direction, and are mainly controlled by a variable speed motor; The wheels 3 and 5 are located at the same horizontal position, so that the yarn can move in a straight line through the double-torsion mirror test area; the tension control device 8 is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com